Pengepres betonHidralmac

150 Tonnen Betonpresse

Pengepres beton

Hidralmac

150 Tonnen Betonpresse

Tahun pembuatan

2017

Kondisi

Baru

Lokasi

Ennepetal

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Pengepres beton

- Pabrikan:

- Hidralmac

- Model:

- 150 Tonnen Betonpresse

- Nomor mesin:

- DF0149

- Tahun pembuatan:

- 2017

- Kondisi:

- baru

Harga & Lokasi

- Lokasi:

- Scharpenberger Str. 96-98, 58256 Ennepetal, Deutschland

Hubungi

Rincian penawaran

- ID iklan:

- A3871212

- Nomor referensi:

- 1358-NEBR-1215

- Pembaruan:

- terakhir pada 27.03.2025

Deskripsi

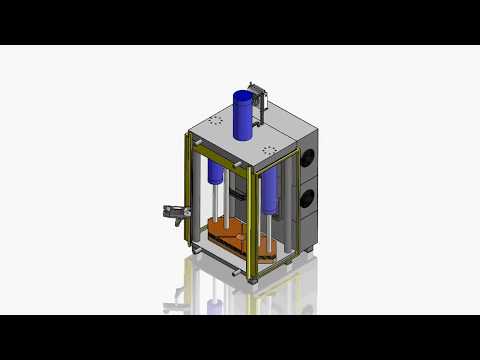

Pressure: 2x 75 / 150 t

Clear passage width: 2050 x 965 mm

Stroke: 800 mm

Total power requirement: main motor 22 kW

Ledpfod Aftpsx Aglerg

Machine weight approx.: 6.5 t

Space requirement approx.: 1500 x 1025 mm

Lower ram: 150 mm

Upper ram: 150 mm

Base plate (steel): 72 mm

Additional motors and consumers: 2 kW

Ram size, upper ram approx.: 870 x 350 x 150 mm

Ram size, lower ram approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide column diameter: 120 mm

Piston diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Travel path of both lifting cylinders and the pressure cylinder each: 350 mm

Max. open height: 1600 mm

Pressing speed: 15-0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via contactless sensors: 0.5 mm

The press is equipped with two column guides, each 120 mm in diameter, guiding both the lower and upper rams. The guides are made of bronze.

The lower ram features a robust design with a thickness of 150 mm.

The upper ram is also equipped with a 150 mm thick steel plate.

The machine's base plate is made of 72 mm thick steel, providing tilt-stability during transport. For this reason, the oil tank with the hydraulic system is also mounted near the base.

Both hydraulics and electronics are permanently integrated into the machine and protected from contamination by an enclosure.

To dissipate the resulting heat, the machine is fitted with an oil cooler mounted on top of the press. The control cabinet is also air-cooled.

For potential future maintenance of the hydraulics, the press's rear interior wall can be easily removed.

The two-hand control is securely fixed to facilitate transport but remains movable via a joint.

High-resolution light barriers prevent entry of personnel into the hazardous area.

To ensure comfortable operation, the machine is equipped on both sides with transparent acrylic windows, 6 mm thick, which may be replaced with new panels after several years of use, though this incurs minimal cost.

Additionally, the press features four high-power LED lights integrated into the upper plate.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Clear passage width: 2050 x 965 mm

Stroke: 800 mm

Total power requirement: main motor 22 kW

Ledpfod Aftpsx Aglerg

Machine weight approx.: 6.5 t

Space requirement approx.: 1500 x 1025 mm

Lower ram: 150 mm

Upper ram: 150 mm

Base plate (steel): 72 mm

Additional motors and consumers: 2 kW

Ram size, upper ram approx.: 870 x 350 x 150 mm

Ram size, lower ram approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide column diameter: 120 mm

Piston diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Travel path of both lifting cylinders and the pressure cylinder each: 350 mm

Max. open height: 1600 mm

Pressing speed: 15-0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via contactless sensors: 0.5 mm

The press is equipped with two column guides, each 120 mm in diameter, guiding both the lower and upper rams. The guides are made of bronze.

The lower ram features a robust design with a thickness of 150 mm.

The upper ram is also equipped with a 150 mm thick steel plate.

The machine's base plate is made of 72 mm thick steel, providing tilt-stability during transport. For this reason, the oil tank with the hydraulic system is also mounted near the base.

Both hydraulics and electronics are permanently integrated into the machine and protected from contamination by an enclosure.

To dissipate the resulting heat, the machine is fitted with an oil cooler mounted on top of the press. The control cabinet is also air-cooled.

For potential future maintenance of the hydraulics, the press's rear interior wall can be easily removed.

The two-hand control is securely fixed to facilitate transport but remains movable via a joint.

High-resolution light barriers prevent entry of personnel into the hazardous area.

To ensure comfortable operation, the machine is equipped on both sides with transparent acrylic windows, 6 mm thick, which may be replaced with new panels after several years of use, though this incurs minimal cost.

Additionally, the press features four high-power LED lights integrated into the upper plate.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2018

Kirim permintaan

Telepon & Faks

+49 209 9... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Hessisch Lichtenau

Hessisch Lichtenau

11.072 km

Mesin finishing melalui getaran melingkar

WALTHER TROWALCLS-230

WALTHER TROWALCLS-230

Iklan kecil

Schorfheide

Schorfheide

10.775 km

Pabrik pencampuran stasioner

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Iklan kecil

Mindelheim

Mindelheim

11.078 km

Pusat mesin

Deckel MahoDMC 60U Hi-dyn

Deckel MahoDMC 60U Hi-dyn

Iklan kecil

Italia

Italia

11.016 km

Penempaan Radial Panas yang dirombak sepenuhnya

CNC GFMSX-13

CNC GFMSX-13

Iklan kecil

Hochdorf

Hochdorf

11.141 km

Unit Pendingin Suhu (TCU) / Chiller

SingleChill Plus Testing CHT-130

SingleChill Plus Testing CHT-130

Iklan kecil

Oftersheim

Oftersheim

11.190 km

Paket daya hidrolik

Parker

Parker

Iklan kecil

Ciriè

Ciriè

11.352 km

Mesin press hidrolik kolom ganda

EMANUELDEA 400/2000

EMANUELDEA 400/2000

Iklan kecil

Fuldatal

Fuldatal

11.080 km

Siklus dikontrol mesin bubut

Weisser HeinbronnHECKTOR CNC 295x2000

Weisser HeinbronnHECKTOR CNC 295x2000

Iklan kecil

Wiefelstede

Wiefelstede

11.134 km

Agregat hidrolik 5,5 kW / 1455 U / menit

H+LDK52 1-6-250P-391K

H+LDK52 1-6-250P-391K

Iklan kecil

Jerman

Jerman

11.023 km

Pusat pembubutan dan penggilingan CNC

Niles-SimmonsN30/2500 MC

Niles-SimmonsN30/2500 MC

Iklan Anda telah berhasil dihapus

Terjadi kesalahan