Die datar, hot stamping, multiGRAFOTRONIC

350 200254G

Die datar, hot stamping, multi

GRAFOTRONIC

350 200254G

VB ditambah PPN

€67.500

Kondisi

Bekas

Lokasi

Kruszyn Krajeński

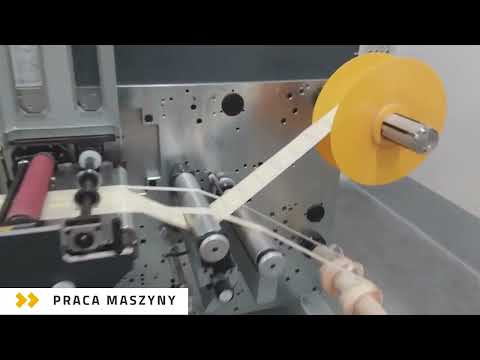

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Die datar, hot stamping, multi

- Pabrikan:

- GRAFOTRONIC

- Model:

- 350 200254G

- Kondisi:

- sangat baik (bekas)

- Fungsi:

- berfungsi sepenuhnya

Harga & Lokasi

VB ditambah PPN

€67.500

- Lokasi:

- Ceramiczna 15, 86-005 Białe Błota, PL

Hubungi

Rincian penawaran

- ID iklan:

- A18949116

- Pembaruan:

- terakhir pada 29.12.2025

Deskripsi

Segment I – Unwinder with Stabilizing Table

The first segment ensures stable guidance of the material web. It is equipped with shafts that allow both lamination and delamination of the face from the liner or other substrate. It features a laminator with precise pressure adjustment.

Additional features:

• Each segment has a festoon mechanism, enabling continuous operation and eliminating the need to stop the machine during flatbed die-cutting.

• Servo-driven pull rollers provide precise material control, located within the station as well.

Segment II – Central Unit (Die-Cutter)

The core of the machine is a flatbed die-cutter, which enables both cutting and embossing operations.

It is equipped with:

• Hot stamping system – a heated plate with a mounted die enables the application of decorative finishes.

• Upper foil unwinders for additional material processing.

• Manual pressure adjustment – four independent gauges provide complete process control, which is especially important for irregular dies and unconventional applications.

• Lower cart as an alternative to festoon system – applied depending on the specific job requirements.

Segment III – Puncher

The third segment handles the separation of the cut labels and their transport to the receiving tray.

• Puncher – ensures precise separation of individual labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and rewinders ensure smooth guidance of additional material.

Segment IV – Rewinder

The final segment is responsible for the finished material’s final rewinding. Equipped with:

Dusdpfewck U Rex Abhon

• Two shafts – enabling simultaneous or alternate rewinding of the finished product.

• Web tensioning system (nip and tensioning rollers) – ensures stable material handling.

• Rotary knife slitting station.

• Matrix waste removal system.

• Web sensors located under each festoon for optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the included tablet.

• Register sensor system – aligns pre-printed material with high precision, ensuring production accuracy and repeatability.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

The first segment ensures stable guidance of the material web. It is equipped with shafts that allow both lamination and delamination of the face from the liner or other substrate. It features a laminator with precise pressure adjustment.

Additional features:

• Each segment has a festoon mechanism, enabling continuous operation and eliminating the need to stop the machine during flatbed die-cutting.

• Servo-driven pull rollers provide precise material control, located within the station as well.

Segment II – Central Unit (Die-Cutter)

The core of the machine is a flatbed die-cutter, which enables both cutting and embossing operations.

It is equipped with:

• Hot stamping system – a heated plate with a mounted die enables the application of decorative finishes.

• Upper foil unwinders for additional material processing.

• Manual pressure adjustment – four independent gauges provide complete process control, which is especially important for irregular dies and unconventional applications.

• Lower cart as an alternative to festoon system – applied depending on the specific job requirements.

Segment III – Puncher

The third segment handles the separation of the cut labels and their transport to the receiving tray.

• Puncher – ensures precise separation of individual labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and rewinders ensure smooth guidance of additional material.

Segment IV – Rewinder

The final segment is responsible for the finished material’s final rewinding. Equipped with:

Dusdpfewck U Rex Abhon

• Two shafts – enabling simultaneous or alternate rewinding of the finished product.

• Web tensioning system (nip and tensioning rollers) – ensures stable material handling.

• Rotary knife slitting station.

• Matrix waste removal system.

• Web sensors located under each festoon for optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the included tablet.

• Register sensor system – aligns pre-printed material with high precision, ensuring production accuracy and repeatability.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2020

Kirim permintaan

Telepon & Faks

+48 52 37... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Kaunas

Kaunas

10.087 km

Mesin cetak flexographic

MPSEF 330/ 7 color

MPSEF 330/ 7 color

Iklan kecil

Langenfeld (Rheinland)

Langenfeld (Rheinland)

11.262 km

Mesin cetak digital

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

Iklan kecil

Leinfelden-Echterdingen

Leinfelden-Echterdingen

11.163 km

Mesin Grafis FGT - Konversi

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

Iklan kecil

München

München

10.997 km

PITNEY BOWES DI425

Pitney BowesDI425

Pitney BowesDI425

Iklan kecil

Bad Kreuznach

Bad Kreuznach

11.227 km

Mesin cetak fleksografi

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

Iklan kecil

Kaunas

Kaunas

10.087 km

Rewer

Jurmet

Jurmet

Iklan kecil

Leinfelden-Echterdingen

Leinfelden-Echterdingen

11.163 km

Mesin Grafis FGT - Konversi

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

Iklan kecil

Leinfelden-Echterdingen

Leinfelden-Echterdingen

11.163 km

Mesin Grafis FGT - Penyelesaian Label

ROTOFLEXR 1300

ROTOFLEXR 1300

Iklan kecil

Helmstedt

Helmstedt

10.966 km

Mesin jahit otomatis

Müller Martini3210

Müller Martini3210

Iklan kecil

Dettelbach

Dettelbach

11.070 km

Mesin penyusut (pengelasan sudut + terowongan)

SmipackWS 560 A + T 450

SmipackWS 560 A + T 450

Iklan Anda telah berhasil dihapus

Terjadi kesalahan