Beli Arang Batu Briquetting bekas (881)

Dány

Dány Penggiling batu, penghancur

Lajucso-Print Kft.LAMAL950

Ceggia

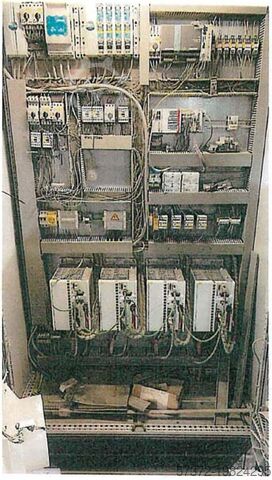

Ceggia Elektroerosion pada batu tufa

AGIE CHARMILLESFORM P 600

Wiefelstede

Wiefelstede Batu gerinda

NilesØ 250

+44 20 806 810 84

Wiefelstede

Wiefelstede Batu gerinda

NilesØ 250

Wiefelstede

Wiefelstede Batu gerinda

NaxosØ 250

Temukan lebih banyak mesin bekas

Jerman

Jerman Pabrik produksi batu

OmagTronic S22 140-90

Neckartailfingen

Neckartailfingen Mesin briket

muetekMPP 280

Neckartailfingen

Neckartailfingen Mesin briket

mütekMPP 180

Neckartailfingen

Neckartailfingen Mesin briket

WEIMATH 600

Neckartailfingen

Neckartailfingen Mesin briket

mütek SystemtechnikMPP 60

Grünkraut

Grünkraut Mesin briket

GROSS Apparatebau GmbHGP 120 Tandem

Borken

Borken Mesin es batu

NordcapSDE 100 l

Wien

Wien Mesin briket

PAWERT-SPM/ Di Più97/I-90/200 // MB100

Bad Honnef

Bad Honnef Kayu - Mesin cetak briket Amis ABP 60 L -Mesin pameran-

AMISHolz - Amis ABP 60 L

Castello di Godego

Castello di Godego Mesin pemotong balok batu pembalut mesin

BretonEASY2WIRE

Castello di Godego

Castello di Godego Mesin sandblasting untuk pelat batu

Breton

Castello di Godego

Castello di Godego Pusat pengolahan kontur batu alam

BretonContourbreton NC160 18

Castello di Godego

Castello di Godego Lini produksi sampel batu pameran

BretonBreton Sample Line

Castello di Godego

Castello di Godego 2 mesin waxing untuk pelat batu

Breton

Castello di Godego

Castello di Godego Mesin pemotong blok batu

BretonPARAGON 2100

Castello di Godego

Castello di Godego Mesin pemotong blok batu

BretonPARAGON FLEX

Turki

Turki Penghancur kerucut / penghancur batu

220-340 t/h cone crusher / stone crusher220-340 t/h cone crusher / stone crusher

Turki

Turki Penghancur kerucut / penghancur batu

300-550TPH Cone crushers / stone crusher300-550TPH Cone crushers / stone crusher

Turki

Turki Penghancur kerucut / penghancur batu

80-340 t/h cone crusher / stone crusher80-340 t/h cone crusher / stone crusher

Turki

Turki Mesin beton - batu

Cement silo | Concrete siloCement silo | Concrete silo

Bekas Arang Batu Briquetting (881)

Sekarang telusuri seluruh Machineseeker dengan lebih dari 200.000 mesin bekas.Jelajahi nama mesin paling populer:

+44 20 806 810 84