Lini pengisian lengkap bekas untuk wine tanpa karbonasi - 8000 botol per jamAPE Impianti

Lini pengisian lengkap bekas untuk wine tanpa karbonasi - 8000 botol per jam

APE Impianti

Kondisi

Bekas

Lokasi

Italia

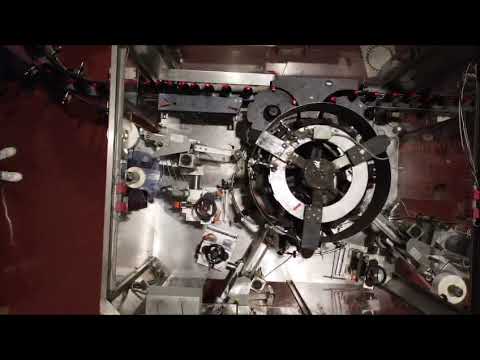

Gambar menunjukkan

Tampilkan peta

Data mesin

Harga & Lokasi

- Lokasi:

- , Italia

Hubungi

Rincian penawaran

- ID iklan:

- A21193520

- Nomor referensi:

- LC597

- Pembaruan:

- terakhir pada 09.02.2026

Deskripsi

Technical Specifications & Performance Data

This pre-owned bottling line is engineered for dependable beverage production and downstream industrial packaging at up to 8,000 bottles per hour. The configuration integrates APE Impianti carton handling with KOSME labelling technology and delivers robust operation for second-hand applications, as well as flexible format control typical for glass and PET bottles.

Production speed: 8,000 bottles per hour

Dkjdsyh E Huepfx Abhsh

Compatible formats: Standard carton pack format includes 12 x 0.75 L; additional formats manageable with change parts

Containers: Designed for bottle handling; configuration suitable for PET and glass (cylindrical containers)

Labelling systems: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (divider inserter)

Electrical (labeller): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weight (labeller): 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-certified components

Advanced Automation & Control Systems

The line employs modular automation across labelling and carton handling stations to ensure consistent throughput. Operator-friendly controls at each module support fast start-up and format changeovers. The KOSME labellers feature standard European electrical specifications (400 V, 50 Hz) and coordinated installed power, guaranteeing precise label placement at line speed. APE Impianti packaging modules provide synchronized movement sequences and interlocked safety guards for downstream processes.

Integrated start/stop logic and line buffering to stabilize flow

Rapid mechanical adjustments for format changes with guided setup procedures

Interlocked safety fencing and emergency stop at main machines

Clear HMI/operator panels per machine for format selection and diagnostics

Line Integration Capabilities

This production line is designed for in-line operation with conveyors and buffering to achieve the 8,000 bottles per hour target. The dual labelling architecture—cold glue and self-adhesive—supports a wide range of label materials and presentation standards. Carton erecting, divider inserting, and packaging are fully integrated for efficient end-of-line handling, delivering consistent carton quality for logistics and warehousing.

Inline configuration compatible with upstream/downstream equipment

Cold glue and self-adhesive labelling flexibility for front/back and wrap-around applications

Carton erecting, divider inserting and packaging for 12 x 0.75 L formats

Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

This is a used filling and packaging solution with components from the construction years...

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

This pre-owned bottling line is engineered for dependable beverage production and downstream industrial packaging at up to 8,000 bottles per hour. The configuration integrates APE Impianti carton handling with KOSME labelling technology and delivers robust operation for second-hand applications, as well as flexible format control typical for glass and PET bottles.

Production speed: 8,000 bottles per hour

Dkjdsyh E Huepfx Abhsh

Compatible formats: Standard carton pack format includes 12 x 0.75 L; additional formats manageable with change parts

Containers: Designed for bottle handling; configuration suitable for PET and glass (cylindrical containers)

Labelling systems: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (divider inserter)

Electrical (labeller): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weight (labeller): 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-certified components

Advanced Automation & Control Systems

The line employs modular automation across labelling and carton handling stations to ensure consistent throughput. Operator-friendly controls at each module support fast start-up and format changeovers. The KOSME labellers feature standard European electrical specifications (400 V, 50 Hz) and coordinated installed power, guaranteeing precise label placement at line speed. APE Impianti packaging modules provide synchronized movement sequences and interlocked safety guards for downstream processes.

Integrated start/stop logic and line buffering to stabilize flow

Rapid mechanical adjustments for format changes with guided setup procedures

Interlocked safety fencing and emergency stop at main machines

Clear HMI/operator panels per machine for format selection and diagnostics

Line Integration Capabilities

This production line is designed for in-line operation with conveyors and buffering to achieve the 8,000 bottles per hour target. The dual labelling architecture—cold glue and self-adhesive—supports a wide range of label materials and presentation standards. Carton erecting, divider inserting, and packaging are fully integrated for efficient end-of-line handling, delivering consistent carton quality for logistics and warehousing.

Inline configuration compatible with upstream/downstream equipment

Cold glue and self-adhesive labelling flexibility for front/back and wrap-around applications

Carton erecting, divider inserting and packaging for 12 x 0.75 L formats

Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

This is a used filling and packaging solution with components from the construction years...

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Dokumen

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2021

Kirim permintaan

Telepon & Faks

+39 344 0... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Pengemas Kasus

APE ImpiantiInca 2001

APE ImpiantiInca 2001

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Case Erector

APE ImpiantiForm 1200 HM

APE ImpiantiForm 1200 HM

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Pengemas Kasus

APE ImpiantiINCA 2000

APE ImpiantiINCA 2000

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Case Erector

APE ImpiantiForm 2000 HM SX

APE ImpiantiForm 2000 HM SX

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Case Erector

APE ImpiantiFORM1500 HMB

APE ImpiantiFORM1500 HMB

Iklan Anda telah berhasil dihapus

Terjadi kesalahan