Depaneling / Pemrosesan PCBSystemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Depaneling / Pemrosesan PCB

Systemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Tahun pembuatan

2026

Kondisi

Baru

Lokasi

Kronberg im Taunus

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Depaneling / Pemrosesan PCB

- Pabrikan:

- Systemtechnik Hölzer GmbH

- Tahun pembuatan:

- 2026

- Kondisi:

- baru

- Fungsi:

- berfungsi sepenuhnya

Harga & Lokasi

- Lokasi:

- Westerbachstraße 4, 61476 Kronberg im Taunus, Deutschland

Hubungi

Rincian penawaran

- ID iklan:

- A18369436

- Nomor referensi:

- LOW4233 RD XL Leiterplatten Nutzentrenner

- Pembaruan:

- terakhir pada 26.01.2026

Deskripsi

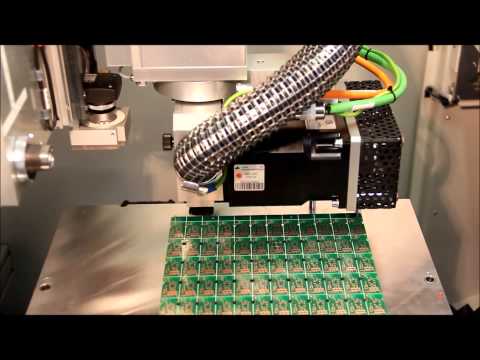

Semi-automatic depaneling / Base unit with parallel shuttle

The dynamic depaneler LOW 4322 XL is specifically designed for medium to high product volumes and meets the increasing demands of modern production processes. Panels made of various PCB materials are separated using low-dust, low-stress sawing and milling techniques, ensuring maximum product flexibility, precision, and throughput. High-dynamic linear motor axes, tools, and grippers meet the highest quality standards and guarantee the depaneler’s long service life and reliability.

Semi-automatic depaneling – tailor-made solutions

The LOW 4322 XL depaneler enables rapid product changeovers while maintaining short separation and handling times. The PCB panel is loaded via a parallel shuttle, and clamped with a pin-clamping technique, optionally combined with vacuum suction cups as needed.

Made in Germany

Machine features:

• Shaft and disc tool separation module on the Z-axis (automatic rotation 0-90 degrees)

• X-Y cross-table module featuring linear motor technology with high-resolution measurement system

• Dual loading module configured as a parallel shuttle, separate left and right sides with sliding doors

• Steel welded frame with two maintenance doors – left and right; ESD-safe design

• Standard vision system base module for teach-in programming

• Working area: 520 x 480mm

• Automatic milling cutter length detection

• Remote maintenance/support via remote connection

• Touch IPC with Windows 10 Pro operating system

• Laser axis measurement including log/report

• Air ionization

• Milling cutter breakage control (only for shaft milling tools)

Djdpfx Abevuw R Rshekh

• Provisions for vacuum clamping technology

• ESD powder coating, RAL 9002, for cover and sliding doors

An optional dust extraction unit can be offered retrofitted upon request.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

The dynamic depaneler LOW 4322 XL is specifically designed for medium to high product volumes and meets the increasing demands of modern production processes. Panels made of various PCB materials are separated using low-dust, low-stress sawing and milling techniques, ensuring maximum product flexibility, precision, and throughput. High-dynamic linear motor axes, tools, and grippers meet the highest quality standards and guarantee the depaneler’s long service life and reliability.

Semi-automatic depaneling – tailor-made solutions

The LOW 4322 XL depaneler enables rapid product changeovers while maintaining short separation and handling times. The PCB panel is loaded via a parallel shuttle, and clamped with a pin-clamping technique, optionally combined with vacuum suction cups as needed.

Made in Germany

Machine features:

• Shaft and disc tool separation module on the Z-axis (automatic rotation 0-90 degrees)

• X-Y cross-table module featuring linear motor technology with high-resolution measurement system

• Dual loading module configured as a parallel shuttle, separate left and right sides with sliding doors

• Steel welded frame with two maintenance doors – left and right; ESD-safe design

• Standard vision system base module for teach-in programming

• Working area: 520 x 480mm

• Automatic milling cutter length detection

• Remote maintenance/support via remote connection

• Touch IPC with Windows 10 Pro operating system

• Laser axis measurement including log/report

• Air ionization

• Milling cutter breakage control (only for shaft milling tools)

Djdpfx Abevuw R Rshekh

• Provisions for vacuum clamping technology

• ESD powder coating, RAL 9002, for cover and sliding doors

An optional dust extraction unit can be offered retrofitted upon request.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2018

Kirim permintaan

Telepon & Faks

+49 6173 ... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Matelica (MC)

Matelica (MC)

10.962 km

MESIN PEMOTONGAN LASER - PEMOTONGAN LASER SERAT

PRIMA POWERPLATINO FIBER 1530

PRIMA POWERPLATINO FIBER 1530

Iklan kecil

Butzbach

Butzbach

11.159 km

Pusat mesin

Starrag-HeckertHEC500D

Starrag-HeckertHEC500D

Iklan kecil

Jerman

Jerman

11.207 km

Sistem pelapisan Venjakob Perfect, OIR, AirJet, UV

VenjakobVEN SPRAY and Drying, UV Line

VenjakobVEN SPRAY and Drying, UV Line

Iklan kecil

Borken

Borken

11.250 km

Kaca laminating baris dengan 2 pemanas

Tool-TempHVD-G02

Tool-TempHVD-G02

Iklan kecil

Burghaun

Burghaun

11.081 km

Wadah laut

db-container20fuß

db-container20fuß

Iklan kecil

Bad Waltersdorf

Bad Waltersdorf

10.682 km

Meja angkat pemotong kaca

Hegla

Hegla

Iklan kecil

Herzogenrath

Herzogenrath

11.328 km

Mesin bor kaca

SchramlTop Clear 13 Special- 4

SchramlTop Clear 13 Special- 4

Iklan kecil

Władysławowo

Władysławowo

10.389 km

Poland

DIP TECHGlassJet NOVO

DIP TECHGlassJet NOVO

Iklan kecil

Butzbach

Butzbach

11.159 km

Pusat mesin

Starrag-HeckertHEC400D

Starrag-HeckertHEC400D

Iklan kecil

Lleida

Lleida

11.994 km

Instalasi pelapisan bubuk horizontal

WagnerHorizontal Painting line

WagnerHorizontal Painting line

Iklan Anda telah berhasil dihapus

Terjadi kesalahan