Mesin uji roda gigiKLINGELNBERG

PFSU 1600

Mesin uji roda gigi

KLINGELNBERG

PFSU 1600

Tahun pembuatan

1975

Kondisi

Bekas

Lokasi

Metzingen

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Mesin uji roda gigi

- Pabrikan:

- KLINGELNBERG

- Model:

- PFSU 1600

- Tahun pembuatan:

- 1975

- Kondisi:

- bekas

Harga & Lokasi

- Lokasi:

- Metzingen

Hubungi

Rincian penawaran

- ID iklan:

- A16566671

- Nomor referensi:

- 1049-422129

- Pembaruan:

- terakhir pada 18.07.2024

Deskripsi

Wheel diameter – max. 160 – 1,600 mm

Wheel width 250 mm

Module – max. 20

Module – min. 1.5

Total power requirement 1 kW

Machine weight approx. 3 t

Space requirement approx. m

K L I N G E L N B E R G

Universal Gear Testing Machine for Involute and

Lead Inspection Type PFSU 1600

Year of manufacture: 1975, modernized in 1995 #B 2281

Working range:

Min./Max. gear diameter: 160 – 1,600 mm

Module range: 1.5 – 20 mm

Max. gear width: 250 mm

Stroke of measuring slide approx.: 300 mm

Max. helix angle: 0 – 90°

Max. workpiece length in centers: approx. 1,150 mm

Tailstock throat: 450 mm

Diagram recording magnification: 50/250/500/1000 x

Max. test gear weight: approx. 4,000 kg

Weight approx.: 3,000 kg

Total drive approx. 1 kW – 380 V – 50 Hz

Itsdpfxjt Hwpts Aa Nsb

Suitable for inspecting:

- Tooth profile (involute)

- Tooth lead (helix angle/lead) on internal and external gears, cutting and shaving gears, worms, etc.

- Tooth runout, surface roughness

- Determining/reconstructing base circle and helix angle, and more

Accessories / Special equipment:

- Optical base circle setting and optical angle adjustment; no base circle disks required

- Designed to accept heavy workpieces; testing cycle can be motorized or manually controlled via handwheels

- Rotating auxiliary table, Ø 480 mm, for mounting larger gear bodies, with 2 sets of different-length supports (400 and 470 mm), up to the maximum gear diameter of 1,600 mm

- Counter-support AV 17 for maximum workpiece length of 1,150 mm

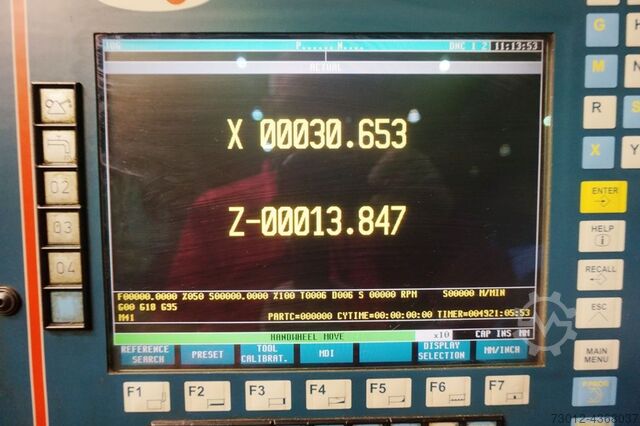

- Separate electrical cabinet for manual movement control

- GFM Computer Type ZMP 20 e with software for automatic gear measurement, updated in English and optionally German, program update to latest version V 21.17, ideal for generating modern test reports with graphics, graphic display on monitor, additional subprograms, HP printer, flat screen

- Various probe inserts, small parts, adjustable mount for indexing test device (mounted at rear), leveling feet, etc.

- Without indexing test device, but mounting provided and installed at rear

Condition: very good – demonstration-ready, professionally dismantled and reinstalled.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Wheel width 250 mm

Module – max. 20

Module – min. 1.5

Total power requirement 1 kW

Machine weight approx. 3 t

Space requirement approx. m

K L I N G E L N B E R G

Universal Gear Testing Machine for Involute and

Lead Inspection Type PFSU 1600

Year of manufacture: 1975, modernized in 1995 #B 2281

Working range:

Min./Max. gear diameter: 160 – 1,600 mm

Module range: 1.5 – 20 mm

Max. gear width: 250 mm

Stroke of measuring slide approx.: 300 mm

Max. helix angle: 0 – 90°

Max. workpiece length in centers: approx. 1,150 mm

Tailstock throat: 450 mm

Diagram recording magnification: 50/250/500/1000 x

Max. test gear weight: approx. 4,000 kg

Weight approx.: 3,000 kg

Total drive approx. 1 kW – 380 V – 50 Hz

Itsdpfxjt Hwpts Aa Nsb

Suitable for inspecting:

- Tooth profile (involute)

- Tooth lead (helix angle/lead) on internal and external gears, cutting and shaving gears, worms, etc.

- Tooth runout, surface roughness

- Determining/reconstructing base circle and helix angle, and more

Accessories / Special equipment:

- Optical base circle setting and optical angle adjustment; no base circle disks required

- Designed to accept heavy workpieces; testing cycle can be motorized or manually controlled via handwheels

- Rotating auxiliary table, Ø 480 mm, for mounting larger gear bodies, with 2 sets of different-length supports (400 and 470 mm), up to the maximum gear diameter of 1,600 mm

- Counter-support AV 17 for maximum workpiece length of 1,150 mm

- Separate electrical cabinet for manual movement control

- GFM Computer Type ZMP 20 e with software for automatic gear measurement, updated in English and optionally German, program update to latest version V 21.17, ideal for generating modern test reports with graphics, graphic display on monitor, additional subprograms, HP printer, flat screen

- Various probe inserts, small parts, adjustable mount for indexing test device (mounted at rear), leveling feet, etc.

- Without indexing test device, but mounting provided and installed at rear

Condition: very good – demonstration-ready, professionally dismantled and reinstalled.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Kirim permintaan

Telepon & Faks

+49 7123 ... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Kanada

Kanada

12.543 km

Mesin pengukur roda gigi

KLINGELNBERG-OERLIKONCS 200

KLINGELNBERG-OERLIKONCS 200

Iklan kecil

Hilden

Hilden

11.263 km

Mesin uji roda gigi bevel

KLINGELNBERG-OERLIKONT60 A

KLINGELNBERG-OERLIKONT60 A

Iklan kecil

Grüsch

Grüsch

11.156 km

Mesin penggiling roda gigi bevel

KLINGELNBERGG 27

KLINGELNBERGG 27

Iklan kecil

Dreieich

Dreieich

11.168 km

Menggerek mesin-Internal - vertikal

CARDINAL

CARDINAL

Iklan kecil

Crespellano

Crespellano

11.089 km

Mesin penggiling gigi

NilesZSTZ 10L

NilesZSTZ 10L

Iklan kecil

Tönisvorst

Tönisvorst

11.291 km

Mesin hobbing gigi - vertikal

PFAUTERP 1503/1800 B

PFAUTERP 1503/1800 B

Iklan kecil

Fuente de Cantos

Fuente de Cantos

12.670 km

Mesin Pembentuk Gear

DEMMOF7280

DEMMOF7280

Iklan kecil

București

București

9.907 km

Generator Roda Heliks MDV 2000

1 MAI PLOIESTIMDV 2000

1 MAI PLOIESTIMDV 2000

Iklan kecil

Haiger

Haiger

11.185 km

Mesin CNC bubut

PinachoCobra 180

PinachoCobra 180

Iklan kecil

Metzingen

Metzingen

11.157 km

Mesin pembentuk gigi

LORENZLS 400

LORENZLS 400

Iklan Anda telah berhasil dihapus

Terjadi kesalahan