Mengklasifikasikan pabrikHosokawa Alpine

ZPS 315

Mengklasifikasikan pabrik

Hosokawa Alpine

ZPS 315

tahun pembuatan

1996

Kondisi

Bekas

Lokasi

Augsburg

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Mengklasifikasikan pabrik

- pabrikan:

- Hosokawa Alpine

- Model:

- ZPS 315

- tahun pembuatan:

- 1996

- Kondisi:

- diremajakan ulang (bekas)

Harga & Lokasi

- Lokasi:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

Hubungi

Penjualan mesin

Apakah Anda sudah mengiklankan mesin bekas Anda?

Jual melalui Machineseeker tanpa komisi.

Lebih lanjut tentang penjualan mesin

Lebih lanjut tentang penjualan mesin

Rincian penawaran

- ID iklan:

- A8823965

- pembaruan:

- terakhir pada 10.02.2025

Deskripsi

Molino clasificador usado Hosokawa Alpine Zirkoplex ZPS 315 classifier mill

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Use of original components exclusively

Original manufacturer's warranty

Guaranteed spare parts supply by the manufacturer

Reduced delivery times

Prior to delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine is customized to your specific requirements

Option to supply any required peripherals or retrofit to your existing production plant

Codpfokqlf Ssx Ag Usrh

We are also interested in repurchasing unused HOSOKAWA ALPINE equipment

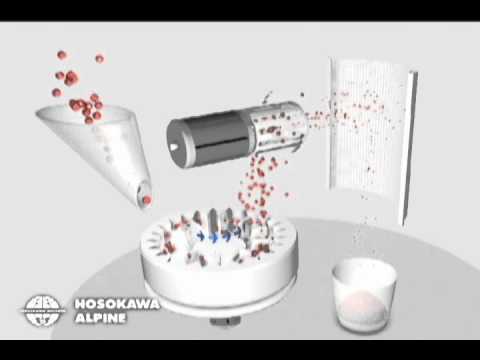

The Hosokawa Alpine Zirkoplex ZPS classifier mill is ideal for fine grinding of various dry materials with precise control of the cut point or maximum particle size, thanks to the integrated classifier wheel design. It can be used to pulverize a variety of products across different industries where micronization is required, such as minerals, chemicals, food, pharmaceuticals, and more. Grinding occurs at the bottom of the mill where a rotating plate equipped with grinding tools (hammers or pins) impacts and accelerates the particles against the internal grinding track (liner) to break them down. In the same chamber, airflow carries the fine product to the classifier wheel, where oversized particles are rejected and sent back for further grinding, while fine particles pass through to the next step, typically filtration. The necessary process air means only minimal temperature increase is expected during grinding, compared to other size reduction technologies. The final particle size distribution can be easily adjusted by changing various parameters, such as the rotor speed, classifier wheel speed, air volume, feed rate, etc.

Material of construction: stainless steel for product-contact parts

No wear protection

Equipment without explosion protection (NPSR), not ATEX-compliant

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, one set of internal grinding tools, and installation base/table.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Use of original components exclusively

Original manufacturer's warranty

Guaranteed spare parts supply by the manufacturer

Reduced delivery times

Prior to delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine is customized to your specific requirements

Option to supply any required peripherals or retrofit to your existing production plant

Codpfokqlf Ssx Ag Usrh

We are also interested in repurchasing unused HOSOKAWA ALPINE equipment

The Hosokawa Alpine Zirkoplex ZPS classifier mill is ideal for fine grinding of various dry materials with precise control of the cut point or maximum particle size, thanks to the integrated classifier wheel design. It can be used to pulverize a variety of products across different industries where micronization is required, such as minerals, chemicals, food, pharmaceuticals, and more. Grinding occurs at the bottom of the mill where a rotating plate equipped with grinding tools (hammers or pins) impacts and accelerates the particles against the internal grinding track (liner) to break them down. In the same chamber, airflow carries the fine product to the classifier wheel, where oversized particles are rejected and sent back for further grinding, while fine particles pass through to the next step, typically filtration. The necessary process air means only minimal temperature increase is expected during grinding, compared to other size reduction technologies. The final particle size distribution can be easily adjusted by changing various parameters, such as the rotor speed, classifier wheel speed, air volume, feed rate, etc.

Material of construction: stainless steel for product-contact parts

No wear protection

Equipment without explosion protection (NPSR), not ATEX-compliant

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, one set of internal grinding tools, and installation base/table.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2019

Kirim permintaan

Telepon & Faks

+49 821 2... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

iklan kecil

Augsburg

Augsburg

11.045 km

Mengklasifikasikan pabrik

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

iklan kecil

Arnsberg

Arnsberg

11.187 km

Pabrik pengklasifikasi

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

Iklan Anda telah berhasil dihapus

Terjadi kesalahan