Mesin bor lubang pasakGanner

DB 21

Mesin bor lubang pasak

Ganner

DB 21

Tahun pembuatan

2024

Kondisi

Bekas

Lokasi

Nattheim

Gambar menunjukkan

Tampilkan peta

Data mesin

Harga & Lokasi

- Lokasi:

- Daimlerstr. 21, 89564 Nattheim, DE

Hubungi

Rincian penawaran

- ID iklan:

- A20292745

- Nomor referensi:

- BD-P-24005

- Pembaruan:

- terakhir pada 23.01.2026

Deskripsi

Dowel Boring Machine GANNOMAT 'DB 21400V', 3Ph, 50Hz / 1.5 kW, fully equipped in standard configuration with:

- Fully automatic electronic control with pulse operation via foot valve: clamping – drilling – releasing, plus electrical skip cycle function.

- Automatic return of the drilling unit after reaching the preset drilling depth.

- Automatic extension of drilling depth when drilling from the edge. This eliminates the need to adjust the drilling depth when switching from face to edge drilling (+10 mm, e.g. for dowel length 35 mm, face drilling depth 14 mm and edge drilling depth 24 mm).

- 1 drilling beam with 21 spindles, 32 mm pitch, motor 1.5 kW (feed 0–70 mm), incl. 21 quick-change chucks (Ganner system) for easy bit change.

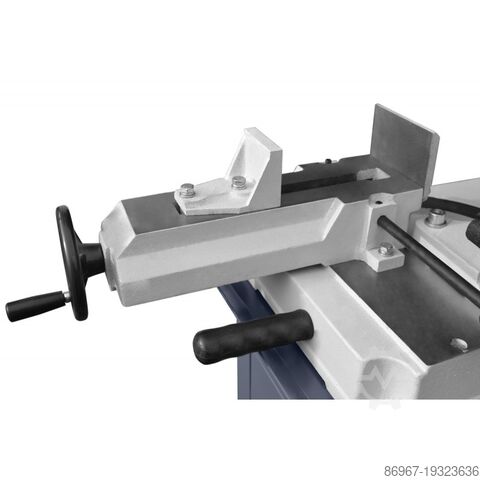

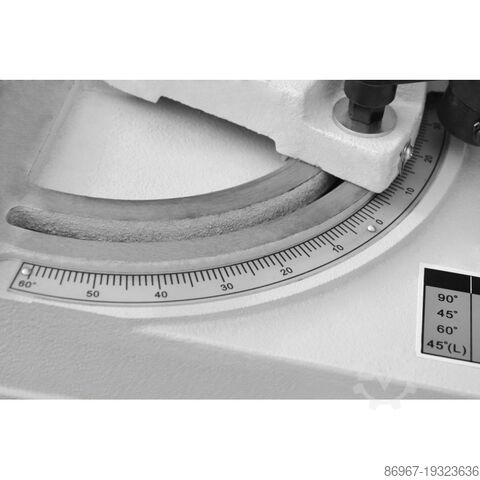

- Simple swivel motion of the drilling unit from 0° to 90° supported by gas cylinder.

- 1 clamp carrier, movable along the Y-axis, with 3 pneumatic clamps for workpiece height up to max. 80 mm.

Ideal stop system including:

- 1 stop rail, 1800 mm, for shelf drilling (aluminum profile 40x40 mm) with 3 flip stops,

- Quick-change system, easily switchable from right to left stops for mirror-image drilling of shelves in carcass construction; also suitable for line boring in 32 mm system.

- Side stops and position adjustments, as well as drilling height positioning over the support table with mechanical digital counters.

- Side stops can be easily swung away for quick conversion between carcass, frame, and line boring.

- Clamping arms for clamp carrier suitable for line boring positions up to max. 300 mm.

- Ideal three-stage tool system.

- 1 set of dowel drill bits:

- 5 carbide dowel drill bits, Ø 8x77 mm, right

- 4 carbide dowel drill bits, Ø 8x77 mm, left

Basic machine Dowel Boring Machine GANNOMAT 'DB 21400V', 3Ph, 50Hz / 1.5 kW completely in standard version with:

- Fully automatic electronic control with pulse operation via foot valve for clamping – drilling – releasing, with electrical skip cycle.

- Automatic return of the drilling unit after reaching the preset drilling depth.

- Automatic drilling depth extension for edge drilling (as above).

- 1 drilling beam with 21 spindles, 32 mm pitch, motor 1.5 kW (feed 0–70 mm), incl. 21 quick-change chucks (Ganner system).

- Simple swivel of the drilling unit from 0° to 90° supported by gas cylinder.

- 1 clamp carrier movable on Y-axis with 3 pneumatic cylinders for workpiece up to max. 80 mm height.

- Ideal stop system as above (1800 mm stop rail, 40x40 mm aluminum profile, 3 flip stops, quick change from right to left for mirrored shelf drilling; also usable for 32 mm system line boring).

- Side stops and position adjustments, and drilling height setting above the support table via mechanical digital counters.

- Side stops easily swiveling away for fast changeover between carcass, frame, and line boring.

- Clamping arms on clamp carrier for row positions up to max. 300 mm.

- Ideally structured three-stage tool system.

- Extraction funnel, dust-tested, ø 120 mm

Kedpfxexnlflo Aglewt

- 1 set for line boring in 32 mm system

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

- Fully automatic electronic control with pulse operation via foot valve: clamping – drilling – releasing, plus electrical skip cycle function.

- Automatic return of the drilling unit after reaching the preset drilling depth.

- Automatic extension of drilling depth when drilling from the edge. This eliminates the need to adjust the drilling depth when switching from face to edge drilling (+10 mm, e.g. for dowel length 35 mm, face drilling depth 14 mm and edge drilling depth 24 mm).

- 1 drilling beam with 21 spindles, 32 mm pitch, motor 1.5 kW (feed 0–70 mm), incl. 21 quick-change chucks (Ganner system) for easy bit change.

- Simple swivel motion of the drilling unit from 0° to 90° supported by gas cylinder.

- 1 clamp carrier, movable along the Y-axis, with 3 pneumatic clamps for workpiece height up to max. 80 mm.

Ideal stop system including:

- 1 stop rail, 1800 mm, for shelf drilling (aluminum profile 40x40 mm) with 3 flip stops,

- Quick-change system, easily switchable from right to left stops for mirror-image drilling of shelves in carcass construction; also suitable for line boring in 32 mm system.

- Side stops and position adjustments, as well as drilling height positioning over the support table with mechanical digital counters.

- Side stops can be easily swung away for quick conversion between carcass, frame, and line boring.

- Clamping arms for clamp carrier suitable for line boring positions up to max. 300 mm.

- Ideal three-stage tool system.

- 1 set of dowel drill bits:

- 5 carbide dowel drill bits, Ø 8x77 mm, right

- 4 carbide dowel drill bits, Ø 8x77 mm, left

Basic machine Dowel Boring Machine GANNOMAT 'DB 21400V', 3Ph, 50Hz / 1.5 kW completely in standard version with:

- Fully automatic electronic control with pulse operation via foot valve for clamping – drilling – releasing, with electrical skip cycle.

- Automatic return of the drilling unit after reaching the preset drilling depth.

- Automatic drilling depth extension for edge drilling (as above).

- 1 drilling beam with 21 spindles, 32 mm pitch, motor 1.5 kW (feed 0–70 mm), incl. 21 quick-change chucks (Ganner system).

- Simple swivel of the drilling unit from 0° to 90° supported by gas cylinder.

- 1 clamp carrier movable on Y-axis with 3 pneumatic cylinders for workpiece up to max. 80 mm height.

- Ideal stop system as above (1800 mm stop rail, 40x40 mm aluminum profile, 3 flip stops, quick change from right to left for mirrored shelf drilling; also usable for 32 mm system line boring).

- Side stops and position adjustments, and drilling height setting above the support table via mechanical digital counters.

- Side stops easily swiveling away for fast changeover between carcass, frame, and line boring.

- Clamping arms on clamp carrier for row positions up to max. 300 mm.

- Ideally structured three-stage tool system.

- Extraction funnel, dust-tested, ø 120 mm

Kedpfxexnlflo Aglewt

- 1 set for line boring in 32 mm system

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2010

Kirim permintaan

Telepon & Faks

+49 7321 ... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Siedlce

Siedlce

10.199 km

Gergaji pita

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Iklan kecil

Siedlce

Siedlce

10.199 km

Planer-penghalus ketebalan

CORMAKPT250 230V

CORMAKPT250 230V

Iklan kecil

Bad Sooden-Allendorf

Bad Sooden-Allendorf

11.053 km

Mesin dowel

ScheerDB 150

ScheerDB 150

Iklan kecil

Juszczyn

Juszczyn

10.388 km

Mesin bor multi-spindel

MaggiBoring System 35

MaggiBoring System 35

Iklan kecil

Certaldo

Certaldo

11.117 km

Mesin bor multi-spindel

Maggi EngineeringBoring System 800 GT

Maggi EngineeringBoring System 800 GT

Iklan kecil

Nordhorn

Nordhorn

11.217 km

Penutup lantai papan chip Papan platform penyimpanan

4.000 m², 3.200 mm x 1.000 mm x 38 mmAusführung: P6

4.000 m², 3.200 mm x 1.000 mm x 38 mmAusführung: P6

Iklan kecil

Berlin

Berlin

10.798 km

Perlindungan lengkap dan keamanan yang lebih tinggi.

Bodori5 3000W

Bodori5 3000W

Iklan kecil

Bad Sooden-Allendorf

Bad Sooden-Allendorf

11.053 km

Mesin pengikat tepi

BMS - BlaichKantenfix B2

BMS - BlaichKantenfix B2

Iklan kecil

Wijchen

Wijchen

11.326 km

Mesin Press Briket Schuko Compacto CT 700 S-20 2017

SchukoCompacto CT 700 S-20

SchukoCompacto CT 700 S-20

Iklan kecil

Siedlce

Siedlce

10.199 km

Penggiling tepi

CORMAKMM2315Q 400/230V

CORMAKMM2315Q 400/230V

Iklan Anda telah berhasil dihapus

Terjadi kesalahan