Beli Tepi Tot bekas (1.699)

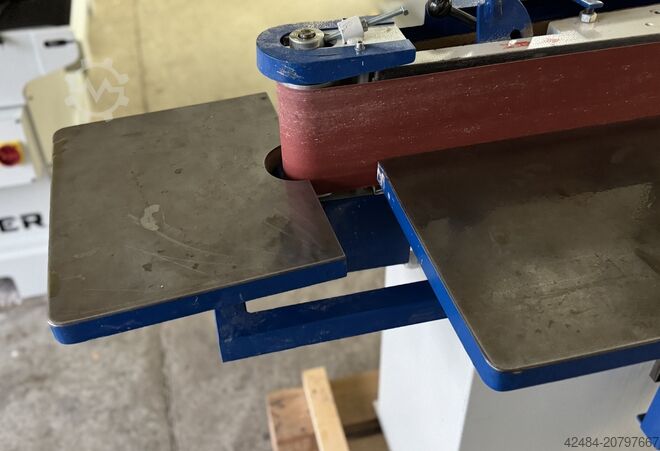

Sierakowska Huta

Sierakowska Huta Mesin penghalus tepi sabuk sudut

ROMA 140

Miechucino

Miechucino Mesin pengikat tepi SCM K 100 pra-penggilingan

SCMK 100

Jerman

Jerman Pita tepi dengan sambungan

Holz-HerStreamer 1057 XL

Egenhofen

Egenhofen Mesin amplas tepi

RehnenJunior R1

Bretzfeld

Bretzfeld Mesin pelapis tepi

HOLZ-HERSTREAMER 1054

Temukan lebih banyak mesin bekas

Bretzfeld

Bretzfeld Mesin pelapis tepi

BIMATICSilence 5 Modell 1802.5

Italia

Italia Mesin pengikat tepi satu sisi

BRANDTHIGHFLEX 1440

Nordheim

Nordheim Mesin pengikat tepi

FELDERG 380-4

Wijchen

Wijchen Mesin Pelapis Tepi SCM Olimpic K400 T-E 2011

SCMOlimpic K400 T-E

Nattheim

Nattheim Mesin pengikat tepi

SüdhofV 20

Nattheim

Nattheim Mesin pengikat tepi

Holz-HerPerfect 1426

Nattheim

Nattheim Mesin pengikat tepi dengan penggabungan

BrandtKD 88 FQ Optimat

Nattheim

Nattheim Mesin pengikat tepi dengan penggabungan

Holz-HerContriga 1366

Nattheim

Nattheim Mesin pengikat tepi

OTTEasymatic

Nattheim

Nattheim Mesin pengikat tepi dengan penggabungan

Brandto KD 69/2 CF

Nattheim

Nattheim Mesin pengikat tepi dengan penggabungan

HebrockAKV 3005 DK - F Airtronic

Nattheim

Nattheim Mesin pengikat tepi

Holz HerUno 1302

Italia

Italia Mesin pengikat tepi satu sisi

BIESSESTREAM B1 7.0

Italia

Italia Mesin pengikat tepi satu sisi

HOMAGKAL 310/10/A3/S2

Italia

Italia Mesin pengikat tepi satu sisi

HOMAGKAL 210 AMBITION 2264

Italia

Italia Mesin pengikat tepi satu sisi

BIESSESTREAM B1 7.0

Wasbek

Wasbek Mesin frais tepi - KF 200

KnuthKF 200

Barntrup

Barntrup Mesin pelapis tepi

IMAADVANTAGE 310

Barntrup

Barntrup Mesin pelapis tepi

GP-ServiceEasyPUR AC25

Nattheim

Nattheim