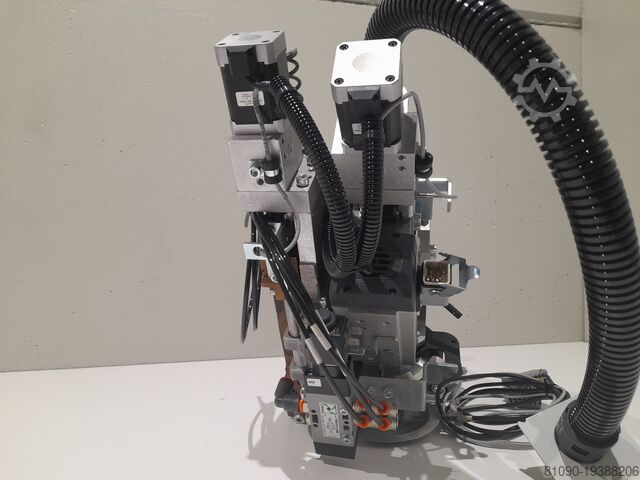

Beli Biesse Akron 845 bekas (333)

Pollenzo

Pollenzo MESIN Y90L

BIESSEY616109092

Pollenzo

Pollenzo UJI.SPINDEL KHUSUS 7 LANGKAH 4 LANGKAH 57

BIESSE

Pollenzo

Pollenzo UJI. MANDR KHUSUS7. LULUS LAMPIRAN TENGAH57

BIESSE

+44 20 806 810 84

Pollenzo

Pollenzo TANG 130X130 T=85

BIESSE

Pollenzo

Pollenzo KEPALA KIRI 7 POIN

BIESSE

Temukan lebih banyak mesin bekas

Pollenzo

Pollenzo MODUL HSD PE 106

BIESSE

Pollenzo

Pollenzo MOD.PE222 GTD06

BIESSE

Pollenzo

Pollenzo KEPALA LENGKAP 4 SPINDEL

BIESSE

Pollenzo

Pollenzo KEPALA PENGEBORAN BIESSE 6 SPINDLE

BIESSE

Pollenzo

Pollenzo UJI. LAMPIRAN SPINDEL KHUSUS 4 LANGKAH 2 57

BIESSE

Pollenzo

Pollenzo Kelompok pengupas atas

BIESSE

Pollenzo

Pollenzo KEPALA 3 TITIK MC

BIESSE

Pollenzo

Pollenzo MOD.PE302A 8 KELUAR

BIESSE

Pollenzo

Pollenzo MOD.PE302A 8 KELUAR

BIESSE

Pollenzo

Pollenzo MOD.PE323A

BIESSE

Pollenzo

Pollenzo MOD.PE222 GTD06

BIESSE

Pollenzo

Pollenzo CANGKIR PENGISAP KENDUR. 131,5X75X48

BIESSE

Pollenzo

Pollenzo MOT. SM137 R=1:8

BIESSE

Pollenzo

Pollenzo UJI. 6 SPINDEL KHUSUS LAMPIRAN 3 LANGKAH 57

BIESSE

Pollenzo

Pollenzo Edgebander

BIESSE

Pollenzo

Pollenzo KEPALA LENGKAP 3 SPINDEL PUSAT S

biesse

Pollenzo

Pollenzo KEPALA KLEM R25

BIESSE

Pollenzo

Pollenzo 6 POIN TETINA

BIESSE

Pollenzo

Pollenzo UJI. KHUSUS3 MANDR. PAS SERANGAN PUSAT 57

BIESSE

Pollenzo

Pollenzo 5-MANDR. SALURAN KONEKSI PUSAT KEPALA PAS57

BIESSE

Bekas Biesse Akron 845 (333)

Sekarang telusuri seluruh Machineseeker dengan lebih dari 200.000 mesin bekas.Jelajahi nama mesin paling populer:

+44 20 806 810 84