Beli Pro Cool bekas (14.857)

Malakoff

Malakoff Mesin pemotong laser

BystronicBySprint Pro 3015

Lambsborn

Lambsborn Gergaji meja geser

StürmerFKS 550-3200 M A PRO

Donauwörth

Donauwörth Van panel

MERCEDES-BENZVito Kasten 119 CDI Pro RWD Lang Autom. AHK Navi

Donauwörth

Donauwörth Van panel

MERCEDES-BENZVito Kasten 119 CDI Pro RWD Lang Autom. AHK Navi

Hagen

Hagen Mesin pemotong plasma

Swift-CutPro 3000

Temukan lebih banyak mesin bekas

Fevziçakmak

Fevziçakmak Pabrik Daur Ulang Kabel

Mizar Recycling Machinery |PRP XL1 - Pro Cable Recycling Line

Hallstadt

Hallstadt Mesin penggilingan

OptimumF3 Pro CNC

Nuland

Nuland Scania R500 NGS 4x2 - Suspensi udara penuh - Transmisi otomatis - Retarder - Euro 6 - Velg Alcoa - I

SCANIAR500 NGS 4x2 - Full Air - Automaat - Retarder - Euro 6 - Alcoa - I Park Cool - 2017 - TUV 08-2026

Nordrhein-Westfalen

Nordrhein-Westfalen Mesin pengukur koordinat

Carl ZeissPro T compact 3D

Tildonk

Tildonk Pelatih

IvecoMagelys Pro / 12.8m / Euro 6 / Full option

Werlte

Werlte Truk tujuan khusus

KroneCool Liner SDR 27 eL4-DS

Crailsheim

Crailsheim Van panel

Mercedes-BenzSprinter 317 CDI Kasten PRO Hochdach Lang ACC

Hirschberg

Hirschberg Van

MERCEDES-BENZCitan 112 CDI Kasten PRO Standard

Salzburg

Salzburg Rautan

YanigavAP280 / AP280G / AP280E Pro

Wasbek

Wasbek Säulenbohrmaschine - KB 32 SFV PRO

KnuthKB 32 SFV PRO

Wasbek

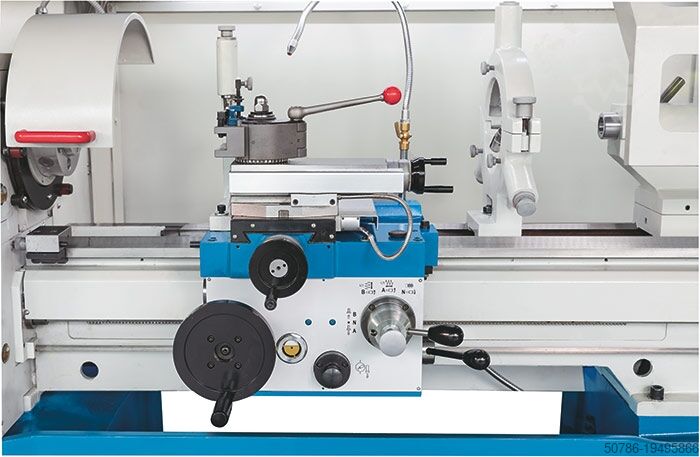

Wasbek Mesin bubut konvensional - V-Turn 410 PRO

KnuthV-Turn 410 PRO

Tildonk

Tildonk Bus pariwisata

IvecoMagelys Pro / 12.8m / Euro 6 / Full option

Obertraubling

Obertraubling Minibus

Mercedes-BenzVito Tourer 114 CDI Pro 4x4 lang 9-Sitze

Obertraubling

Obertraubling Minibus

Mercedes-BenzVito Tourer 114 CDI Pro 4x4 lang 9-Sitze

Jerman

Jerman Vertikal mesin pusat

MIKRONVCE 600 Pro

Cloppenburg

Cloppenburg Van pick-up

IVECODaily 35S18A8P Maxi Air Pro Luftf. / Klima

Wien

Wien PRO-WA2 500-450/320

SCHUMA

Wietmarschen

Wietmarschen Rak kantilever, rak tugas berat untuk barang panjang

ca. 4 lfm. Kragarmregal H: 400cm ,Fuß +3650 kg Belastung pro Arm , Langgutregal

Lüdenscheid

Lüdenscheid Mesin deburring sikat

FLOTTBEM 250 Pro (NEU ab Werk)

Hobro

Hobro