Beli Michael Relay bekas (680)

Coesfeld

Coesfeld Truk tangki vakum

MERCEDES-BENZSprinter 516 CDI / Rockstroh Drain-Jet 100-2

Raasdorf bei Wien

Raasdorf bei Wien Mesin amplas sabuk lebar

Ott

Edling

Edling Weinig empat sisi mesin penyerut P22N

WeinigP 22 N

Coesfeld

Coesfeld Truk tangki vakum

MANNaaktgeboren VACU PRESS 10.000 TGS 41.440 BB 8X4

Coesfeld

Coesfeld Truk tangki vakum

MERCEDES-BENZSprinter 417 CDI / Leistikow HD-Einbau B55C

Temukan lebih banyak mesin bekas

Sremska Mitrovica

Sremska Mitrovica Mesin meninju otomatis

BSTA 30

Mayen

Mayen Truk pikap bak dump

MERCEDES-BENZSprinter 319*MEILLER*3-SEITEN-KIPPER*

Wiefelstede

Wiefelstede Encoder Unit

KeyenceCA-EN100U

London

London Peralatan sakelar dan papan sakelar

ASCOASCO 7000 Automatic Transfer Switch

Jerman

Jerman Pusat permesinan - horizontal

DMGDMC 80 H

Jerman

Jerman Tekan rem - hidrolik

BYSTRONICP225/410

Nürnberg

Nürnberg Van berpendingin

MERCEDES-BENZSprinter 316 CDI 4x4 3,4m CarrierViento Tiefkühl

Wiefelstede

Wiefelstede Trafo listrik

SiemensAGG5.210

Wiefelstede

Wiefelstede Unit kontrol burner

Landis & StaefaLMG22.130A27

Wiefelstede

Wiefelstede Kontaktor keamanan

Siemens3TK2826-1BB42

Wiefelstede

Wiefelstede Pengatur tekanan

KromschröderGDJ15R04-0

Wiefelstede

Wiefelstede Hubungi blok ekspansi

PilzPZE X4 24VDC 4n/o

Wiefelstede

Wiefelstede Sakelar proteksi tegangan lebih

Phoenix ContactPLT-SEC-T3-24-P

Wiefelstede

Wiefelstede Unit kontrol burner

SatronicDMG 973 Mod.01

Wiefelstede

Wiefelstede Edisi digital

Siemens6ES5 452-8MR11

Wiefelstede

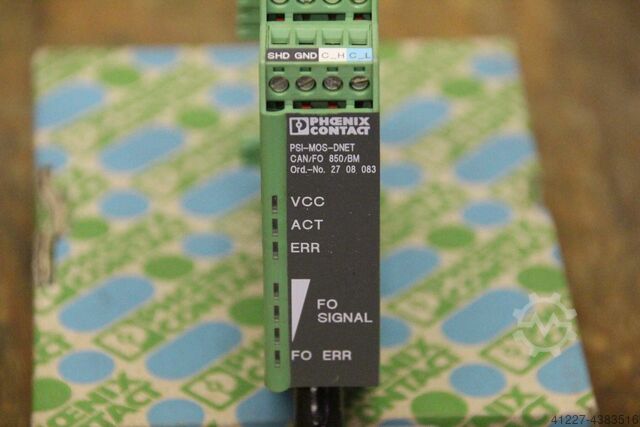

Wiefelstede Konverter FO

Phoenix ContactPSI-MOS-DNET CAN/FO 850/BM

Wiefelstede

Wiefelstede Ganti pemisah

Merlin Gerincompact C630NI

Wiefelstede

Wiefelstede Unit kontrol burner

SatronicDMG 972 Mod.01

Wiefelstede

Wiefelstede Konverter FO

Phoenix ContactFL MC 10/100BASE-T/FO G1300 ST

Wiefelstede

Wiefelstede