Pengamplas sikatDANIBRUM

DAS LDX 1000 - 6

Pengamplas sikat

DANIBRUM

DAS LDX 1000 - 6

Tahun pembuatan

2025

Kondisi

Baru

Lokasi

Vermești

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Pengamplas sikat

- Pabrikan:

- DANIBRUM

- Model:

- DAS LDX 1000 - 6

- Tahun pembuatan:

- 2025

- Kondisi:

- baru

- Fungsi:

- berfungsi sepenuhnya

Harga & Lokasi

- Lokasi:

- Strada Combinatului, Bacău 605200, România

Hubungi

Rincian penawaran

- ID iklan:

- A19072501

- Pembaruan:

- terakhir pada 05.05.2025

Deskripsi

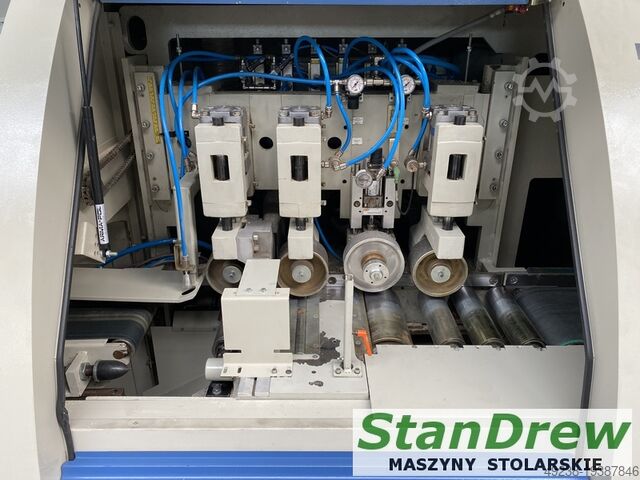

Improve surface finish quality with the DAS LDX 1000 – 6 Brush Sander

The DAS LDX 1000 – 6 automatic brush sanding machine is engineered for precise sanding and finishing of profiled wooden or MDF components, delivering excellent results even for the most demanding aesthetic requirements. It is ideal for smoothing, fine sanding, and final surface preparation, thanks to its robust and versatile configuration with six working units.

Standard equipment and technical features:

Multiple working units: Oscillating longitudinal drums, oscillating pads, and transverse drums with 280 mm diameter and 1000 mm width, fitted with 20 helically-mounted brushes.

Working capacity: Max. width 1000 mm, max. workpiece thickness 100 mm.

Efficient sanding: Disc rotation speed adjustable between 50 – 300 RPM via frequency inverter.

Sanding brushes: Adjustable length from 20 – 70 mm, allowing detailed work on profiles up to 8 mm deep.

Touchscreen control panel: Ergonomically positioned for independent control of each unit. The intuitive interface, developed by DANIBRUM engineers, enables fast and efficient operation.

High-adhesion conveyor belt: Fitted with ribbed rubber for constant feed, powered by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor, and entry/exit dust removal brushes.

Professional sliding system: Based on recirculating ball bearings for precise, reliable movement with low maintenance. Manual lubrication.

Oscillation for sanding units: Ensures uniform finishing and extends the life of abrasive belts and sisal brushes.

Efficient extraction system: Each group has dedicated extraction outlets connected to 8 x 100 mm ports, maintaining a clean and efficient working area.

Redpfx Ahjwhbtzjwep

Quick access side openings: Large side doors for easy brush change and rapid maintenance access.

Toothed belt drive: Guarantees consistent speeds, stable power transmission, and low operating noise.

Finishing flexibility: "Fast release" system enables rapid belt and brush change. The configurable setup suits various sanding and finishing styles.

The DAS LDX 1000 – 6 machine provides an efficient solution for manufacturers seeking superior quality in the processing of profiled wooden elements, delivering high productivity and flawless finishes.

Max. working width: 1000 mm

Max. working thickness: 100 mm

Diameter of longitudinal drums (Ø): 220 mm

Longitudinal drums drive motor power – oscillating: 2 x 1.5 kW

Oscillation motor power for longitudinal drums: 0.55 kW

Oscillating pad diameter: 200 mm

Oscillating pad drive motor power: 1.5 kW

Pad oscillation motor power: 0.18 kW

Transverse drum diameter (Ø): 280 mm

Transverse drum drive motor power: 2 x 2.2 kW

Feed motor power: 1.1 kW

Brush speed: max. 1000 rpm

Extraction port diameter (Ø): 4 x 100 mm

Overall dimensions: 3300 x 1600 mm

Weight: 1500 kg

Technical support available in Romanian, English, or German.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

The DAS LDX 1000 – 6 automatic brush sanding machine is engineered for precise sanding and finishing of profiled wooden or MDF components, delivering excellent results even for the most demanding aesthetic requirements. It is ideal for smoothing, fine sanding, and final surface preparation, thanks to its robust and versatile configuration with six working units.

Standard equipment and technical features:

Multiple working units: Oscillating longitudinal drums, oscillating pads, and transverse drums with 280 mm diameter and 1000 mm width, fitted with 20 helically-mounted brushes.

Working capacity: Max. width 1000 mm, max. workpiece thickness 100 mm.

Efficient sanding: Disc rotation speed adjustable between 50 – 300 RPM via frequency inverter.

Sanding brushes: Adjustable length from 20 – 70 mm, allowing detailed work on profiles up to 8 mm deep.

Touchscreen control panel: Ergonomically positioned for independent control of each unit. The intuitive interface, developed by DANIBRUM engineers, enables fast and efficient operation.

High-adhesion conveyor belt: Fitted with ribbed rubber for constant feed, powered by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor, and entry/exit dust removal brushes.

Professional sliding system: Based on recirculating ball bearings for precise, reliable movement with low maintenance. Manual lubrication.

Oscillation for sanding units: Ensures uniform finishing and extends the life of abrasive belts and sisal brushes.

Efficient extraction system: Each group has dedicated extraction outlets connected to 8 x 100 mm ports, maintaining a clean and efficient working area.

Redpfx Ahjwhbtzjwep

Quick access side openings: Large side doors for easy brush change and rapid maintenance access.

Toothed belt drive: Guarantees consistent speeds, stable power transmission, and low operating noise.

Finishing flexibility: "Fast release" system enables rapid belt and brush change. The configurable setup suits various sanding and finishing styles.

The DAS LDX 1000 – 6 machine provides an efficient solution for manufacturers seeking superior quality in the processing of profiled wooden elements, delivering high productivity and flawless finishes.

Max. working width: 1000 mm

Max. working thickness: 100 mm

Diameter of longitudinal drums (Ø): 220 mm

Longitudinal drums drive motor power – oscillating: 2 x 1.5 kW

Oscillation motor power for longitudinal drums: 0.55 kW

Oscillating pad diameter: 200 mm

Oscillating pad drive motor power: 1.5 kW

Pad oscillation motor power: 0.18 kW

Transverse drum diameter (Ø): 280 mm

Transverse drum drive motor power: 2 x 2.2 kW

Feed motor power: 1.1 kW

Brush speed: max. 1000 rpm

Extraction port diameter (Ø): 4 x 100 mm

Overall dimensions: 3300 x 1600 mm

Weight: 1500 kg

Technical support available in Romanian, English, or German.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2009

Kirim permintaan

Telepon & Faks

+40 756 3... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Strassberg

Strassberg

11.178 km

Mesin pembulatan dan penghalusan tepi

LissmacSBM-XS-300 G1E1

LissmacSBM-XS-300 G1E1

Iklan kecil

Böblingen

Böblingen

11.175 km

Mesin penggilingan meja

Holzkraftminimax t 45c Tischfräse

Holzkraftminimax t 45c Tischfräse

Iklan kecil

Scerne

Scerne

10.886 km

Gergaji panel vertikal

Putsch MeniconiUniver

Putsch MeniconiUniver

Iklan kecil

Rumania

Rumania

10.001 km

Mesin nesting CNC dengan pemuatan dan pembongkaran

NanxingNCG3021L

NanxingNCG3021L

Iklan kecil

Ludwigsstadt

Ludwigsstadt

10.974 km

Mesin deburring sikat

WeberTTS-1100

WeberTTS-1100

Iklan kecil

Egenhofen

Egenhofen

11.027 km

Mesin penyikat, mesin pengamplasan

- ItalyAdvance ROTOR 600.4 / Special 5

- ItalyAdvance ROTOR 600.4 / Special 5

Iklan kecil

Nattheim

Nattheim

11.085 km

Cat dinding ekstraksi kabut

HöckerPaint Star 3500

HöckerPaint Star 3500

Iklan kecil

Miechucino

Miechucino

10.472 km

Optimizer GreCon Dimter OPTICUT 350

WEINIGDimter Opticut 350 R

WEINIGDimter Opticut 350 R

Iklan kecil

Jerman

Jerman

11.207 km

Bürstenschleifmaschine Fladder Gyro 300 VAC M

FladderFladder Gyro 300 VAC Ex.

FladderFladder Gyro 300 VAC Ex.

Iklan kecil

Egenhofen

Egenhofen

11.027 km

Mesin penggilingan spindel putar

RoblandTi 120 E

RoblandTi 120 E

Iklan Anda telah berhasil dihapus

Terjadi kesalahan