SYSTEM FÜR DIE DIGITALE BUCHPRODUKTIONTECNAU

LIBRA 800

SYSTEM FÜR DIE DIGITALE BUCHPRODUKTION

TECNAU

LIBRA 800

Tahun pembuatan

2017

Kondisi

Bekas

Lokasi

Europa

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- SYSTEM FÜR DIE DIGITALE BUCHPRODUKTION

- Pabrikan:

- TECNAU

- Model:

- LIBRA 800

- Tahun pembuatan:

- 2017

- Kondisi:

- sangat baik (bekas)

Harga & Lokasi

- Lokasi:

- Europa

Hubungi

Rincian penawaran

- ID iklan:

- A21287107

- Nomor referensi:

- 40001.26

- Pembaruan:

- terakhir pada 20.02.2026

Deskripsi

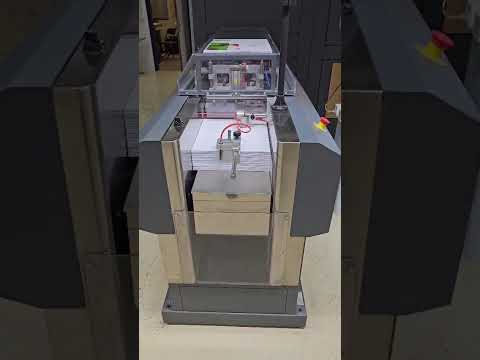

HIGHLY AUTOMATED, MODULAR SYSTEM FOR DIGITAL BOOK PRODUCTION ("BOOK ON DEMAND") AND SHORT RUNS TECNAU LIBRA 800

Intended use: Suitable for the collation and processing of small print runs and individual books ("books of one") with varying sizes, page counts, and covers.

Production capacity starting from a single copy; up to 800 copies per hour

Book format: min.: 100 x 125 mm / max.: A4

Thickness: min.: 2 mm / max.: 60 mm

Equipment / Additional Information:

Line configuration:

1. Web feeder: Unwinder, merger, Dupla cutter, and book assembly station for the production of book blocks using 2-up printing.

2. Sheet feeder: A variable number of loose sheets can be inserted into the book block as inserts. The sheets must match the size and quantity of the book block being assembled.

3. Feeding into the binding machine: Manual feeding station for pre-assembled book blocks, with transport via a reading station, book turner module, and loading robot at the binding machine.

4. Variable binding machine for producing books with softcover. The binder uses PUR glue on the spine and hot-melt adhesive on the book sides.

5. Softcover cover making unit, configured with a sheet-fed cover feeder: pre-printed cover sheets are fed in, trimmed at the front, trimmed on the sides, and scored to the correct size to match the thickness of the corresponding book block.

6. Cooling tower: Books are conveyed from the binder through the cooling tower to the three-knife trimmer.

7. Variable three-knife trimmer, suitable for trimming books in three dimensions with different types of covers.

8. System control software

Finishing line

The entire process is controlled via 2D data matrix codes. The code authorizes the system for the following automatic settings and workflow control:

• Information on book dimensions and inserts (quantity and order)

• Setup of the binding machine (spine position, thickness, and length)

• Cover preparation: Softcover → scoring, trimming, edge trimming

• Correct matching of book block and cover

Klodeylyhdopfx Ac Hsn

• Three-knife trimmer (knife positioning is automatically adjusted to book dimensions)

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Intended use: Suitable for the collation and processing of small print runs and individual books ("books of one") with varying sizes, page counts, and covers.

Production capacity starting from a single copy; up to 800 copies per hour

Book format: min.: 100 x 125 mm / max.: A4

Thickness: min.: 2 mm / max.: 60 mm

Equipment / Additional Information:

Line configuration:

1. Web feeder: Unwinder, merger, Dupla cutter, and book assembly station for the production of book blocks using 2-up printing.

2. Sheet feeder: A variable number of loose sheets can be inserted into the book block as inserts. The sheets must match the size and quantity of the book block being assembled.

3. Feeding into the binding machine: Manual feeding station for pre-assembled book blocks, with transport via a reading station, book turner module, and loading robot at the binding machine.

4. Variable binding machine for producing books with softcover. The binder uses PUR glue on the spine and hot-melt adhesive on the book sides.

5. Softcover cover making unit, configured with a sheet-fed cover feeder: pre-printed cover sheets are fed in, trimmed at the front, trimmed on the sides, and scored to the correct size to match the thickness of the corresponding book block.

6. Cooling tower: Books are conveyed from the binder through the cooling tower to the three-knife trimmer.

7. Variable three-knife trimmer, suitable for trimming books in three dimensions with different types of covers.

8. System control software

Finishing line

The entire process is controlled via 2D data matrix codes. The code authorizes the system for the following automatic settings and workflow control:

• Information on book dimensions and inserts (quantity and order)

• Setup of the binding machine (spine position, thickness, and length)

• Cover preparation: Softcover → scoring, trimming, edge trimming

• Correct matching of book block and cover

Klodeylyhdopfx Ac Hsn

• Three-knife trimmer (knife positioning is automatically adjusted to book dimensions)

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Kirim permintaan

Telepon & Faks

+41 71 54... iklan

Iklan Anda telah berhasil dihapus

Terjadi kesalahan