Mesin pembengkokJutec Biegesysteme GmbH & Co. KG

Biegesystem 6000 SB/D

Mesin pembengkok

Jutec Biegesysteme GmbH & Co. KG

Biegesystem 6000 SB/D

Tahun pembuatan

2025

Kondisi

Baru

Lokasi

Limburg an der Lahn

Gambar menunjukkan

Tampilkan peta

Data mesin

- Nama mesin:

- Mesin pembengkok

- Pabrikan:

- Jutec Biegesysteme GmbH & Co. KG

- Model:

- Biegesystem 6000 SB/D

- Nomor mesin:

- 1018

- Tahun pembuatan:

- 2025

- Kondisi:

- baru

Harga & Lokasi

- Lokasi:

- Robert-Bosch-Straße 8, 65549 Limburg an der Lahn, Deutschland

- penyewaan:

- dimungkinkan

Hubungi

Rincian penawaran

- ID iklan:

- A11721341

- Pembaruan:

- terakhir pada 24.04.2025

Deskripsi

THE POWERFUL BENDING MACHINE FOR WORKSHOP AND ON-SITE ASSEMBLY

Kwsdpfx Ageng Ax Sjlot

The compact and mobile bending machine enables precise and repeatable bending up to an outer diameter of 60 mm—either stationary or directly at the assembly site. A robust three-phase motor and precision gearbox ensure powerful drive performance.

Position detection directly on the bending axis provides optimal bending accuracy. Setting the bending angle is quick and easy via a user-friendly, menu-driven touchscreen interface, ensuring even more intuitive operation.

For more complex bending operations, up to 100 bending programs can be stored, each with a sequence of up to 8 bends per geometry. The multifunction controller allows variable adjustment of the bending speed for forward and return movement, and features a programmable overbend function to compensate for material springback.

Utilizing four material characteristic curves, the system automatically overbends the material to the required bending angle, delivering highly accurate bending results.

The “stationary tube, rotating tool” principle minimizes space requirements during bending. For thin-walled tubes, sliding shoes are used to achieve wrinkle-free bends and to produce bends with minimal deformation in materials such as stainless steel and copper.

With the PB20 profile bending attachment, flat, square, and round bars can be easily bent. The KBV small-radius bending device allows for extremely tight bend radii.

POSSIBLE APPLICATIONS:

• Plant engineering

• Hydraulic piping

• Meander bending

• Prototype construction

• Plumbing and heating installation

TECHNICAL DATA:

Bending capacity 6000SB: Ø 6 to 50 x 4 mm, single-phase 230 V

Bending capacity 6000D: Ø 6 to 60 x 4 mm

Bending capacity 6000DS: Ø 6 to 60 x 5 mm, three-phase 400 V

Bending capacity 6000D: Ø 6 to 60 x 4 mm, three-phase 400 V

• Min./max. bending radius: 36 mm/280 mm

• Optional large bending radii up to 500 mm

• Multifunctional machine control with 0.1° angle adjustment

• Maximum bending angle 240°

• 40 mm hexagonal shaft for quick tool change

• Safety foot switch with emergency stop

• Weight 110 kg

OPTIONAL ACCESSORIES:

• Profile bender PB20 – for bending flat and square bars up to max. 100 x 10 mm, round bars up to max. 20 mm

• Roller bender RB43 – mounts on the hex shaft of the bending axis. By switching to continuous bending mode, the bending system acts as a drive unit.

• Small-radius bending device KBV

• Special tools available on request

OUR ON-SITE SERVICE FOR YOU:

• Welcome to test production in our in-house demo room

• Consultation and information session at your premises

• Advice and processing of leasing/financed purchases

• Trade-in of your current machine

• Service contracts and on-site maintenance

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Kwsdpfx Ageng Ax Sjlot

The compact and mobile bending machine enables precise and repeatable bending up to an outer diameter of 60 mm—either stationary or directly at the assembly site. A robust three-phase motor and precision gearbox ensure powerful drive performance.

Position detection directly on the bending axis provides optimal bending accuracy. Setting the bending angle is quick and easy via a user-friendly, menu-driven touchscreen interface, ensuring even more intuitive operation.

For more complex bending operations, up to 100 bending programs can be stored, each with a sequence of up to 8 bends per geometry. The multifunction controller allows variable adjustment of the bending speed for forward and return movement, and features a programmable overbend function to compensate for material springback.

Utilizing four material characteristic curves, the system automatically overbends the material to the required bending angle, delivering highly accurate bending results.

The “stationary tube, rotating tool” principle minimizes space requirements during bending. For thin-walled tubes, sliding shoes are used to achieve wrinkle-free bends and to produce bends with minimal deformation in materials such as stainless steel and copper.

With the PB20 profile bending attachment, flat, square, and round bars can be easily bent. The KBV small-radius bending device allows for extremely tight bend radii.

POSSIBLE APPLICATIONS:

• Plant engineering

• Hydraulic piping

• Meander bending

• Prototype construction

• Plumbing and heating installation

TECHNICAL DATA:

Bending capacity 6000SB: Ø 6 to 50 x 4 mm, single-phase 230 V

Bending capacity 6000D: Ø 6 to 60 x 4 mm

Bending capacity 6000DS: Ø 6 to 60 x 5 mm, three-phase 400 V

Bending capacity 6000D: Ø 6 to 60 x 4 mm, three-phase 400 V

• Min./max. bending radius: 36 mm/280 mm

• Optional large bending radii up to 500 mm

• Multifunctional machine control with 0.1° angle adjustment

• Maximum bending angle 240°

• 40 mm hexagonal shaft for quick tool change

• Safety foot switch with emergency stop

• Weight 110 kg

OPTIONAL ACCESSORIES:

• Profile bender PB20 – for bending flat and square bars up to max. 100 x 10 mm, round bars up to max. 20 mm

• Roller bender RB43 – mounts on the hex shaft of the bending axis. By switching to continuous bending mode, the bending system acts as a drive unit.

• Small-radius bending device KBV

• Special tools available on request

OUR ON-SITE SERVICE FOR YOU:

• Welcome to test production in our in-house demo room

• Consultation and information session at your premises

• Advice and processing of leasing/financed purchases

• Trade-in of your current machine

• Service contracts and on-site maintenance

Iklan ini diterjemahkan secara otomatis. Kesalahan terjemahan mungkin terjadi.

Penyedia

Catatan: Daftar gratis atau masuk, untuk mengakses semua informasi.

Terdaftar sejak: 2023

Kirim permintaan

Telepon & Faks

+49 6431 ... iklan

Iklan-iklan ini juga mungkin menarik bagi Anda.

Iklan kecil

Böblingen

Böblingen

11.175 km

Mesin tekuk gulung

ERCOLINACE60H3

ERCOLINACE60H3

Iklan kecil

Hessisch Lichtenau

Hessisch Lichtenau

11.072 km

Mesin pembengkok pipa, mesin pembengkok dorn, mesin pembengkok untuk pipa dan profil; dengan servomo

SIEMENS1FK6061-7AF71-1EG0

SIEMENS1FK6061-7AF71-1EG0

Iklan kecil

Rödermark

Rödermark

11.160 km

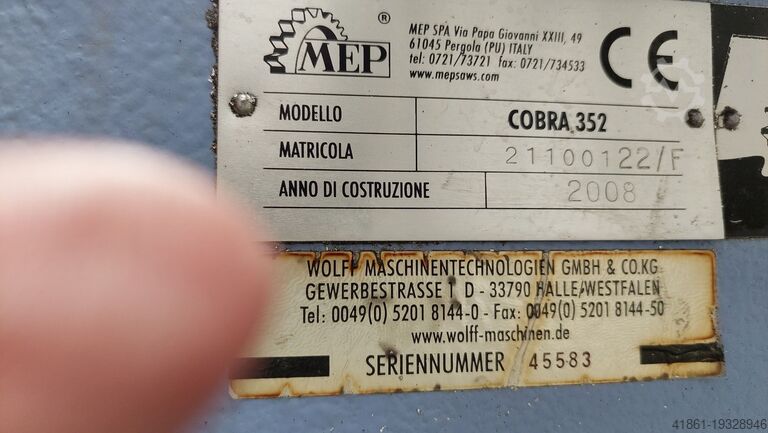

Gergaji mitra aluminium

MEPCobra 352

MEPCobra 352

Iklan kecil

Kępno

Kępno

10.501 km

Mesin pemotong horizontal

Zakład Ślurarski DZIERGWAPARK

Zakład Ślurarski DZIERGWAPARK

Iklan kecil

Kruševac

Kruševac

10.288 km

Gergaji Pengoptimal Sepenuhnya Otomatis 9m

ProfiFeed TechnologiesA550 Fully Automatic Mitre Aluminium Saw

ProfiFeed TechnologiesA550 Fully Automatic Mitre Aluminium Saw

Iklan kecil

Bergatreute

Bergatreute

11.137 km

Mesin penghancur kertas, chipper,

SIM2500 S

SIM2500 S

Iklan kecil

Ahaus

Ahaus

11.235 km

Mesin pembengkok tabung

ERCOLINAMB 42 M

ERCOLINAMB 42 M

Iklan kecil

Limburg an der Lahn

Limburg an der Lahn

11.204 km

Mesin tekuk tabung, mesin tekuk mandrel

Jutec Biegesysteme GmbH & Co. KGBiegesystem PB20

Jutec Biegesysteme GmbH & Co. KGBiegesystem PB20

Iklan kecil

Elz

Elz

11.207 km

Mesin pembengkok mandrel

Sommer Maschinenbau GmbHS45

Sommer Maschinenbau GmbHS45

Iklan kecil

Enschede

Enschede

11.244 km

Mesin bending cincin

AYEL-TECHPK 10-R

AYEL-TECHPK 10-R

Iklan Anda telah berhasil dihapus

Terjadi kesalahan