Gergaji pitaCORMAK

HBS320

Gergaji pita

CORMAK

HBS320

harga tetap ditambah PPN

€1.670

Tahun pembuatan

2025

Kondisi

Baru

Lokasi

Siedlce

Gambar menunjukkan

Tampilkan peta

Data mesin

Harga & Lokasi

harga tetap ditambah PPN

€1.670

- Lokasi:

- Brzeska 120, 08-110 Siedlce, Polska

Hubungi

Rincian penawaran

- ID iklan:

- A8117426

- Pembaruan:

- terakhir pada 16.12.2025

Deskripsi

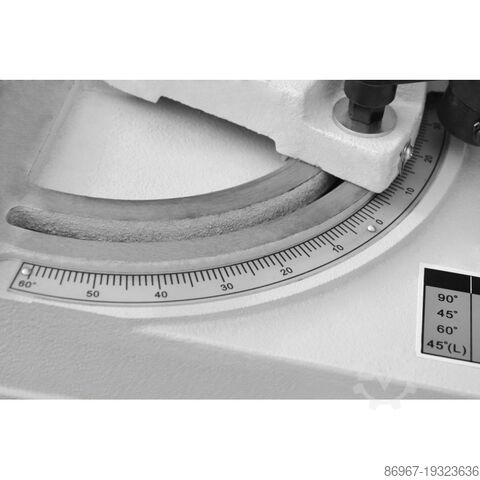

The CORMAK HBS320 is designed for double-sided miter cutting within a range from -45° to +60°. The machine’s construction is based on solutions and designs developed by Polish engineers. Precision and accuracy place it at the forefront among band saws capable of cutting up to 320 mm in width. A key advantage of the machine is its latest-generation hydraulic cylinder. The unit features a reinforced vise base and a quick-release vise mechanism.

Machine features

The CORMAK HBS320 metal band saw enables material cutting at any angle from -45° to +60°. The workpiece can be fed manually or by any feeding device. The feed during cutting is gravity-operated, utilizing oil flow in the hydraulic cylinder. The operator starts the machine by pressing the start button and sets the cutting speed. After completing the cycle, the machine stops automatically, and the operator raises the arm to the start position.

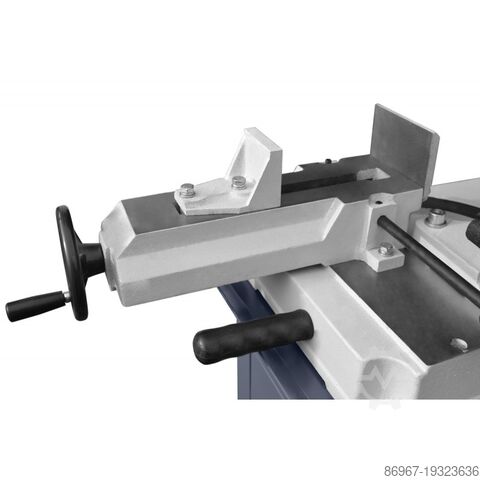

The saw arm is made from a very robust, single-piece gray cast-iron casting. Together with the 27 mm-wide saw blade, it ensures consistent multi-series cutting of structural, stainless, and tool steels. The vise is set in an adjustable bed and equipped with a quick-clamp function. The blade guides use ball bearings and carbide inserts, ensuring exceptional accuracy and straightness of cut. This greatly influences blade tracking, longevity, and overall cutting quality. Carbide guidance significantly reduces both machine and blade wear.

The base is a rigid welded body made from steel plates. Inside, there is a separate coolant tank with an electric pump. The upper part of the base is shaped as a tray for coolant drainage and chip collection during material cutting. The base is fitted with a cast-iron worktable with a double-sided pivoting arm and control panel.

Feed speed is controlled from the machine’s panel. Two cutting blade speeds are available: 44 and 88 m/min. In the lower arm position–after the material is cut–the blade drive stops automatically. Safety is ensured by blade guards and micro-switches that stop the motor after a cutting cycle or when any safety guard is opened. Additional protection includes automatic shutdown if the blade breaks.

Technical data

Ø MAX – 260 mm (straight cut)

H x W MAX – 320 x 160 mm (straight cut)

POWER SUPPLY – 3-phase 400V

TOTAL POWER – 1.5 kW

ARM DESCENT CONTROL – Hydraulic cylinder

BLADE DIMENSIONS – 2740 x 27 x 0.9 mm

BLADE SPEED – 44 / 88 m/min

Nkjdoi D Dgwopfx Aglst

VISE BASE HEIGHT – 920 mm

DIMENSIONS – 1400 x 880 x 1550 mm

WEIGHT – 280 kg

Cutting parameters

Angle

0º ----- ø260 320 x 160 255 x 255

45º R ø210 210 x 200 210 x 210

60º R ø135 135 x 130 130 x 130

45º L ø160 220 x 130 160 x 160

The listed price is NET. Price does not include shipping.

For further information, please contact us by phone or email. Visit our website to browse our full offer.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Machine features

The CORMAK HBS320 metal band saw enables material cutting at any angle from -45° to +60°. The workpiece can be fed manually or by any feeding device. The feed during cutting is gravity-operated, utilizing oil flow in the hydraulic cylinder. The operator starts the machine by pressing the start button and sets the cutting speed. After completing the cycle, the machine stops automatically, and the operator raises the arm to the start position.

The saw arm is made from a very robust, single-piece gray cast-iron casting. Together with the 27 mm-wide saw blade, it ensures consistent multi-series cutting of structural, stainless, and tool steels. The vise is set in an adjustable bed and equipped with a quick-clamp function. The blade guides use ball bearings and carbide inserts, ensuring exceptional accuracy and straightness of cut. This greatly influences blade tracking, longevity, and overall cutting quality. Carbide guidance significantly reduces both machine and blade wear.

The base is a rigid welded body made from steel plates. Inside, there is a separate coolant tank with an electric pump. The upper part of the base is shaped as a tray for coolant drainage and chip collection during material cutting. The base is fitted with a cast-iron worktable with a double-sided pivoting arm and control panel.

Feed speed is controlled from the machine’s panel. Two cutting blade speeds are available: 44 and 88 m/min. In the lower arm position–after the material is cut–the blade drive stops automatically. Safety is ensured by blade guards and micro-switches that stop the motor after a cutting cycle or when any safety guard is opened. Additional protection includes automatic shutdown if the blade breaks.

Technical data

Ø MAX – 260 mm (straight cut)

H x W MAX – 320 x 160 mm (straight cut)

POWER SUPPLY – 3-phase 400V

TOTAL POWER – 1.5 kW

ARM DESCENT CONTROL – Hydraulic cylinder

BLADE DIMENSIONS – 2740 x 27 x 0.9 mm

BLADE SPEED – 44 / 88 m/min

Nkjdoi D Dgwopfx Aglst

VISE BASE HEIGHT – 920 mm

DIMENSIONS – 1400 x 880 x 1550 mm

WEIGHT – 280 kg

Cutting parameters

Angle

0º ----- ø260 320 x 160 255 x 255

45º R ø210 210 x 200 210 x 210

60º R ø135 135 x 130 130 x 130

45º L ø160 220 x 130 160 x 160

The listed price is NET. Price does not include shipping.

For further information, please contact us by phone or email. Visit our website to browse our full offer.

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Kirim permintaan

Telepon & Faks

+48 25 63... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Iszkaszentgyörgy

Iszkaszentgyörgy

10.508 km

Mesin bubut tengah

TNMC6246 x 1500

TNMC6246 x 1500

Iklan kecil

Lemmer

Lemmer

11.303 km

Gergaji pita

MepShark 330HH

MepShark 330HH

Iklan kecil

Wasbek

Wasbek

10.999 km

Mesin bubut konvensional - Sinus 400/1500 D

KnuthSinus 400/1500 D

KnuthSinus 400/1500 D

Iklan kecil

Hessisch Lichtenau

Hessisch Lichtenau

11.072 km

Mesin finishing melalui getaran melingkar

WALTHER TROWALCLS-230

WALTHER TROWALCLS-230

Iklan kecil

Siedlce

Siedlce

10.199 km

Gergaji pita

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Iklan kecil

Hessisch Lichtenau

Hessisch Lichtenau

11.072 km

Mesin press bengkel hidrolik, mesin press broaching, mesin press broaching alur pasak, untuk broachi

Eigenbau MaVo5t-20

Eigenbau MaVo5t-20

Iklan kecil

Wesel

Wesel

11.275 km

Sistem penyelesaian getaran

ERBAEVP-RA 350 Rundvibrator mit Separierung

ERBAEVP-RA 350 Rundvibrator mit Separierung

Iklan kecil

Oftersheim

Oftersheim

11.190 km

Gergaji pita

KastoHBA 10x12

KastoHBA 10x12

Iklan kecil

Nauen

Nauen

10.842 km

Kontrol untuk lift penyimpanan

fse-Lifte Alle Typen

fse-Lifte Alle Typen

Iklan kecil

Mindelheim

Mindelheim

11.078 km

Gergaji pita ganda

MIOTALS 255 DG

MIOTALS 255 DG

Iklan Anda telah berhasil dihapus

Terjadi kesalahan