Wendetischkombination für HolzrahmenbauRandek AB

BS20

Wendetischkombination für Holzrahmenbau

Randek AB

BS20

Tahun pembuatan

2026

Kondisi

Baru

Lokasi

Falkenberg

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Wendetischkombination für Holzrahmenbau

- Pabrikan:

- Randek AB

- Model:

- BS20

- Tahun pembuatan:

- 2026

- Kondisi:

- baru

Harga & Lokasi

- Lokasi:

- Falkenberg, Schweden

Hubungi

Rincian penawaran

- ID iklan:

- A896820

- Nomor referensi:

- BS20

- Pembaruan:

- terakhir pada 22.01.2026

Deskripsi

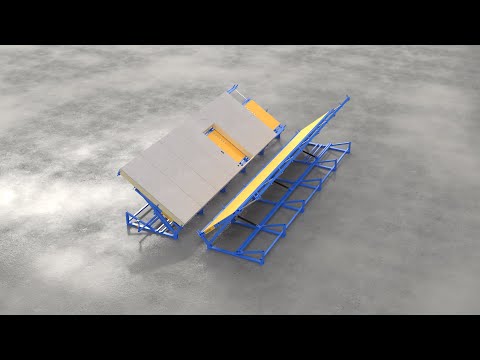

Wendetable Combination for Timber Frame Construction – BS20

The Randek Wendetable Combination is an efficient tool for producing prefabricated walls, roofs, floors, and gable constructions with timber or metal frames. The tables can be operated as standalone units or integrated into production lines. Perfectly rectangular components of high quality are achieved through the clamping function. The raising and turning of building elements is carried out via a controlled, manually operated process. The Wendetable Combination has been developed for manufacturing prefabricated houses, ensuring high productivity.

The adjustable range for component height is 2.25 m to 3.10 m. The following table lengths are available: 6.0 m / 7.5 m / 9.0 m / 12.0 m. Wall thickness can vary between 80 and 250 mm.

Functions:

The Wendetable Combination was designed for efficient execution of the following operations: manufacture of framework, insertion of insulation, stapling of plastic or paper membranes, and application and nailing of wall claddings.

• Manufacture of rectangular components: The pneumatic clamping mechanism on the long side of the master table presses the frame construction into a right-angled, high-precision component

• Automatic turning of the component, manually controlled

• Automatic raising of the component

Nsdpj Nn Hyjfx Aglskt

Technical Description:

• Length options: 6.0 m / 7.5 m / 9.0 m / 12.0 m

• Width adjustment between 2250 – 3100 mm; width can be easily set manually

• The master table can be hydraulically tilted up to 92°, the take-off table up to 86°

• Pneumatically operated pressing function on the long side of the master table

• Stops 160 mm high

• Both tables are equipped, as far as technically possible, with plywood cladding. The plywood surface enables direct placement of sub-components and beams on the table

• Table surfaces are supported by a solid steel frame

• Optimal working height of 620 mm

• Longitudinal C-sections for positioning stops for studs

• The tables are supplied fully pre-assembled. The assembly process is straightforward

Safety:

• Emergency stop switch at the control panel

• CE conformity

Advantages:

• Right-angled components thanks to the pressing function

• Controlled automatic raising and turning of components

• Ideal working height

• Flexible width adjustment

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

The Randek Wendetable Combination is an efficient tool for producing prefabricated walls, roofs, floors, and gable constructions with timber or metal frames. The tables can be operated as standalone units or integrated into production lines. Perfectly rectangular components of high quality are achieved through the clamping function. The raising and turning of building elements is carried out via a controlled, manually operated process. The Wendetable Combination has been developed for manufacturing prefabricated houses, ensuring high productivity.

The adjustable range for component height is 2.25 m to 3.10 m. The following table lengths are available: 6.0 m / 7.5 m / 9.0 m / 12.0 m. Wall thickness can vary between 80 and 250 mm.

Functions:

The Wendetable Combination was designed for efficient execution of the following operations: manufacture of framework, insertion of insulation, stapling of plastic or paper membranes, and application and nailing of wall claddings.

• Manufacture of rectangular components: The pneumatic clamping mechanism on the long side of the master table presses the frame construction into a right-angled, high-precision component

• Automatic turning of the component, manually controlled

• Automatic raising of the component

Nsdpj Nn Hyjfx Aglskt

Technical Description:

• Length options: 6.0 m / 7.5 m / 9.0 m / 12.0 m

• Width adjustment between 2250 – 3100 mm; width can be easily set manually

• The master table can be hydraulically tilted up to 92°, the take-off table up to 86°

• Pneumatically operated pressing function on the long side of the master table

• Stops 160 mm high

• Both tables are equipped, as far as technically possible, with plywood cladding. The plywood surface enables direct placement of sub-components and beams on the table

• Table surfaces are supported by a solid steel frame

• Optimal working height of 620 mm

• Longitudinal C-sections for positioning stops for studs

• The tables are supplied fully pre-assembled. The assembly process is straightforward

Safety:

• Emergency stop switch at the control panel

• CE conformity

Advantages:

• Right-angled components thanks to the pressing function

• Controlled automatic raising and turning of components

• Ideal working height

• Flexible width adjustment

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Dokumen

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2011

Kirim permintaan

Telepon & Faks

+49 5721 ... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Goor

Goor

11.259 km

Mesin Penghancur Pallet Precrusher Kayu

LUMAGO D.S.C. Dutch Shredder CompanyPYTHON 1300

LUMAGO D.S.C. Dutch Shredder CompanyPYTHON 1300

Iklan kecil

Santander

Santander

12.281 km

MESIN PENGANTONGAN - ROBOT PALETISASI

INNO TECH - ABB PALLETIZERIRB M 2000

INNO TECH - ABB PALLETIZERIRB M 2000

Iklan kecil

Kotka

Kotka

9.929 km

Penggergajian lengkap (stasioner)

LINCK

LINCK

Iklan kecil

Heiligenhaus

Heiligenhaus

11.258 km

Robot industri

KUKA Industrieroboter Lineareinheiten 8mKUKA KR180 R2900 KRC4 Linearachse 8m

KUKA Industrieroboter Lineareinheiten 8mKUKA KR180 R2900 KRC4 Linearachse 8m

Iklan kecil

Zielona Góra

Zielona Góra

10.657 km

Mesin bengkel tukang kayu

BOOSTONER-02

BOOSTONER-02

Iklan kecil

Hilzingen

Hilzingen

11.210 km

Sistem lengkap garis dinding untuk konstruksi rumah

Iklan kecil

Kanzach

Kanzach

11.147 km

Garis sambungan jari paternoster kering

WEINIG

WEINIG

Iklan kecil

Cochem-Brauheck

Cochem-Brauheck

11.274 km

Gergaji bundar logam ringan / aluminium

MTIAS-800

MTIAS-800

Iklan kecil

Jerman

Jerman

10.886 km

Derek perjalanan di atas kepala - gelagar tunggal

DemagEHK 10000-21000

DemagEHK 10000-21000

Iklan kecil

Nersingen

Nersingen

11.098 km

Mekanisasi untuk produksi KVH dan BSH

HIT

HIT

Iklan Anda telah berhasil dihapus

Terjadi kesalahan