Tekan hidrolikHidrogarne

CF-400E/NC

Tekan hidrolik

Hidrogarne

CF-400E/NC

Kondisi

Bekas

Lokasi

Bellpuig

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Tekan hidrolik

- Pabrikan:

- Hidrogarne

- Model:

- CF-400E/NC

- Kondisi:

- hampir baru (bekas)

- Fungsi:

- berfungsi sepenuhnya

Harga & Lokasi

- Lokasi:

- Hostal Nou 2, 25250 Bellpuig, Spanien

Hubungi

Rincian teknis

- Gaya penekanan:

- 400 t

- Lebar meja:

- 2.000 mm

- Panjang meja:

- 1.000 mm

- Kecepatan operasi:

- 106 mm/dtk

- Kecepatan mundur:

- 125 mm/dtk

- Panjang langkah:

- 750 mm

- Kecepatan penekanan:

- 12 mm/dtk

- Perlengkapan:

- penghadang cahaya keselamatan

Rincian penawaran

- ID iklan:

- A19154651

- Nomor referensi:

- CF-400E/NC

- Pembaruan:

- terakhir pada 13.10.2025

Deskripsi

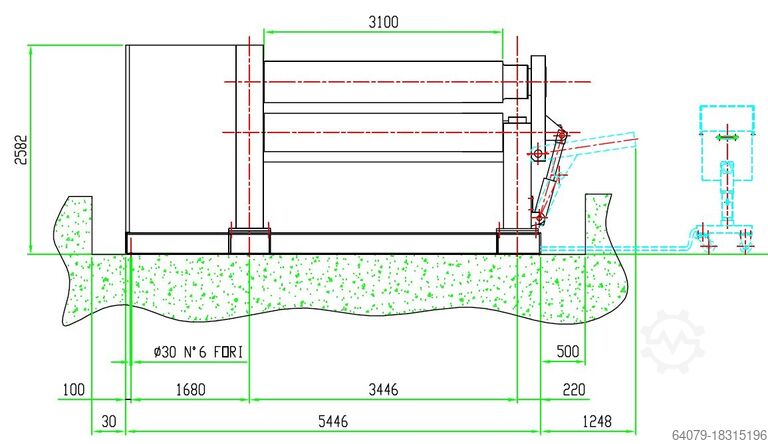

HYDRAULIC C-FRAME PRESS FOR STRAIGHTENING RAILWAY TRACKS

We are offering a new or rebuilt version of this press.

The press will be available for sale by the customer in Q2-Q3 2026, as the project timeline has been extended.

The hydraulic press CF-400E/NC is part of the CF/NC series and has been specifically developed for the straightening of railway rails.

It is equipped with an upper and lower table made from machined C45E steel with DIN 650 T-slots.

The press uses an optimized hydraulic system with a pressure of less than 255 bar, ensuring long service life and reliable performance.

It meets all essential safety and health requirements as per CE regulations.

TECHNICAL DATA

Pressing force T 400

Motor power kW 22

Variable working speed mm/s 4-12

Approach speed mm/s 106

Return speed mm/s 125

Maximum pressure Bar 255

Stroke mm 750

Lower table mm 2,000 x 1,000

Ram plate mm 2,000 x 1,000

Maximum vertical clearance mm 1,000

Working height mm 960

Total height mm 3,560 + 600

Weight kg 39,500

STRUCTURE AND TABLE:

• The C-frame is fully welded and made exclusively from S355JR steel.

• Stabilized and machined after welding to ensure perfect parallelism and precision.

Bcsdpjwkv A Nsfx Ahwow

• Calculated and designed using finite element analysis software.

• The upper table ensures perfect alignment thanks to four lateral cylindrical guides (80 mm diameter) fitted with maintenance-free bimetallic bushings.

CYLINDER AND HYDRAULIC UNIT

• Main cylinder is single-acting, jacketed, with a chrome-plated piston and maintenance-free, wear-resistant guides.

• Two side-mounted double-acting cylinders with chrome-plated pistons and wear-resistant guides allow rapid advance and return speeds.

• Equipped with two independent hydraulic safety blocks.

• Motorized hydraulic unit with pre-fill valve for advance and return. Constant power pump with variable flow rate.

• Fitted with a directional valve, pressure relief valve, decompression valve, and an air-oil cooling system.

• Glycerin manometer with tonnage indicator.

ELECTRICAL INSTALLATION AND SAFETY

• Includes a SIEMENS safety PLC, model SIMATIC S7 1200, and a 7” touchscreen, model KTP-700 COMFORT, installed in the control cabinet. Allows programming of semi-automatic and automatic operating modes, output, stroke, and dwell time. Offers a storage capacity of 300 recipes, with each recipe allowing pre-programming of all parameters.

• All electrical and hydraulic controls are redundant and self-monitored. Includes an additional safety block and built-in self-monitoring devices for controls and safety circuits. Includes verification and certification of correct functionality and safety distances for light curtains.

• Operation via a low-voltage electric foot pedal.

• For safety, the system is equipped with Category IV safety laser and workspace protection with light curtains.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

We are offering a new or rebuilt version of this press.

The press will be available for sale by the customer in Q2-Q3 2026, as the project timeline has been extended.

The hydraulic press CF-400E/NC is part of the CF/NC series and has been specifically developed for the straightening of railway rails.

It is equipped with an upper and lower table made from machined C45E steel with DIN 650 T-slots.

The press uses an optimized hydraulic system with a pressure of less than 255 bar, ensuring long service life and reliable performance.

It meets all essential safety and health requirements as per CE regulations.

TECHNICAL DATA

Pressing force T 400

Motor power kW 22

Variable working speed mm/s 4-12

Approach speed mm/s 106

Return speed mm/s 125

Maximum pressure Bar 255

Stroke mm 750

Lower table mm 2,000 x 1,000

Ram plate mm 2,000 x 1,000

Maximum vertical clearance mm 1,000

Working height mm 960

Total height mm 3,560 + 600

Weight kg 39,500

STRUCTURE AND TABLE:

• The C-frame is fully welded and made exclusively from S355JR steel.

• Stabilized and machined after welding to ensure perfect parallelism and precision.

Bcsdpjwkv A Nsfx Ahwow

• Calculated and designed using finite element analysis software.

• The upper table ensures perfect alignment thanks to four lateral cylindrical guides (80 mm diameter) fitted with maintenance-free bimetallic bushings.

CYLINDER AND HYDRAULIC UNIT

• Main cylinder is single-acting, jacketed, with a chrome-plated piston and maintenance-free, wear-resistant guides.

• Two side-mounted double-acting cylinders with chrome-plated pistons and wear-resistant guides allow rapid advance and return speeds.

• Equipped with two independent hydraulic safety blocks.

• Motorized hydraulic unit with pre-fill valve for advance and return. Constant power pump with variable flow rate.

• Fitted with a directional valve, pressure relief valve, decompression valve, and an air-oil cooling system.

• Glycerin manometer with tonnage indicator.

ELECTRICAL INSTALLATION AND SAFETY

• Includes a SIEMENS safety PLC, model SIMATIC S7 1200, and a 7” touchscreen, model KTP-700 COMFORT, installed in the control cabinet. Allows programming of semi-automatic and automatic operating modes, output, stroke, and dwell time. Offers a storage capacity of 300 recipes, with each recipe allowing pre-programming of all parameters.

• All electrical and hydraulic controls are redundant and self-monitored. Includes an additional safety block and built-in self-monitoring devices for controls and safety circuits. Includes verification and certification of correct functionality and safety distances for light curtains.

• Operation via a low-voltage electric foot pedal.

• For safety, the system is equipped with Category IV safety laser and workspace protection with light curtains.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2025

Kirim permintaan

Telepon & Faks

+34 973 3... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Mudersbach

Mudersbach

11.201 km

Mesin bending bulat

Isitan4R HMS 1270 x 130

Isitan4R HMS 1270 x 130

Iklan kecil

Gelsenkirchen

Gelsenkirchen

11.241 km

Tekan hidrolik

HidrobrasilDoppelständerpresse 400 Tonnen

HidrobrasilDoppelständerpresse 400 Tonnen

Iklan kecil

Ciriè

Ciriè

11.352 km

Pers hidrolik

MOSSINIPO/2M/P2000

MOSSINIPO/2M/P2000

Iklan kecil

Babberich

Babberich

11.297 km

Mesin Cetak Halaman Pembentuk Hidraulik 1000 T

URSVIKENVPF 1000

URSVIKENVPF 1000

Iklan kecil

Cesena

Cesena

11.007 km

Mesin pembengkok bulat

MG3ROLL3000X50MM

MG3ROLL3000X50MM

Iklan kecil

Bellpuig

Bellpuig

11.963 km

Alat press pelurus

HidrogarneSH-250

HidrogarneSH-250

Iklan kecil

Root

Root

11.253 km

Mesin EDM CNC

AGIE CHARMILLESAC CLASSIC V2

AGIE CHARMILLESAC CLASSIC V2

Iklan kecil

Bellpuig

Bellpuig

11.963 km

Tekan hidrolik

Hidrogarne/GarnetMV-800/NC SINCRO

Hidrogarne/GarnetMV-800/NC SINCRO

Iklan kecil

Deinze

Deinze

11.500 km

Tekan horizontal

Van De GraafHHS 400 ton

Van De GraafHHS 400 ton

Iklan kecil

Austria

Austria

10.686 km

4 gulung hidrolik Tekuk

KK-IndustriesCY4R-HHS 510-30/45

KK-IndustriesCY4R-HHS 510-30/45

Iklan Anda telah berhasil dihapus

Terjadi kesalahan