SEBAGAI 100 (PERALATAN SEWA)Hosokawa Alpine

AS Aeroplex

SEBAGAI 100 (PERALATAN SEWA)

Hosokawa Alpine

AS Aeroplex

tahun pembuatan

2023

Kondisi

Baru

Lokasi

Augsburg

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- SEBAGAI 100 (PERALATAN SEWA)

- pabrikan:

- Hosokawa Alpine

- Model:

- AS Aeroplex

- tahun pembuatan:

- 2023

- Kondisi:

- baru

- fungsi:

- berfungsi sepenuhnya

Harga & Lokasi

- Lokasi:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

- penyewaan:

- dimungkinkan

Hubungi

Rincian penawaran

- ID iklan:

- A14383945

- pembaruan:

- terakhir pada 10.02.2025

Deskripsi

Hosokawa Alpine AS 100 Aeroplex Rental System

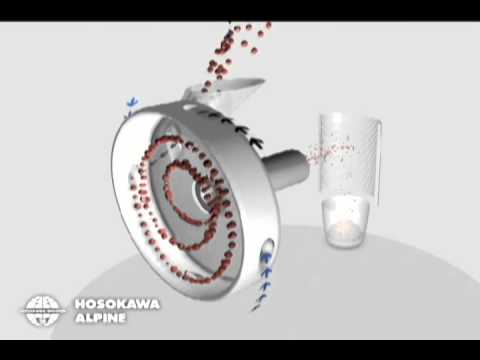

The Hosokawa Alpine Aeroplex AS spiral jet mill is a simple jet micronizer without a dynamic classifier (unlike the Hosokawa Alpine AFG), allowing for ultra-fine micronization, achieving particle sizes between 10 and 150µm for various products. It is primarily used for processing dry, non-abrasive materials with hardness up to 3 Mohs, although certain models can be equipped with abrasion-resistant liners. The design of this mill—without moving parts (therefore no bearings or lubrication)—makes it ideal for applications in the pharmaceutical and food industries, but it is also suitable for chemical processing, for instance.

The grinding occurs inside the milling chamber, where product is accelerated by compressed gas injected through the grinding nozzles, causing the particles to collide with each other, thereby fracturing and reducing their size. Once sufficiently fine, the particles are drawn to the central outlet of the mill, which functions as a static classifier. The particle size cut-off is not as precise as with the AFG (which is equipped with a classifier wheel). The next step is typically discharge from the system via a cyclone or air filter. Due to the quantity of air required, the temperature increase is significantly lower compared to other granulation and grinding technologies. The final particle size distribution can be easily adjusted by changing various parameters, such as gas pressure in the grinding nozzles or product injector, air volume, feed rate, and so on.

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Exclusively original components used

Cedjq A T Iljpfx Adpehc

Original manufacturer's warranty included

Guaranteed supply of spare parts by the manufacturer

Short delivery times

Prior to delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine is customized to your specific requirements

Can be supplied with all required peripherals or adapted to fit your existing production plant

We are also interested in buying back used HOSOKAWA ALPINE equipment

Technical details

Stainless steel construction, pharmaceutical-grade design

No explosion protection (NPSR); inert atmosphere operation (N2) possible

Batch operation, typically for a few grams (depending on material)

Scope of supply

Complete compact system, including dosing channel, Aeroplex AS spiral jet mill, manual controls, and filter

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

The Hosokawa Alpine Aeroplex AS spiral jet mill is a simple jet micronizer without a dynamic classifier (unlike the Hosokawa Alpine AFG), allowing for ultra-fine micronization, achieving particle sizes between 10 and 150µm for various products. It is primarily used for processing dry, non-abrasive materials with hardness up to 3 Mohs, although certain models can be equipped with abrasion-resistant liners. The design of this mill—without moving parts (therefore no bearings or lubrication)—makes it ideal for applications in the pharmaceutical and food industries, but it is also suitable for chemical processing, for instance.

The grinding occurs inside the milling chamber, where product is accelerated by compressed gas injected through the grinding nozzles, causing the particles to collide with each other, thereby fracturing and reducing their size. Once sufficiently fine, the particles are drawn to the central outlet of the mill, which functions as a static classifier. The particle size cut-off is not as precise as with the AFG (which is equipped with a classifier wheel). The next step is typically discharge from the system via a cyclone or air filter. Due to the quantity of air required, the temperature increase is significantly lower compared to other granulation and grinding technologies. The final particle size distribution can be easily adjusted by changing various parameters, such as gas pressure in the grinding nozzles or product injector, air volume, feed rate, and so on.

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Exclusively original components used

Cedjq A T Iljpfx Adpehc

Original manufacturer's warranty included

Guaranteed supply of spare parts by the manufacturer

Short delivery times

Prior to delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine is customized to your specific requirements

Can be supplied with all required peripherals or adapted to fit your existing production plant

We are also interested in buying back used HOSOKAWA ALPINE equipment

Technical details

Stainless steel construction, pharmaceutical-grade design

No explosion protection (NPSR); inert atmosphere operation (N2) possible

Batch operation, typically for a few grams (depending on material)

Scope of supply

Complete compact system, including dosing channel, Aeroplex AS spiral jet mill, manual controls, and filter

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2019

Kirim permintaan

Telepon & Faks

+49 821 2... iklan

Iklan Anda telah berhasil dihapus

Terjadi kesalahan