Beli File Paternoster bekas (708)

Urutkan hasil

- Harga terendah Harga tertinggi

- Iklan terbaru Iklan tertua

- Jarak terpendek Jarak maksimum

- Tahun pembuatan terbaru Tahun pembuatan tertua

- Pembaruan terbaru Pembaruan tertua

- Produsen dari A sampai Z Produsen dari Z ke A

- Relevansi

- Harga terendah

- harga

- Harga tertinggi

- harga

- Iklan terbaru

- Tanggal pengaturan

- Iklan tertua

- Tanggal pengaturan

- Jarak terpendek

- jarak

- Jarak maksimum

- jarak

- Tahun pembuatan terbaru

- tahun pembuatan

- Tahun pembuatan tertua

- tahun pembuatan

- Pembaruan terbaru

- pembaruan

- Pembaruan tertua

- pembaruan

- Produsen dari A sampai Z

- pabrikan

- Produsen dari Z ke A

- pabrikan

- Penamaan dari A ke Z

- Penunjukan

- Penamaan dari Z ke A

- Penunjukan

- Model dari A hingga Z

- Model

- Model dari Z ke A

- Model

- Referensi terendah

- referensi

- Referensi tertinggi

- referensi

- Waktu operasional terpendek

- Waktu operasional

- Waktu operasional terpanjang

- Waktu operasional

- relevansi

- relevansi

Iklan kecil

Vechta

Vechta

11.136 km

Mesin penghancur poros tunggal

NEUENHAUSERTARGO 3000

Hubungi

Kondisi: diremaj di bengkel (bekas), Tahun pembuatan: 2017, Fungsionalitas: berfungsi sepenuhnya, daya: 405,26 kW (551,00 hp), Mobile crushing plant on crawler tracks.

Diesel engine: 551 HP

Folding discharge conveyor

Overbelt magnet (neodymium)

Remote control

For detailed description, see PDF file.

Dusdpju R Uaxsfx Abhsn

Iklan kecil

Aflenz Land

Aflenz Land

10.729 km

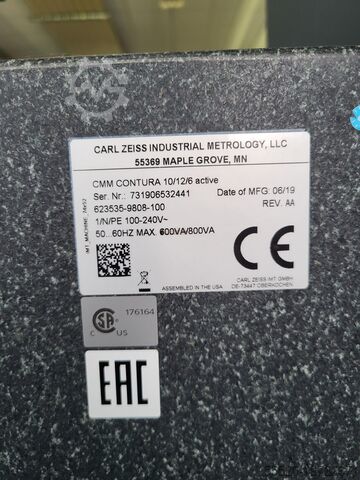

Mesin pengukur koordinat ZEISS

ZeissCMM CONTURA 10126 active

Hubungi

Kondisi: hampir baru (bekas), Tahun pembuatan: 2019, jam operasional: 50 h, Fungsionalitas: berfungsi sepenuhnya, rentang pengukuran sumbu X: 1.000 mm, rentang pengukuran sumbu Y: 1.200 mm, rentang pengukuran sumbu Z: 600 mm, Deskripsi mesin: Mesin pengukur koordinat CNC ZEISS (CMM) dengan desain portal - Volume pengukuran X = 1000 mm, Y = 1200 mm, Z = 600 mm - Tinggi meja TH = 850 mm (standar) - Disiapkan untuk sensor aktif taktil - Teknologi pengukuran VAST navigator (pemindaian aktif taktil) HANYA 50 JAM OPERASI – SEHINGGA SEPERTI BARU PERALATAN SESUAI KONFIRMASI PESANAN – LIHAT FILE PDF TERLAMPIR

Duodpfew H Rfdjx Abhen

Iklan kecil

Nattheim

Nattheim

11.085 km

Pusat permesinan CNC

MorbidelliUniversal 3615 TV

Hubungi

Kondisi: bekas, Tahun pembuatan: 2008, · Working area X-Y-Z: 3,660 x 1,550 x 130 mm · Travel length X-Y: 4,200 x 2,000 mm Aggregate and Accessories Description (Basic) The machine base structure is a monolithic design made from thick-walled steel. It is reinforced with welded triangular plates throughout the entire machine bed, providing extreme stability. The use of a triangle shape with a broad base for all load-bearing elements is the key to ensuring long-term precision and stability. The machine layout allows the operator to achieve an optimal workflow with minimal space requirements. This foundation provides a balanced, secure base for the processing unit with excellent load distribution. The mobile portal-type aggregate carrier is constructed as a solid monoblock. It is positioned in the X-axis along ground prismatic guides via recirculating ball carriages. The working aggregate is mounted to this portal carrier on ground prismatic guides and recirculating ball carriages. Axis Movement: Y and Z axes are driven by precision-ground recirculating ball screws of the highest accuracy class. The X-axis drive is a backlash-free, preloaded precision rack-and-pinion system. This ensures even load distribution during positioning, which is crucial for balanced movements even in complex operations. Axis movements are realized by brushless AC servo motors. These provide outstanding positioning speeds with very short ramp times. Additionally, all motors feature fully integrated measurement systems, making this drivetrain entirely maintenance-free. · Rapid traverse in X: 40 m/min · Rapid traverse in Y: 60 m/min · Rapid traverse in Z: 22.5 m/min Vacuum System (Basic) · Vacuum pump: 100 cbm/h · Power: 2.5 kW · Max. vacuum (connection): 0.9 bar Control / Electrical Cabinet · Office PC or industrial PC (see options) · Basic NC control: ESA-GV KVARA 6.0 · Cable remote control with main functions ELECTRICAL/ELECTRONIC CNC CONTROL Universal is equipped with a powerful NC control system. The integrated office PC provides an unmatched level of familiarity to the NC system: the software operates on Windows XP, allowing fast and simple programming—even for inexperienced users. The system is open and allows connections to a CD-ROM drive, audio card, barcode reader, modem, printer, scanner systems, etc. Installation of any network systems or commercially available CAD programs is also possible. To save space, the electrical cabinet is mounted beneath the machine table, while the operator uses a separately mobile, wheeled console that can be freely positioned. PROGRAMMING SYSTEM XILOG Software features: - Import of DXF files - Import of ASCII files - Operator interface available in native language (I - GB - F - D - E) - Linear and circular interpolation in three axes, linear in space, helical on selected plane - Assisted programming - Calculator for direct transfer of computed data - Graphical and syntax aids for drilling and milling operations - Parametric programming for repeating panel machining on different p

Djdpovvi Nzefx Abhoun

Iklan kecil

Nattheim

Nattheim

11.085 km

Pusat permesinan CNC

MorbidelliUniversal 3615 TV 4-Achs

Hubungi

Kondisi: bekas, Tahun pembuatan: 2008, · Working area X-Y-Z: 3,660 x 1,550 x 130 mm · Travel range X-Y: 4,200 x 2,000 mm Description of units and accessories (standard configuration) The base structure is a monolithic construction made of thick-walled steel. It is reinforced across the entire machine bed with welded triangular plates, providing exceptional stability. The triangular shape used for the load-bearing elements, with a wide base, is the secret to ensuring long-term precision and stability. The machine layout allows the operator an optimal workflow even with minimal space requirements. Thus, the base structure provides the machining unit with a balanced and secure foundation with particularly good load distribution. The moving portal-type aggregate carrier is constructed as a solid monoblock. It is positioned in the X direction on prismatically ground guides and recirculating ball bearing carriages. The working unit is also mounted on prismatic, ground guides and recirculating ball carriages on this mobile aggregate carrier. Axis movement: The drive system for the Y and Z axes uses ground recirculating ball screws of the highest precision class. The drive in the X-axis is via a backlash-free, preloaded precision rack-and-pinion drive. This ensures balanced load distribution during positioning. Such characteristics are essential for smooth movement even during more complex operations. The movement of the individual axes is performed by brushless AC servomotors. These motors offer excellent positioning speed due to very low ramp-up times. Furthermore, the measuring systems are fully integrated into these motors, making this drive type completely maintenance-free. · Rapid traverse speed in X: 40 m/min · Rapid traverse speed in Y: 60 m/min · Rapid traverse speed in Z: 22.5 m/min Vacuum system (standard) · Vacuum pump: 100 cbm/h · Power: 2.5 kW · Max. vacuum (connection): 0.9 bar Control / Control cabinet · Office PC or industrial PC (see options) · Standard NC control: ESA-GV KVARA 6.0 · Cable remote control with main functions ELECTRICAL/ELECTRONIC CNC CONTROL Universal is equipped with a powerful NC control. The integrated office PC gives the NC control an unmatched level of familiarity: the software operates on Windows XP, allowing fast and easy programming that is also user-friendly for inexperienced operators. The system is open, permitting the connection of a CD-ROM drive, sound card, barcode reader, modem, printer, scanning systems, etc. Additionally, all common network systems and commercially available CAD programs can be installed. To save space, the control cabinet is placed beneath the machine table, while the operator works at a separate, movable terminal on castors. PROGRAMMING SYSTEM XILOG Software features: - Import of DXF files - Import of ASCII files - User interface in the operator’s native language (available in languages: I - GB - F - D - E) - Straight line and circular interpolation in three axes, linear in space, spiral in the selected plane - supported programming - Calculator for direct data transfer - Graphic and syntax help for drilling and milling operations - Parametric programming, enabling identical panel machining on various

Dujdpfx Ajvvi Rfebhjn

Iklan kecil

Saerbeck

Saerbeck

11.190 km

Mesin pemotong laser

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

Hubungi

Kondisi: baru, Fungsionalitas: berfungsi sepenuhnya, Tahun pembuatan: 2025, jam operasional: 30 h, Perlengkapan: ekstraksi asap, ekstraksi debu, henti darurat, penghadang cahaya keselamatan, sistem pelumasan terpusat, Rohr laser cutting system, ideal entry-level solution.

Simplicity meets efficiency with the Durma HD-TC COMPACT 60250 entry-level tube laser. Perfect for workshops, metal fabricators, and similar businesses looking to take their first step into tube laser processing, this laser offers intuitive operation, reliable performance, and excellent value for money. Discover how the Durma HD-TC COMPACT 60250 can enhance your production with precise cuts and user-friendly technology, adding value to your operation.

Laser Power: 3 kW

Maximum Sheet Thickness:

- Mild steel: 12 mm

- Stainless steel: 6 mm

- Aluminium: 6 mm

- Copper: 3 mm

- Brass: 6 mm

Capacity:

- Maximum tube diameter: Ø250 mm

- Maximum square profile dimensions: 160x160 mm

- Maximum rectangular profile dimensions: 200x150 mm

- Minimum tube diameter: 16 mm

- Maximum material length: 6000 mm

- Minimum remnant length: 65 mm

- Unloading length: 3000 mm

- Semi-automatic unloading unit: Optional (6 m)

- Maximum material weight: 58 kg/m

- Maximum total workpiece weight: 350 kg

- Profile types that can be cut: round, square, rectangular, elliptical

- Open profile types that can be cut: I, C, L

- Maximum open profile dimensions: 240x240 mm

Dynamics:

- X-axis: 40 m/min

- Y-axis: 94 m/min

- Z-axis: 30 m/min

- A-axis (rotational): 510°/s

Precision:

Dujdpfsrkntcjx Abhen

- Positioning accuracy: ±0.2 mm

- Positioning deviation: ±0.015 mm

- Positioning repeatability: ±0.05 mm

- Tube center detection with capacitive sensor: Yes

Configurable options available.

LASER POWER UPGRADES:

- Upgrade to DURMA LASER SOURCE BRILASE 4 kW ADVANCED fiber laser source (incl. chiller) + Durma head

- Upgrade to DURMA LASER SOURCE BRILASE 6 kW ADVANCED fiber laser source (incl. chiller) + Durma head

OPTIONS:

- Air filtration system (40 bar N₂ + 16 bar O₂ + 16 bar air)

- Air filtration system (40 bar N₂ + 16 bar O₂ + 40 bar air)

- CNC bevel head (+/- 45°)

- Semi-automatic front loading system

- Unloading table (6 m) with conveyor belt

- Unloading table (3 m) with conveyor belt

- Additional dongle software

- Transformer 220, 440, 575V

SOFTWARE OPTIONS:

- Durma Cloud license + D-Mobile + Smart Watch

- STEP importer

Temukan lebih banyak mesin bekas

Iklan kecil

Hørning

Hørning

10.949 km

Planer empat sisi

KUPERTYP SWT 23 XL - 5

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2010, Fungsionalitas: berfungsi sepenuhnya, Panjang meja 2000 mm. Lebar kerja: maks. 230 mm / min. 18 mm. Tinggi kerja: maks. 150 mm / min. 8 mm. Tinggi dapat diatur secara elektrik. Kecepatan 7-36 m/menit. Motor 3,7 kW, kardang. 5 pcs spindel Ø 40 mm: bawah + kanan + kiri + atas + bawah (spesifikasi lihat file terlampir). Layar sentuh Siemens. Lihat semua fitur teknis pada file terlampir.

Dujdpfxsxr U Azs Abhjn

Iklan kecil

Hørning

Hørning

10.949 km

DEP

CMLMOD. STDA 336

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2010, Fungsionalitas: berfungsi sepenuhnya, CML - DEP LINI FLEKSIBEL UNTUK PRODUKSI ELEMEN JENDELA SESUAI DENGAN DENAH LY-09-087-05 TANGGAL 27/01/2010

01 KONVEYOR SABUK 1=4500 mm

02 TRANSFER "L" DENGAN ROLLER BERLAPIS PVC DAN PENAMPUNG

Dujdextaciopfx Abhen

03 TENONER DOUBLE END CML MOD. STDA 336

04 SISTEM KONTROL MESIN LENGKAP

LIHAT SPESIFIKASI TEKNIS PADA FILE PDF TERLAMPIR

Iklan kecil

Nördlingen

Nördlingen

11.062 km

Pusat pembubutan dan milling CNC

DMG MoriCLX 550

Hubungi

Kondisi: baik (bekas), Tahun pembuatan: 2019, jam operasional: 8.173 h, Fungsionalitas: berfungsi sepenuhnya, panjang pembubutan: 12.025 mm, diameter pembubutan: 480 mm, kecepatan spindel (min.): 3.250 rpm, jarak pergerakan sumbu X: 308 mm, jarak lintasan sumbu Y: 120 mm, jarak gerak sumbu Z: 1.240 mm, saluran batang: 102 mm, berat keseluruhan: 7.200 kg, model controller: DMG MORI SLIMline Multi-Touch Control, jenis kontrol: Kontrol CNC, en-GB: CLX 550 V6

2-axis universal lathe

with driven tools

incl. C-axis, Y-axis and counter spindle

Standard equipment:

1. Ergonomic DMG MORI SLIMline operator panel

2. Main spindle A2-8 with AC motor, drive power 22 / 33 kW (100/40% duty cycle), 3,250 rpm

3. Counter spindle A2-6 with ISM 52 synchro, drive power 13 / 14 kW, torque 171.5/192 Nm (100/40% duty cycle), 5,000 rpm

4. 12-position servo turret VDI 40 mount with Trifix® precision interface and 12 driven tool stations, drive shaft according to DIN 5480

5. Y-axis ±60 mm

6. Chip tray

Dusdpfxoyazdpo Abhjn

7. Hollow clamping device, max. bar capacity D 80 mm

8. Electronic handwheel

Drive power (100%/40% duty cycle) 22/33 kW and hydraulic clamping device with bar feed, diameter 102 mm (extra charge)

Differential pressure clamping for the main spindle

Bar package & interface

Option includes:

- Workpiece removal device for parts up to D 80 x 200 mm (D 100 x 200 mm with Option C-B7000G), max. workpiece weight 4 kg

- Interface for bar loader or bar loading device (DMG MORI standard interface)

- Hinged belt chip conveyor instead of chip tray

- 4-colour signal light

We additionally recommend the double cartridge filter option for coolant, especially for production environments with very high chip volume.

Automatic workpiece ejector

Counter spindle with internal coolant supply for chuck flushing.

Note: Option recommended for machines with workpiece removal device option.

External clamping flush for counter spindle.

Option recommended for machines with automation.

Differential pressure clamping for counter spindle.

Tailstock function for counter spindle, mechatronic control of tailstock force programmable (250-600 daN), incl. foot switch.

Only for CLX 550 V6.

Direct position measurement system X-, Y-axis.

Note: Option only for machines in version V4 and V6.

Manual tool measurement device in the working area, make: Marposs.

Documentation according to the "Technical Documentation Parts List"—included in the machine price.

Software option DXF import: conversion of DXF files to NC programs.

SIEMENS CNC

Tool monitoring system Easy Tool Monitor 1.0, monitoring per machining cut, with one monitoring limit. Simple learning function to determine the monitoring limit per tool per cut, manual adjustment/correction possible.

Technology cycle – alternating speed (turning)

Technology cycle: alternating speed for vibration-sensitive applications.

Note: We offer flexible financing solutions for all machines as well as a professional relocation service. Dismantling, transport, and expert installation—all from a single source. Billing according to individual terms and period. Contact us for your personal offer.

Iklan kecil

Lambsborn

Lambsborn

11.273 km

Pusat pemesinan

HOMAGBMG 311 Venture 316 M

Hubungi

Kondisi: sangat baik (bekas), Tahun pembuatan: 2013, Fungsionalitas: berfungsi sepenuhnya, nomor mesin/kendaraan: 0-201-08-2653, termasuk alat sesuai daftar (lihat dokumen PDF),

perlengkapan sesuai penawaran terlampir (lihat dokumen PDF),

No. Mesin: 0-201-08-2653,

Duedpfx Asybbhwsbhen

proses sekali jalan: 3300 x 1550 mm,

penukar piring otomatis 14 posisi,

dimensi sesuai brosur (lihat dokumen PDF),

akseoris sesuai foto

KONDISI SANGAT BAIK

Mesin dirawat setiap tahun dan dicek toleransinya

Perangkat lunak optimalisasi: PC85

WoodWop: HOMAG WoodWop 6.1

(dapat menggunakan file .mpr + .mprx)

Sistem operasi: Windows XP

Mesin siap untuk demo - silakan atur jadwal kunjungan bersama kami

Harga ex lokasi

Iklan kecil

Jerman

Jerman

11.248 km

WEMHÖNER Variopress Basic 1000S

WEMHÖNERVariopress Basic 1000S

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2018, produsen pengendali: SIEMENS, model controller: SIVATIC HMI, en

Djdpsx D Hy Ajfx Abhoun

Iklan kecil

Polandia

Polandia

11.248 km

MACRI Provar 6-45 U-D

MACRIProvar 6-45 U-D

Hubungi

Tahun pembuatan: 2018, Kondisi: siap digunakan (bekas), This 6-axis MACRI Provar 6-45 U-D was manufactured in 2018. It is a fully automatic CNC tube bending machine, distinguished by minimal use with only around 20 operating hours. The machine supports a maximum tube diameter of Ø45 × 4 mm and a usable tube length of 5,800 mm. Key performance features include a maximum bending speed of 150°/sec and a maximum feed rate of 1,000 mm/sec. Consider the opportunity to purchase this MACRI Provar 6-45 U-D profile bending machine. Contact us for further information.

Additional equipment

• Movable carriage support / support for wrinkle-free inserts / 2×1 m safety mat (aluminum) / Macri software installed on office PC (Windows 7) / rear unsupported bending system / hydraulic cylinder for square/rectangular tube opening / automatic material elasticity control system / tool sets

Dodpfoyap Upsx Abhsun

Machine benefits

Technical machine advantages

• Operating hours: approx. 20 hours, the machine was not used in production.

• Type: fully automatic CNC tube bending machine (6-axis)

• Max. tube diameter (round): Ø45 × 4 mm / min. tube diameter for variable radii: Ø35 × 2 mm (rm 10d) / usable tube length: 5800 mm / max. bending speed: 150°/sec (±0.1°) / max. feed speed: 1000 mm/sec (±0.1 mm) / max. clamp rotation speed: 450°/sec (±0.1°) / direction of rotation: right-hand / spindle movement (head movement): 6-axis (y, x, z, b1, b2, a)

• Installed power: 15 kW / voltage / frequency: 400 V / 50 Hz / machine dimensions (L×W×H): 6000 × 1200 × 1200 mm / weight (kg): 4500 kg / control cabinet dimensions: 900 × 600 × 1800 mm

• Control: industrial PC with Windows 7 / display: 19" LCD TFT SVGA touchscreen / control software: graphical Cartesian & CAD-based interface / functions: manual and semi-automatic operation, import of 3D files (e.g. SolidWorks)

Iklan kecil

Denmark

Denmark

11.248 km

DMG MORI CTX Beta 800 4a

DMG MORICTX Beta 800 4a

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2014, jam operasional: 48.973 h, produsen pengendali: SIEMENS, model controller: 840 D, jumlah sumbu: 3, Diese DMG MORI CTX Beta 800 4a was manufactured in 2014. It is equipped with a Siemens 840 D control unit, sub-spindle, and a bar feeder package for increased versatility. The machine features a 980-litre coolant system and a hinged belt conveyor for efficient operation. If you are looking for high-quality turning and milling machines, you should consider the DMG MORI CTX Beta 800 4a that we are offering for sale. Contact us for further information about this machine.

• 2 x 16-position Sauter Static Tool Turrets VID 30

• Siemens 840 D

• Eccentric turning and milling operations

• Tool change speed control

• Sub-spindle

• Glass scales for Y1, Z1, Z2, Z3, X1, X2, X3 axes

Additional Equipment

• 980-litre coolant system with 8 bar/20 L and 20 bar/40 L programmed via M-function

• Paternoster band filter

• Chuck flush device for main side

• Chuck flush device for sub-spindle side

• Coolant spray gun

• Hinged belt chip conveyor

• Bar feeder package

• Window cleaning with compressed air

Dujdpfx Ajx D Nd Djbhon

• SK package for aluminium machining

• Tool breakage detection Artis CTM

Iklan kecil

Velžys

Velžys

10.059 km

Qualitätsscanner für Glas, 2700 mm

VIPROTRONQuality Scanner 3D

Hubungi

Tahun pembuatan: 2022, Kondisi: hampir baru (bekas), Fungsionalitas: berfungsi sepenuhnya, de-hu-001

Duodpjx Eczfofx Abhsn

Iklan kecil

Jerman

Jerman

11.023 km

Gergaji pita - vertikal

MÖSSNER REKORDSSF 801

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 1972, Fungsionalitas: berfungsi sepenuhnya, en-GB

Dsdpfxovx Huge Abhoun

Iklan kecil

Hauzenberg

Hauzenberg

10.838 km

Mesin pemotong laser

LD-LaserLG-1313 3kW eco line

Hubungi

Kondisi: baru, Fungsionalitas: berfungsi sepenuhnya, Tahun pembuatan: 2025, jenis kontrol: Kontrol CNC, tingkat otomatisasi: otomatis, jenis aktuasi: listrik, jenis laser: laser serat, produsen sumber laser: MAX Photonics, daya laser: 1.500 W, ketebalan pelat baja (maks.): 15 mm, ketebalan maksimum lembaran baja tahan karat: 6 mm, tebal plat aluminium (maks.): 6 mm, ketebalan lembaran kuningan (maks.): 4 mm, frekuensi input: 50 Hz, jenis arus masuk: tiga fasa, jenis pendinginan: air, sambungan udara terkompresi: 8 batang, berat keseluruhan: 2.800 kg, Perlengkapan: Penandaan CE, ekstraksi asap, ekstraksi debu, henti darurat, penghadang cahaya keselamatan, sistem pelumasan terpusat, unit pendingin, Laser cutting machine with 3kW fiber laser

Our commitment is to offer highly precise, long-term stable, and yet affordable laser machines.

Our machines are ideal for workshops and repair operations.

A perfectly developed cutting parameter library is included, along with first-class service support.

Take advantage of our attractive leasing and hire purchase offers.

The cost-effective entry into laser cutting technology

Duodpfsyacw Rox Abhsn

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 metres installation space

- Top quality – schedule a viewing now!

Cutting capabilities:

- Steel sheet up to 22mm

- Stainless steel sheet up to 12mm

- Aluminium sheet up to 8mm

- Travel range approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

(i.e. a full medium-format sheet fits within the machine)

- Machine control in German

- Manual front door

- Comprehensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching

(compressed air/nitrogen, oxygen)

- Extensive cutting parameter file

- Incl. nesting module

- Very easy to operate

- High-performance laser chiller included

Sales are exclusively to business customers.

Delivery/advice/sales only in Germany/Austria/Switzerland.

Machine dimensions (approx.):

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 3000kg

Leasing or hire purchase is available through our financing partner.

Need a different laser power, table design, or table size?

No problem.

I’ll be happy to provide a tailored quotation.

Not sure which laser power suits your application?

Of course, I can carry out cutting trials according to your requirements. Almost anything is possible – from 0.5kW to 20kW laser power.

Iklan kecil

Hungaria

Hungaria

11.248 km

HAAS UMC-1000SS

HAASUMC-1000SS

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2020, kecepatan spindel (maks.): 15.000 rpm, jarak pergerakan sumbu X: 1.016 mm, jarak lintasan sumbu Y: 635 mm, jarak gerak sumbu Z: 635 mm, This 5-axis HAAS UMC-1000SS was manufactured in 2020. It offers a large working area with X, Y, and Z travels of 1016 mm, 635 mm, and 635 mm respectively. Ideal for complex geometries and multi-sided machining. Take advantage of the opportunity to purchase this HAAS UMC-1000SS universal machining center. Contact us for further information.

Additional equipment

Dodpjyalh Ssfx Abhjun

• Belt-driven chip conveyor

• Export packaging

• 8-station pallet pool for UMC

• UMC spare tool storage (1 unit)

• Through-Tool Air Blast (TAB)

• Additional coolant filtration

• Chip pan filter set

Machine advantages

Technical machine advantages

• Standard program memory: 1 GB / coolant tank capacity: 55 gallons / CNC control cabinet cooling / dynamic work offsets and tool center point control (DWO/TCPC) / fast power failure detection module / Ethernet interface / HaasConnect: remote monitoring / HaasDrop: wireless file transfer

• Second home position / high-speed machining (HSM) / media display via M-code (M130) / remote jog handle with touchscreen / encoder / synchronized tapping / Safe Run (safety restart function) / 1-year standard warranty

• Enclosure with mist extraction / variable coolant pressure / Wi-Fi connectivity for Haas control / Wireless Intuitive Probing System (WIPS) / side-mounted high-speed tool changer – 50+1 tools / CT (SK) 40 spindle taper

• Through-spindle coolant (TSC): 69 bar (1000 psi)

Additional information

Machine still under power

Iklan kecil

Jerman

Jerman

11.248 km

SPINNER TTS 42

SPINNERTTS 42

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2020, jam operasional: 25.585 h, kecepatan spindel (maks.): 7.000 rpm, produsen pengendali: FANUC, model controller: Series 31i-MODEL B, This SPINNER TTS 42 lathe was manufactured in Germany in 2020 and has 25,585 operating hours. It is equipped with a Fanuc Series 31i-MODEL B control unit. The machine has a spindle speed of 7,000 rpm. Further details can be found in the attached PDF file with the technical specifications.

Machine Benefits

Qualitative Machine Advantages

• Unimag interface for bar feeders

• Parts conveyor belt

• Spinner bar feeder, servo type. Manufacturer Spinner, for spindles up to 42 mm bore, for material diameters of 4–42 mm, length up to 3,200 mm

• 10x external turning tool holders

• 12x boring bar holders, d=32

• 3x recessed boring bar holders

• 6x straight driven tool holders (AGW)

• 3x axial driven tool holders (AGW)

• Materials processed so far: aluminium, brass

Technical Machine Advantages

Dujdpfx Asyail Uobhjn

• Spindle 2 (counter spindle) version up to 7,000 rpm – 42 mm

• Turret 1: 12-position with CNC servo drive, Turret 2: 12-position with CNC servo drive, Turret 3: 12-position with CNC servo drive (DMJGMX)

• Integrated ejector unit in the counter spindle for ejecting parts into the part catcher

• Signal lamp on top of the machine in three colors red/yellow/green as a status indicator

• Chip conveyor as a hinged belt conveyor discharging to the right, incl. integrated coolant tank and return pump

• Coolant system as an additional tank incl. submersible pump 80l/4bar, high-pressure pump up to 80bar / 19.5l/min

• Rinsing gun in the working area

• Holder for probe on the machine bed as preparation for use

• Probe for switching between tool measurement in 3 axes

• Extraction d=200 in the working area for connection to the extraction system

Iklan kecil

Dunaharaszti

Dunaharaszti

10.447 km

Printer 3D Replicator Z18

Markerbot ReplicatorZ18

Hubungi

Kondisi: sangat baik (bekas), Fungsionalitas: berfungsi sepenuhnya, nomor mesin/kendaraan: Z50009537, Tahun pembuatan: 2018, jam operasional: 167 h, panjang total: 50 mm, tinggi total: 81 mm, lebar total: 57 mm, jenis arus masuk: Arus searah (DC), berat keseluruhan: 41 kg, tegangan masuk: 220 V, lebar meja: 305 mm, panjang meja: 305 mm, For sale: a professional-grade Replicator Z18 3D printer, barely used (only 166 operating hours), offered well below market price.

Key Features:

- Extra-large build volume: 30.5 x 30.5 x 45.7 cm

- Supported by the new, user-friendly MakerBot Replicator 3D Printing Platform

- Cloud-based system and app support

- MakerBot Replicator Smart Extruder, advanced motion control, and axis design

- Onboard camera and diagnostics, guided calibration

- High build volume enables rapid prototyping and model production

- 11% larger build volume compared to the MakerBot Replicator 2

- Build volume: 25.2 L x 19.9 W x 15.0 H cm (7,522 cm³)

- Easily and quickly produce realistic objects

- On-demand printing capability

- 100-micron resolution for paper-thin layers

- Create professional-quality, high-resolution prototypes and complex models

- Smooth surface finish requiring no post-processing

- Produce realistic prototypes and models for presentations

- 3.5" color LCD display with rich, onboard user interface for an enhanced user experience

Duodpfx Abjxt Er Ajhsn

- Access your personal library and preview 3D files

- Onboard tools for setup and maintenance of your printer

- MakerBot Replicator Smart Extruder – quick and easy to swap

- Detects filament absence and automatically pauses printing

- Sends realtime reports to MakerBot Desktop and MakerBot Mobile App

- Onboard camera for monitoring prints and sharing on MakerBot Thingiverse or social platforms

- Mobile control supported

This Replicator Z18 is ideal for professionals seeking high-volume, high-precision 3D printing at a significant savings.

Iklan kecil

Nattheim

Nattheim

11.085 km

Pusat permesinan CNC

SCM morbidelliM 400

Hubungi

Kondisi: bekas, Tahun pembuatan: 2016, MORBIDELLI AUTHOR M400 MAIN FEATURES 5-AXIS MACHINING UNIT "PRISMA": TOP-LEVEL QUALITY AND PRODUCTIVITY SOFTWARE XILOG MAESTRO: EXTREMELY SIMPLE PROGRAMMING MATIC WORKTABLE: ONE POSITIONING FOR MULTIPLE OPERATIONS TECHNICAL DATA AUTHOR M400 AXES Working area X-axis (reference side) mm 3,680 Working area Y-axis (max. loadable workpiece on rear stops) mm 1,680 Workpiece passage Z / number of Z axes mm 170 / 1 Workpiece length in pendulum operation mm 1,650 Travel speed X-Y axes Pro-Speed m/min 85 Z-axis speed m/min 30 INSTALLATION Installed power KVA 62÷82 Compressed air requirement NL/min 400 Extraction air requirement m³/h 4,430 Extraction air velocity m/s 25 Extraction port diameter mm 250 GENERAL FEATURES CNC-controlled drilling and milling center in gantry design with workpiece support table, suitable for performing: - Vertical drilling on the panel surface - Horizontal drilling on all four sides of the workpiece - Grooving with disc cutter - General milling operations 3-4-5 axes MACHINE STRUCTURE The base structure is a monolithic construction made of thick-walled steel. It is reinforced by welded reinforcements across the entire machine bed, ensuring extreme stability. The specially designed table form, with a broad base, is key to guaranteeing lasting precision and stability. The machine layout allows the operator an optimal workflow while keeping space requirements to a minimum. The mobile gantry carrier is constructed from a solid monoblock. It is positioned in the X-direction on prismatically ground guides with recirculating ball carriages. The machining unit on this mobile aggregate carrier is also guided on prismatically ground guides and recirculating ball carriages AXIS TRAVEL All axes move on large-section linear prism guides and recirculating ball shoes with a large support surface, ensuring optimal sliding even at maximum speeds and accelerations. The precise and rapid positioning of the moving gantry (X-axis) is achieved by helical rack and pinion. Large-section recirculating ball screws ensure precise positioning of the working unit along the mobile gantry (Y- and Z-axes). MOTORS, DRIVES AND INVERTERS The perfect mechanical dynamics and maximum positioning accuracy are controlled by high-quality drives and brushless motors, dimensioned to allow speeds of up to 90 m/min while maintaining the best finishing quality CONTROL The control unit consists of a numerical controller for milling and drilling machines with the "Xilog Maestro" graphical user interface running on: - Office operating system Windows 7 - 17” color LCD screen - QWERTY keyboard - Swiveling control panel - Machine operation interface with Xilog Maestro software Xilog Maestro Features Programming - Parametric graphical programming - Import of DXF files (2D; geometries "SPLINE", "POLYLINE 3D", line or circle interpolation in three axes, linear in space, spiral interpolation in the selected plane) - Supported programming with graphic and syntax aids for drilling and milling operations - Automatic optimization of drilling operations and tool change cycles - Capability for panel zero-point shifting to execute drilling on inclined or curved panel edges

Dsdpfx Absxnldbsheun

Iklan kecil

Alkmaar

Alkmaar

11.366 km

Mesin pemotong kertas

IechoPK-0705 Plus

Hubungi

Kondisi: baru, Tahun pembuatan: 2025, Fungsionalitas: berfungsi sepenuhnya, The iEcho PK-0705 Plus is a compact, fully automatic digital cutting plotter specifically designed for the graphics industry, packaging development, and advertising technology. It is the ideal solution for small to medium production runs where die-cutting is required without the need for expensive physical dies.

Key Features:

Dsdpfx Aoyf D Egjbhjun

The PK-0705 Plus is an "all-in-one" system capable of cutting, creasing, and kiss-cutting in a single operation. Its digital control eliminates the costs and lead times associated with conventional die tools.

Applications: Labels, folding cartons, personalized packaging, stickers, POP displays, and greeting cards.

Materials: Cardboard, corrugated board (E-flute), PVC sheets, sticker paper, and various plastics.

Automatic Feeding System: Equipped with a vacuum feeder that automatically feeds sheet stacks, enabling productive, unattended operation.

Oscillating Tool (EOT): Unlike basic plotters, the Plus model can precisely cut thicker or more rigid materials (up to 6 mm) using a vibrating knife.

CCD Camera: A high-precision camera system automatically detects registration marks on printed sheets, ensuring cuts align exactly with the print image—even if sheets are fed at a slight angle.

Vacuum Table: Keeps materials securely fixed during cutting to guarantee maximum precision.

Working Area: 750 mm x 530 mm

Max. Material Thickness: Up to 5 mm (depending on tool)

Tool Configuration: Oscillating knife, drag knife, creasing wheel

Efficiency: No setup times for cutting dies—simply load the file and start.

Versatility: One machine for a wide range of materials, from paper to thin rigid foam boards.

Space-Saving: Compact design fits in almost any print shop.

Summary: The iEcho PK-0705 Plus is a true "workhorse" for print shops seeking flexibility in meeting customer requests, while still achieving the precision of an industrial die-cutting machine, especially on short runs.

Iklan kecil

Falkenberg

Falkenberg

10.784 km

SISTEM ROBOT ZEROLABOR / dinding produksi

RANDEK AB, SchwedenZEROLABOR

Hubungi

Kondisi: baru, Tahun pembuatan: 2023, ZEROLABOR ROBOT SYSTEM for Timber Frame Construction

The Randek ZEROLABOR robot system is a production cell where various work processes are carried out fully automatically by robots. The system is flexible and can be configured to customer specifications. The robot cell can be integrated into existing production lines or operate as a standalone unit. The system enables nearly fully automated production of walls, floors, and roofs using timber frame construction.

Automated Processes:

Duodpfxoduub Ue Abhsn

- Panel handling. Panels are retrieved from various stacks using a vacuum suction system and laid onto the timber frame structure according to CAD data. The system is flexible and is capable of handling different panel sizes.

- Fastening of panels by screwing, stapling, and/or nailing.

- Creation of cut-outs for electrical installations, windows, etc.

- The system can process 1, 2, or 3 types of panels.

- Component marking via inkjet printing.

- Gluing

- Waste handling: plasterboard and OSB waste, for example, is deposited in defined locations or directly into designated waste containers as required.

- Effective dust extraction.

- Alignment of the component with the work table.

- Alignment of studs before nailing, ensuring precise positioning of nails/staples into the studs.

Segel kepercayaan

Dealer resmi yang disertifikasi oleh Machineseeker

Iklan kecil

Piła

Piła

10.567 km

Pusat permesinan

Deckel MahoDMC 63V

Kondisi: bekas, Tahun pembuatan: 2003, jam operasional: 18.782 h, Fungsionalitas: berfungsi sepenuhnya, nomor mesin/kendaraan: 2885002273, jarak pergerakan sumbu X: 630 mm, jarak lintasan sumbu Y: 500 mm, jarak gerak sumbu Z: 480 mm, Deckel Maho DMC 63V milling machine. Year of manufacture: 2003. Equipped with Heidenhain iTNC 530 CNC control. Tool magazine for 24 tool holders. Spindle speed: 8,000 rpm, belt-driven. Tool measurement probe included. Material measurement probe reading system installed. Network interface available for file transfer.

Dusdpfev R U Ulex Abhjn

Iklan kecil

Jerman

Jerman

11.248 km

VITAP K3

VITAPK3

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2023, kecepatan spindel (maks.): 3.600 rpm, daya motor spindle: 5.000 W, jumlah sumbu: 3, This 3-axis VITAP K3 CNC woodworking centre was manufactured in 2023. Take advantage of the opportunity to purchase this VITAP K3 CNC woodworking centre. Contact us for further information.

Additional Equipment

- 20" LCD TFT display

- Industrial PC

- WSC user interface with lister, parametric tools, and parametric setup

- Graphical CAD programming TPA EDI32, basic version

- USB port

- Storage of all files

- Macro programming

- DXF file import

- CE compliant

Machine Advantages

Quality advantages:

- Exhibition machine, never used

Technical advantages:

- Feed speed: 25 m/min

- Automatic 4-position tool changer

- Max. horizontal tool Ø: 12 mm

- Max. vertical tool Ø: 35 mm

- Motor: 1.7 kW

- Number of independent vertical spindles: 12 // number of independent horizontal spindles on X-axis: (2+2)

- Max. horizontal drilling depth on X and Y axes: 35 mm // max. vertical drilling depth: 43 mm // number of horizontal drilling spindles on Y-axis: (2+2)

- Electrospindle: 5 kW with ISO30 taper (rpm 12,000–24,000)

- Max. workpiece dimensions: Y 1250 mm, Z 50 mm

- Min. workpiece dimensions: X 270 mm, Y 150 mm, Z 3 mm

Additional Details

Axes: 3 controlled axes (X, Y, Z)

X-axis: DDT feed system

Y-axis: Head travel path

Z-axis: Drilling operations

Optional upgrades (at additional cost):

- Starter tool set

Djdox U Ub Sepfx Abheun

- Tool holder ISO 30 / ER 32

- Lubrication cartridges

- PC with more powerful processor

- Additional pneumatic top pressure

- Free Nesting system

- Barcode scanner

- Postprocessor for MPR files

- TPA office software license

- Front and rear roller support

- Narrow workpiece guides

- Optional clamp opening for 60 mm thickness

- Angle gear options

- CAD design software for furniture production

Iklan kecil

Bosnia dan Herzegovina

Bosnia dan Herzegovina

11.248 km

HAAS UMC-750SS

HAASUMC-750SS

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2021, jarak pergerakan sumbu X: 762 mm, jarak lintasan sumbu Y: 508 mm, jarak gerak sumbu Z: 508 mm, produsen pengendali: HAAS, kecepatan spindel (maks.): 12.000 rpm, daya motor spindle: 22.400 W, jumlah sumbu: 5, This 5-axis HAAS UMC-750SS vertical machining center was manufactured in 2021. Take the opportunity to purchase this HAAS UMC-750SS vertical machining center. Contact us for further information.

Additional Equipment

• Coolant tank – 208 liters with mobile trolley

• Programmable coolant pump (M-code controlled) // Programmable coolant nozzle (P-COOL)

• Safe Run – Crash and overload detection system

• Surge protection in the control cabinet

• Voltage fault detection module (EPFDM)

• Second button for home position

• Remote jog handle with 2m cable (RJH-XL)

• Memory lock key switch

• Scales for rotary axes

• Top cover

Machine Advantages

Technical machine advantages

• Side-mounted tool changer with 30+1 tools

• Wireless Intuitive Probing System (WIPS)

• Broken tool detection (BTD)

Additional Information

Duodsx U Tizspfx Abhen

Media display via M130 (images, videos, PDFs on screen)

Standard machine memory: 1 GB

Control Unit

15" color LCD monitor with USB port

Touchscreen control interface

Ethernet interface

HaasConnect remote monitoring

HaasDrop wireless file transfer

WiFi connectivity

Control

High-speed machining (HSM)

Rigid tapping

Dynamic Work Offset / Tool Center Point Control (DWO/TCPC)

Macro programming, coordinate rotation and scaling

Iklan kecil

Düsseldorf

Düsseldorf

11.270 km

5-sumbu CNC putar kepala gergaji

Cms BrembanaSPRINT 36 OF

Hubungi

Tahun pembuatan: 2022, jam operasional: 1.160 h, Kondisi: sangat baik (bekas), Fungsionalitas: berfungsi sepenuhnya, Unique special coating

TECHNICAL SPECIFICATIONS

Working Area

Work table: 4,200 × 2,000 mm

Extension table: 4,200 × 1,000 mm

Table height: 735 mm

Loading capacity work table: 2,000 kg

Axes

5-axis CNC swivel head saw

X-axis: 4,250 mm (0–54,000 mm/min)

Y-axis: 3,200 mm (0–54,000 mm/min)

Z-axis: 600 mm (0–12,600 mm/min)

C-axis: 540° (+/-270°), max. 9,000°/min

B-axis: +8° to -90°, max. 9,000°/min

Saw Unit

Saw motor: 18.5 kW with 120 Nm torque, 4,500 rpm

Saw blade diameter: min. Ø 350 mm, max. Ø 625 mm

Cutting depth: max. 200 mm (90°), max. 130 mm (45°)

Flange diameter: Ø 213.3 mm

Drive shaft: Ø 50 mm H7

Water pressure: 4 bar

Drives / Guides

Brushless servo drives

Rack and pinion & ball bearing/slide guideways by Bosch Rexroth

Fully automatic central lubrication

Rapid traverse speed up to 54 m/min

Dsdpeyft S Nefx Abhsun

Control

CNC control OSAl OPEN M

Integrated PC with Windows 7

Control of up to 8 interpolated axes

Interface for *.dxf files

Remote maintenance with existing internet connection

Electronic pressing pressure control and automatic tool wear compensation

CAM Software

DDX “SMART SAW” (German)

Laser

Electronic red laser for indicating saw cuts

Mounted on saw blade housing

Used for straight cuts

Control Cabinet / Operator Panel

21.5" TFT display

Keyboard and joysticks

CMS Active user interface

Operator panel mounted to the right of the machine

Machine Data

Connected load: approx. 25 kW at 400 V ±5%, 50 Hz

Noise level: approx. 75 dBA

Weight: approx. 8,000 kg

Machine dimensions: approx. 8,380 × 5,270 × 3,600 mm (W × D × H)

Safety

Complete CE safety equipment

Safety doors, enclosures, and protective grids

Manufactured in accordance with EU Machinery Directive

DESCRIPTION

5-Axis CNC Swivel Head Saw CMS Brembana Sprint 36 OF – Industrial Quality for Natural Stone & Ceramics

For sale is a 5-axis CNC swivel head saw CMS Brembana Sprint 36 OF from a professional production operation.

The machine is designed for precise machining of natural stone, engineered stone, ceramics, fine stoneware, and glass.

Thanks to the powerful 18.5 kW saw unit, full-featured 5-axis swivel head, and OSAl OPEN M CNC control, the machine is ideal for miter cuts, bevel cuts, contours, multiple cuts, and complex workpieces in high-end interior applications.

The solid steel welded construction, high-quality Bosch-Rexroth guideways, and automatic central lubrication ensure high precision, repeatability, and long service life under continuous operation.

Suitable for:

– Natural stone

– Engineered stone

– Ceramics / fine stoneware

– Glass

Highlights:

– 5-axis CNC swivel head saw with large working area

– Work table 4,200 × 2,000 mm plus extension table

– OSAl OPEN M CNC control with DDX “SMART SAW”

– High traverse speeds up to 54 m/min

– Robust industrial design

– Special coating as per order

– CE-compliant safety features

– Inspection possible by arrangement

Condition:

Used, very well maintained, technically flawless, in operation.

Reason for sale:

Strategic realignment of the company.

Price:

€139,000 net

Location:

North Rhine-Westphalia, Germany.

Note:

Sale as viewed. Dismantling and transport by the buyer.

Kami memudahkan pencarian untuk Anda: "file paternoster"

Anda akan menerima penawaran baru melalui email secara langsung dan gratis.

Anda dapat mengakhiri tugas pencarian kapan saja.