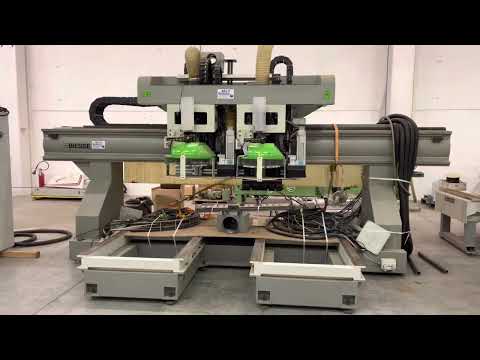

Pantograf elektronik CNCBIESSE

Arrow FT OSAI

Pantograf elektronik CNC

BIESSE

Arrow FT OSAI

tahun pembuatan

2004

Kondisi

Bekas

Lokasi

Cordignano

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Pantograf elektronik CNC

- pabrikan:

- BIESSE

- Model:

- Arrow FT OSAI

- tahun pembuatan:

- 2004

- Kondisi:

- belum diuji (bekas)

Harga & Lokasi

- Lokasi:

- Via Strada Maestra D'Italia, 31016 Cordignano TV, Italia

Hubungi

Rincian penawaran

- ID iklan:

- A6859336

- pembaruan:

- terakhir pada 29.12.2024

Deskripsi

Working area and axis travel

No. 2 worktables measuring 1,600 x 1,800 mm each

Total working area with joined tables: 3,220 x 1,800 mm

Axis travel:

X = 4,300 mm ; Y/W = 3,200 mm ; Z = 300 mm

Z clearance: 300 mm

Vacuum pumps: Becker rotary type, No. 2 x 250 m3/h

Mechanical structure in monolithic steel with fixed gantry design, including welded and thermally stabilized base, lateral beams, and upper beam as a single piece.

The upper beam has a large section (400 x 400 mm), designed with combined sections for maximum rigidity.

Osai numerical control system with DUAL TFT MONITOR

OSAI Series 10/510 DIGITAL INDUSTRIAL control with integrated second computer:

WINLINK with TeleService

Industrial PC integrated in the OSAI control system.

Interactive operator panel

Color TFT monitor dedicated to the OSAI CNC section

Color TFT monitor dedicated to the Windows PC section

No. 2 Electrospindles:

HSD Routing Milling spindles with right and left rotation

Max speed: 32,000 RPM

Special high-speed ISO 30 tool holder

Power:

10.5 kW (14.5 HP) at 18,000 RPM

10.5 kW (14.5 HP) at 24,000 RPM

7.0 kW (9.5 HP) at 32,000 RPM

Front ceramic bearings

Rear ceramic bearings

Liquid coolant system

Multi-position step-type suction hood controlled by CNC

Electrospindle floating device

Digital electronic inverter

No. 01 Axis Setting (patented system)

Consists of an additional independent Z-axis for operating head No. 2 (on the left).

Allows Z-axis compensation via CNC for tool length differences on the same piece.

Enables machining operations requiring mechanical piece copying in floating mode.

No. 2 Carousel Tool Magazines with 10 positions each for fast and efficient tool changes

Nwedpfxehvmwke Ab Nsn

No. 2 HSD Drilling Heads

BH 19 type with 19 drill spindles:

13 independent vertical spindles arranged in a T:

5 on X-axis with 32 mm pitch

8 on Y-axis with 32 mm pitch

4 horizontal spindles in Y direction (2+2 opposed)

2 horizontal spindles in X direction (1+1 opposed)

Installation data:

Footprint approx. 6,950 x 6,700 mm (width x depth)

Electrical supply: 380 V 3-phase, 50 Hz; I = 100 A; P = 59 kW

Pneumatic supply: 7.00 - 7.50 Bar

Extraction system: 2 x diameter 200 mm; 30 m/sec; at approx. H = 3,200 mm

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

No. 2 worktables measuring 1,600 x 1,800 mm each

Total working area with joined tables: 3,220 x 1,800 mm

Axis travel:

X = 4,300 mm ; Y/W = 3,200 mm ; Z = 300 mm

Z clearance: 300 mm

Vacuum pumps: Becker rotary type, No. 2 x 250 m3/h

Mechanical structure in monolithic steel with fixed gantry design, including welded and thermally stabilized base, lateral beams, and upper beam as a single piece.

The upper beam has a large section (400 x 400 mm), designed with combined sections for maximum rigidity.

Osai numerical control system with DUAL TFT MONITOR

OSAI Series 10/510 DIGITAL INDUSTRIAL control with integrated second computer:

WINLINK with TeleService

Industrial PC integrated in the OSAI control system.

Interactive operator panel

Color TFT monitor dedicated to the OSAI CNC section

Color TFT monitor dedicated to the Windows PC section

No. 2 Electrospindles:

HSD Routing Milling spindles with right and left rotation

Max speed: 32,000 RPM

Special high-speed ISO 30 tool holder

Power:

10.5 kW (14.5 HP) at 18,000 RPM

10.5 kW (14.5 HP) at 24,000 RPM

7.0 kW (9.5 HP) at 32,000 RPM

Front ceramic bearings

Rear ceramic bearings

Liquid coolant system

Multi-position step-type suction hood controlled by CNC

Electrospindle floating device

Digital electronic inverter

No. 01 Axis Setting (patented system)

Consists of an additional independent Z-axis for operating head No. 2 (on the left).

Allows Z-axis compensation via CNC for tool length differences on the same piece.

Enables machining operations requiring mechanical piece copying in floating mode.

No. 2 Carousel Tool Magazines with 10 positions each for fast and efficient tool changes

Nwedpfxehvmwke Ab Nsn

No. 2 HSD Drilling Heads

BH 19 type with 19 drill spindles:

13 independent vertical spindles arranged in a T:

5 on X-axis with 32 mm pitch

8 on Y-axis with 32 mm pitch

4 horizontal spindles in Y direction (2+2 opposed)

2 horizontal spindles in X direction (1+1 opposed)

Installation data:

Footprint approx. 6,950 x 6,700 mm (width x depth)

Electrical supply: 380 V 3-phase, 50 Hz; I = 100 A; P = 59 kW

Pneumatic supply: 7.00 - 7.50 Bar

Extraction system: 2 x diameter 200 mm; 30 m/sec; at approx. H = 3,200 mm

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Dokumen

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2019

Kirim permintaan

Telepon & Faks

+39 335 8... iklan

Iklan Anda telah berhasil dihapus

Terjadi kesalahan