Beli Mesin penggiling plastik bekas (117)

Białogard

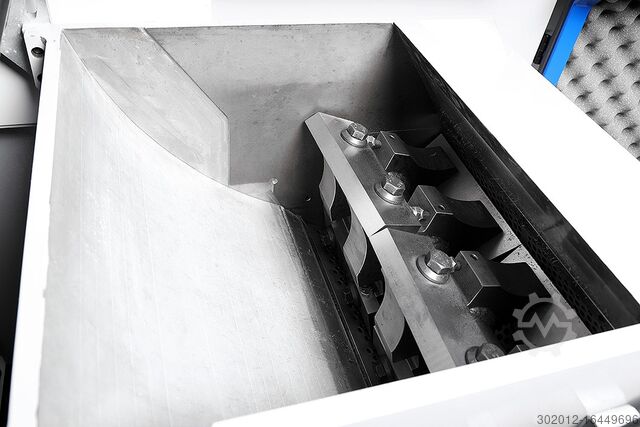

Białogard Mesin pemotong 3 kW

TRIA22-20/BL-T

Białogard

Białogard Mesin pemotong 3 kW

TRIA22-20/BL-T

Białogard

Białogard Granulator

PRMMGK2121R-1

Białogard

Białogard Pabrik

Motan40-20/BL-T MT

Białogard

Białogard Mesin pemotong 3 kW

TRIA22-20 BL-T

Temukan lebih banyak mesin bekas

Białogard

Białogard Mesin pemotong 3 kW

TRIA22-20 BL-T

Białogard

Białogard Mesin pemotong 3 kW

TRIA22-18 BL-T

Białogard

Białogard Mesin pemotong 3 kW

TRIA22-20 BL-T

Raitenbuch

Raitenbuch Lini lengkap pabrik pemotong Alpine

Alpine60/100 CL

Sinsheim

Sinsheim Pabrik Halus

NEUE HERBOLDZM 800

Berlin

Berlin Granulator

Tria80-40 TE-SL

Berlin

Berlin Granulator

Herbold

Brahlstorf

Brahlstorf Pabrik pengurangan ukuran

ZERMAGSL 180/180

Brahlstorf

Brahlstorf Pabrik pemotongan yang berjalan lambat

ZERMAGSL 300/400

Brahlstorf

Brahlstorf Penggiling samping

ZERMAGSL 180/430

Brahlstorf

Brahlstorf Granulator kecepatan tinggi

ZERMAGST 250/450

Brahlstorf

Brahlstorf Penggiling samping

ZERMAGSL 180/180

Buchholz in der Nordheide

Buchholz in der Nordheide Mesin pencacah

ZermaGST 250/450

Buchholz in der Nordheide

Buchholz in der Nordheide Pabrik Pemotongan CM H 100

CrushmasterH 100

Buchholz in der Nordheide

Buchholz in der Nordheide Pabrik Pemotongan CM S 60

CrushmasterS 60

Buchholz in der Nordheide

Buchholz in der Nordheide Mesin pencacah

ZERMAGSL 180/300

Buchholz in der Nordheide

Buchholz in der Nordheide Pabrik Pemotongan CM S 70

CrushmasterS 70

Buchholz in der Nordheide

Buchholz in der Nordheide Granulator

ZERMAGSL 300/600

Buchholz in der Nordheide

Buchholz in der Nordheide Pabrik Pemotongan CM G 30

CrushmasterG 30

Buchholz in der Nordheide

Buchholz in der Nordheide