Beli Rinser bekas (127)

Urutkan hasil

- Harga terendah Harga tertinggi

- Iklan terbaru Iklan tertua

- Jarak terpendek Jarak maksimum

- Tahun pembuatan terbaru Tahun pembuatan tertua

- Pembaruan terbaru Pembaruan tertua

- Produsen dari A sampai Z Produsen dari Z ke A

- Relevansi

- Harga terendah

- harga

- Harga tertinggi

- harga

- Iklan terbaru

- Tanggal pengaturan

- Iklan tertua

- Tanggal pengaturan

- Jarak terpendek

- jarak

- Jarak maksimum

- jarak

- Tahun pembuatan terbaru

- tahun pembuatan

- Tahun pembuatan tertua

- tahun pembuatan

- Pembaruan terbaru

- pembaruan

- Pembaruan tertua

- pembaruan

- Produsen dari A sampai Z

- pabrikan

- Produsen dari Z ke A

- pabrikan

- Penamaan dari A ke Z

- Penunjukan

- Penamaan dari Z ke A

- Penunjukan

- Model dari A hingga Z

- Model

- Model dari Z ke A

- Model

- Referensi terendah

- referensi

- Referensi tertinggi

- referensi

- Waktu operasional terpendek

- Waktu operasional

- Waktu operasional terpanjang

- Waktu operasional

- relevansi

- relevansi

Lelang

Lelang telah berakhir

Kärnten

Kärnten

10.824 km

Pabrik pembuatan bir + pabrik pengisian

ShandongBrauereianlage

Kondisi: siap digunakan (bekas), Fungsionalitas: berfungsi sepenuhnya, Offered for auction is a complete brewery and bottling line consisting of:

- Brewery installation (including brewhouse, fermentation and storage tanks & additional accessories)

- Bottle filling line

TECHNICAL DETAILS

BREWERY INSTALLATION

Brewhouse

Manufacturer: Shandong

Year of manufacture: 2019

Lhsdpfxswxw U Ns Agljb

Capacity: 20-25 hl

Components: mash tun, lauter tun, wort kettle/boiling kettle, whirlpool

Valves: manual shut-off valves

Wort cooler: 2-stage

Hot water tank: included

Fermentation and Storage Tanks

Fermentation tanks: 6 units of 2,760 l each (CCT tanks)

Year of manufacture: 2019

Insulation: present, with jacket cooling

Operating pressure: 3 bar

CIP capability: yes

Storage tanks: 12 units of 2,760 l each (horizontal tanks)

Year of manufacture: 2019

Operating pressure: 3 bar

Other Components

Malt mill: Shandong, 2019

Steam generator: Yano, Shanghai, 2019, Capacity: 200 kg/h, oil-fired

Cooling units (glycol): 2 units of 28 kW each, 2019

Glycol tank: included

Reverse osmosis system: included

Compressor: JAN, 585 l/min, 2020

KEG Filling

KEG washer: with automatic caustic replenishment & steam heating

KEG filler: up to 70 kegs/h

Control system: Siemens S7

Fitting: Type S (basket fitting)

BOTTLE FILLING LINE

Bottle washer: SEN

Year of manufacture: 1989, overhauled & installed 2020

Capacity: max. 1,500 bottles/h

Isobaric filler block: Shandong Yuesheng, 2019

Stations: 14 rinser, 12 filler, 5 capper stations

Technology: with pre-evacuation & counter-pressure system

Format parts: for 0.33 l longneck & 0.5 l NRW bottles

Drying tunnel: Shandong Yuesheng, 2019

Labeller: with laser printer

Accumulation table: included

Iklan kecil

Freising

Freising

10.981 km

Jalur pengisian untuk botol sekali pakai

Leibinger GmbH

Hubungi

Kondisi: bekas, Tahun pembuatan: 2017, Filling line for 0.33 L disposable Euro bottles\nDescription: Bottles are manually placed onto a bottle feeding table. From there, they are conveyed by a transport belt to the labelling machine, where a wrap-around self-adhesive label is applied. The bottles then proceed to the combined rinser/filler/capper and subsequently to the downstream bottle accumulation table, from which the bottles are manually packed into crates or other containers.\n\nMachine (Additional): Glass bottle filling\nNominal capacity approx.: 3,750 bottles/hour\nFormats: 0.33 L Euro and 0.33 L disposable Vichy bottles\nConveyor direction: left -> right\nOperation / Control system: Filler: Siemens ET 200 SP, touch panel\nConfiguration / Position: free-standing\nEquipment: Bottle feeding table, Intrex labelling machine (Model: Intrex Set with wrap-around adhesive labelling), Leibinger GmbH bottle rinser/filler (Rinser model: 12 BG, Filler model: Multima L [long-tube filler], control: Siemens S7, year of manufacture 2019), bottle accumulation table, bottle transport

Lhsdjwgi Dxspfx Aglsb

Iklan kecil

Freising

Freising

10.981 km

Jalur pengisian PET

KHS

Hubungi

Kondisi: bekas, Tahun pembuatan: 2001, PET bottling line by KHS

Ljdjvu Tufopfx Aglohb

Additional equipment: with depalletizing and palletizing

Output with 1 liter: 24,000 bottles/hour

Formats: 0.5 L and 1 L PET bottles

Features: depalletizer, air conveyor, rinser, filler incl. height inspection, mixer, packer, crate washer, palletizer

Informasi sekarang

+44 20 806 810 84

+44 20 806 810 84

Pasang iklan sekarang

*per iklan/bulan

Iklan kecil

Freising

Freising

10.981 km

Pabrik pengisian botol kaca

Diverse

Hubungi

Kondisi: bekas, Hot filling glass bottle line for smoothies. Comprising the following components:

- Unpacking table

- Bottle rinser

- Vacuum filler (with 24 filling valves, Nagema, 1984, type "VW 24/1")

- Flash pasteurizer (KZE)

- Pressure tank

- Capper (Marchesini, type "ML667")

Lhodpfx Ajwgc R Ejglob

- Cap sorter

- Tunnel cooler

- Blower

- Cap inspection (BBull CIS)

- Labeller (Anker, 1999, type "Roland 10/4")

- Packing table

- Conveyors

- Control panel

- Cooling tower

- Steam boiler

Machine (additional information): Hot filling with pasteurization

Capacity: 5,000 bottles per hour

Formats: 0.25 litre bottles, twist-off caps

Equipment: Unpacking table, rinser, vacuum filler, flash pasteurizer, pressure tank, capper, cap sorter, tunnel cooler, cap blower, cap inspection, labeller, packing table, conveyors, control panel, cooling tower, steam boiler.

Iklan kecil

Menslage

Menslage

11.162 km

Framax RFC-09/08/1-C 2K A/P Pengisi atmosfer

FramaxAtmosphärischer Füller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2012, Overview

The filler was manufactured in 2012 by the Italian producer Framax. The filler comes with a Framax labelling machine. Both machines have been serviced regularly and are already dismantled. Personal inspection of the machines is possible.

Technical Details

Capacity: 1,800 bottles/hour (max. 2,200 bottles/hour)

Processed format: 0.33 L

Closure type: crown cap

Filling Monoblock | Framax | RFC-09/08/1-C 2K A/P | 2012

- Rinser positions: 9

- Filler positions: 8

- Capper positions: 1

- Suitable for natural beer

- Valve type: EVO2 (15 mm)

- Max. bottle diameter: 115 mm

- Min./max. bottle height: 200 mm / 350 mm

Lhjdpfx Asrlf Tqogljb

- Dimensions:

- Length: 4,500 mm

- Width: 1,250 mm

- Height: 2,500 mm

Self-adhesive Labeller | Framax | LLACRSQ VAR STEP 3

- Label positions: front, back, neck

- Dimensions:

- Length: 2,700 mm

- Width: 1,200 mm

- Height: 1,700 mm

Temukan lebih banyak mesin bekas

Iklan kecil

Menslage

Menslage

11.162 km

Pengisi tekanan GAI 4033RE-HP (2022)

GAIDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2022, Overview

The GAI filler was manufactured in 2022 by the Italian company GAI. This machine is used for filling sparkling wine into cylindrical bottles ranging from 0.2L to 1.5L. It is equipped with a rinser (air or water), 16 spouts, 24 electropneumatic filling valves, and 3 capping turrets (each with 3 capping heads). Each capping turret has its own system for feeding and supplying closures. A cork dedusting system is installed. The machine features an integrated overpressure hood with pre-filters and absolute filters. It is sold complete with an automatic CIP system and two Win&tech pallet microfiltration units. The machine is still in operation and available for inspection. Its condition is as new, having only 200 operating hours.

Technical Data

Working direction: left to right

Capacity:

- 0.187 L – 4,500 bottles per hour at 4°C & 15°C

- 0.375 L – 4,500 bottles per hour at 4°C & 15°C

- 0.750 L – 4,000 bottles per hour at 4°C & 2,900 bottles per hour at 15°C

- 1.5 L – 2,000 bottles per hour at 4°C & 1,500 bottles per hour at 15°C

Currently set up for:

Glass bottles: 0.187 L, 0.375 L, 0.750 L, 1.5 L

Closures/Corks:

- Natural corks (boucheuse liège)

- Screw caps

- Decorative closures (champagne style)

Lhedpev Aag Djfx Aglsb

Including CIP system and wine filtration.

Iklan kecil

Menslage

Menslage

11.162 km

Variojet, pengisi vakum prontomatis

Krones - SensometicVakuumfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 1999, Overview

The vacuum filler 'Sensometic' was manufactured by Krones in 1999. The package also includes a rinser, an Alcoa capper, and an integrated cold glue labelling machine. The equipment can be inspected at any time.

Technical Specifications

- Capacity:

- 12,000 bottles/hour with 0.7l glass bottles

- 10,000 bottles/hour with 1.0l glass bottles

- 6,000 bottles/hour with 1.5l PET bottles

- Formats:

Lhsdsukkvnopfx Aglob

- 0.7l glass bottle

- 1.0l glass bottle

- 1.5l PET bottle

- Closures:

- Plastic screw cap, 28 mm

- Press-on cap

- Labelling:

- Body, back, neck loop, neck ring

- Products Filled:

- Raspberry and various fruit syrups

- Special 'Hesperides' vinegar

- Filling temperature: 25°C

- Conveyor direction: left to right

- Siemens S5 controller

Scope of supply

- Rinser | Krones | Variojet | 3-channel rinser; steam, sterile water, air

- Vacuum filler | Krones | Sensometic

- Capper | Alcoa | PP 10 / 360

- Capper | Alcoa | K 10 / 360

- Cold glue labeller | Krones | Prontomatic

Iklan kecil

Menslage

Menslage

11.162 km

KHS monoblok pengisi tekanan (1999)

KHSDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 1999, Overview: This KHS filling monoblock was manufactured in 1999. It remains in production until the end of October and can be inspected in person. A special feature of the filler is its micro-dosing unit, which allows it to process carbonated or still mineral water with natural flavors. An accumulation table is also included.

Technical Data: Rinser, Isobaric Filler, Capper Monoblock | KHS, Zalkin | VK-E 40/50/10/S PET | 1999 (low operating hours)

- Filling of carbonated mineral water and carbonated mineral water with natural flavors

- Format: PET bottles 1.25L & 0.50L, cylindrical petaloid base

- Bottle neck: PCO28 1881

- Current capacity: 23,400 bph

- Number of rinsing nozzles (KHS Innoclean): 40

Lodpfx Agswvl Dgjljhb

- Number of filling valves (KHS Innofill): 50

- Number of capping stations (Zalkin): 16

- Also includes Perrier micro-dosing unit for natural flavors

- With cap magazine & elevator

- Accumulation table Gebo Sidel Type AQ file

- Dynamic accumulation and buffering between the filler outlet and the labeling machine inlet, prevents untimely stoppages before the machine (filler, blow molder) caused by the labeling machine

Iklan kecil

Menslage

Menslage

11.162 km

Botol kaca sekali pakai Proyek AE PROFILL2000 (2020)

Project AEEinweg-Glasflaschen

Hubungi

Kondisi: bekas, Tahun pembuatan: 2020, Übersicht

This complete bottling line was most recently used for filling spirits and includes a rinser-filler combination with T-cork capper, conveyor belts, carton erector, and carton sealer. The line achieves a maximum output of 2,000 bottles per hour, depending on bottle volume and product. As production volumes have increased, the seller has acquired a new line with higher capacity. To present the system in good condition, the seller has installed it in the warehouse.

Technical Details

- Output: 2,000 bottles/hour

Ljdpowqpkaefx Agljhb

- Various bottle shapes possible, as height and width are adjustable

- Bottle volumes from 0.5L to 3.0L are possible

- Most recently used for: spirits, can also be used for other liquids

Scope of Supply

- Project AE PRORINS2000 linear rinser, speed up to 2,000 bph (2020)

- Project AE PROFILL2000 linear filler with 10 electronically controlled valves (2021)

- Borelli T-cork capper

- Conveyor belts

- Lantech C-300 carton erector (2021)

- Lantech CS-300 carton sealer (2021)

Iklan kecil

Menslage

Menslage

11.162 km

SIPA, Procomac Falterbaum, Lini pengisian Profipack untuk PET (sekali pakai) (2000)

SIPA, ProcomacAbfülllinie für PET (Einweg)

Hubungi

Kondisi: bekas, Tahun pembuatan: 2000, Overview This complete PET bottling line was manufactured between 2000 and 2012 by renowned European manufacturers. The line is suitable for still and carbonated soft drinks and includes a stretch blow molding machine with compressed air generator, rinser/filler/capper, labeller, packer, palletizer, wrapper, conveyor belts, inspection systems, mixing and CIP unit. The system achieves an output of up to 8,000 bottles per hour at 1.5 l and is immediately available. All machines are well maintained and equipped with original components and corresponding peripheral devices.

Technical Data

Capacity: 8,000 bottles/h at 1.5 l

Formats: 0.5 l and 1.5 l bottles

Product to be filled: Water and carbonated soft drinks

Closure system: Plastic screw caps, sport caps

Packaging: Shrink packaging: 3x2 formation for 0.5 l and 1.5 l PET bottles

Pallet types: Euro pallet (1,200 x 800 mm), Düsseldorf pallet (600 x 800 mm)

Scope of Supply

Stretch blow molding machine: SIPA, year 2002

Compressed air generator: Kaeser, year 2002

Rinser/filler/capper: Procomac, year 2000

Number of spray nozzles: 24

Number of filling valves: 24

Number of capping heads: 6

Labelling machine: Futura, year 2000

For wrap-around labelling with hot glue

Inspection unit: Logics & Controls, year 2000

For checking fill level, closure, and label

Shrink packer: Krones TFS Variopack, year 2001

Handle applicator: Twinpack, year 2001

Tray labelling machine: Logopack, year 2001

Pallet stretch wrapper: Born, year 2001

Palletizer: Levanti / Profipack

CIP system: Corosys, year 2012

CO2 degassing unit: Corosys, year 2012

Ledpswq Sfgefx Aglehb

Iklan kecil

Menslage

Menslage

11.162 km

Nissei ASB Moretto - SMI (2003)

Nissei ASBKosme - GyM- SMI

Hubungi

Kondisi: bekas, Tahun pembuatan: 2003, en-001

Lodpfx Agjtuyq Ajlehb

Iklan kecil

Menslage

Menslage

11.162 km

Pengisi tekanan KOSME Cosmoblock C (2003)

KOSMEDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2003, Overview

This rinser-filler-capper block was manufactured by Kosme in 2003. The block is designed for filling carbonated and non-carbonated beverages into PET bottles. It comprises a rinser with 2 channels, a pressure filler, and a capper for plastic screw caps. The machine is currently available for immediate delivery.

Technical Data

Output: 10,000 bottles per hour

Formats: 1.0 L PET bottles, 0.5 L PET bottles, 0.33 L PET bottles

Direction of travel: Clockwise

Rinser Specifications:

- 36 rinsing stations

- 2-channel rinser

- Rinsing pipes made of stainless steel

Filling System:

- Isobaric system

Lhsdpfxowiy Tvo Aglob

- 36 filling valves

Capping System:

- Manufacturer: Arol

- 9 capping heads

- With 2 cap chutes, 1 for 28 mm plastic caps, 1 for sports caps

Dimensions: approx. 4,100 x 3,000 x 4,000 mm

Scope of Delivery

Rinser, filler, capper in triblock design

Vacuum barrier system

CIP sleeves made of stainless steel

Cap feeding system

Iklan kecil

Menslage

Menslage

11.162 km

KOSME KSB 4RG (2016)

KOSMEKosme - GyM- SMI

Hubungi

Kondisi: bekas, Tahun pembuatan: 2016, Overview: The complete bottling line for large PET bottles is located in a mineral water plant and was used for filling water. The line has been regularly maintained and is in excellent condition. Capacity: 3,000 bottles/h

List of Machines

- Blow Molding Machine | Kosme | KSB4RG 2016 | 3,600 bottles/h

Lsdpfx Aotuyq Rjglohb

- Air Conveyor | NTS | 2016

- Rinser - Filler - Capper Monoblock | GyM | MONOBLOC 12/3 PVG | 1995 | 3,000 bph

- Cap Feeding Hopper | GyM | 1995

- Handle Applicator | TAS | VA-1150/75C | 2009 | 3,000 bph

- Handle Applicator | And&OR | 50SIA5000R8P2-TL | 2009 | 3,000 bph

- Labelling Machine | Auxiemba | Gacela R-16/8-HM-12 | 2010 | 4,100 bph

- Batch Coder | MACSA | K-1030PLUS | 2008

- Bottle Inverter / Rotator | GyM | 2001

- Divider | SMI | DIVIPACK 2000 | 2002

- Shrink Packer | SMI | LSK 30F | 2002 | 7,200 bph (30 packs per minute, 2*2 on 2.5L / 2 on 5L)

Iklan kecil

Menslage

Menslage

11.162 km

Sidel, Krones Gangloff, Ocme, lini pengisian Robopac untuk PET (sekali pakai) (2013)

Sidel, KronesAbfülllinie für PET (Einweg)

Hubungi

Kondisi: bekas, Tahun pembuatan: 2013, overview-This complete bottling line consists of the machines listed below. It was decommissioned in 2024 and is immediately available. Due to regular maintenance and several upgrades, even the older machines in this line are in good technical condition, and spare parts supply is ensured.

details-PET line up to 30,000 bph in 1.5 L. Neck 29/25

Line comprising:

- Preform rinser Krones, 2016

- Blower Sidel, 2002

- Filling machine Gangloff Scoma, 2013

- Capper, 2013

- Caps Sidel, 2013

Lhedjvuqtlspfx Aglsb

- Inspector Heuft, 2001

- CIP Sovotec, 2011

- Pallet conveyor, 2013

- Inspector Krones, 2013

- Labeller Krones, 2006

- Bottle coder Domino, 2014

- Shrinkwrap packaging machine Ocme, 2013

- Handle applicator Twinpack, 2012

- Conveyors NTS, 1997 / overhauled 2012

- Bottle conveyor Gebo, 1997 / overhauled 2012

- Accumulation table, 2013

- Palletizer Ocme, 2014

- Packaging labeller, 2011

- Packaging labeller 2, 2011

- Package conveyor and divider SES, 2003

- Film Aetna, 2014

- Film Aetna, 2014

- Pack lift Ambaflex, 2013

Iklan kecil

Menslage

Menslage

11.162 km

SIDEL SBO 18, pengisi tekanan Monoblok KHS (1999)

SIDELDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 1999, Overview

This SIDEL blow molding machine and the KHS filling monoblock were both manufactured in 1999. They will remain in production until the end of October and are available for personal inspection. A special feature of the filler is its micro-dosing unit, which allows it to process carbonated or still mineral water with natural flavors. The filler (KHS Innofill monobloc) and the accumulation table (Sidel AQ) are also available separately, without the blow molder (Sidel SBO 18 Series 2); pricing available upon request.

Technical Specifications

Stretch Blow Molding Machine | SIDEL | SBO 18 Series 2 | 1999

- Current capacity: 23,400 bph in 1.25L

- Operating hours: 40,000

- Number of molds: 18

- Mold type: Shell-type quick-change

- Formats produced: 1.25L bottles, cylindrical petaloid base

- Oven type: Sidel

- Neck finish customization: PCO 1881

- Preform type: with recycled PET resin

- The machine has been regularly maintained

- Machine equipped with:

- Sidel preform tipper

- Sidel hopper with cover and feed

- Sidel preform destacker

- Feed rail for Sidel preforms

- Blow-off station for 18 molds

- Sidel control cabinet with Siemens Sidel PCC drive & control

- Lanfranchi bottle buffer silo

- Agitation and air conveyor system with drive to infeed

KHS Monoblock

- Supplied with all available format and spare parts

- Rinsing unit, isobarometric filler, capper

- Monobloc | KHS, Zalkin | VK-E 40/50/10/S PET | 1999 (low operating hours)

- Filling of carbonated mineral water and also carbonated mineral water with natural flavors

- Processing: PET bottles 1.25L & 0.50L cylindrical petaloid base

- Bottle neck: PCO28 1881

- Current capacity: 23,400 bph

- Number of rinsing nozzles (KHS Innoclean): 40

- Number of filling valves (KHS Innofill): 50

- Number of capping stations (Zalkin): 16

- Including micro-dosing system Perrier for natural flavors

- With cap magazine & elevator

Lsdpfx Asrqar Seglohb

Accumulation Table

- Gebo Sidel Type AQ file

- Dynamic accumulation and buffering between filler discharge and labeler infeed, prevents unexpected stops in front of the machine (filler, blow molder) caused by the labeler

Iklan kecil

Menslage

Menslage

11.162 km

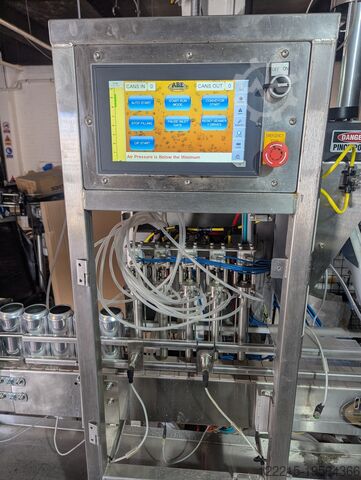

ABE / Vigo UK CraftCan35 Mesin Pengisi Atmosferik (2017)

ABE / Vigo UKAtmosphärischer Füller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2017, Overview This can filling line, model CraftCan35, was manufactured in 2017 by the British company Vigo UK (ABE). The machine has been overhauled, is currently cleaned, disassembled, and securely stored, and is available immediately. It is especially suitable for small to medium-sized breweries looking to process 330 ml and 440 ml standard cans (202 ends). An inspection can be arranged by appointment.

Technical Details

Capacity: up to approx. 35 cans per minute (depending on product)

Formats: 330 ml & 440 ml standard cans (202)

Filling system: 6-head filler

Seaming: Double seam seamer for 202 ends

Voltage / power supply: not specified

Special features: Retrofitted rinser and dryer (Vigo UK)

Pneumatics converted to metric fittings

Original operating manual included

Scope of Supply

1 × Can filling line | ABE | CraftCan35 | 2017

Including retrofitted rinser and dryer

Optional: Stainless steel pack-out table and 3 m single-lane conveyor

Lhsdpswzb Irefx Aglob

Some acrylic safety guards (partial replacement required)

Iklan kecil

Menslage

Menslage

11.162 km

GAI 5003 Pengisi vakum (1998)

GAIVakuumfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 1998, Overview

This vacuum filler was manufactured in 1998 by the Italian company GAI. In 2024, the machine underwent a complete overhaul and is now immediately available.

Technical Details

- Effective output: approx. 4,500-5,000 bottles/hour

Ljdpfx Agouch Tmelehb

- The machine is equipped for the following bottle formats: Bordeaux 75cl (diameter 78mm), Burgundy 75cl, 37.5cl, and Magnums

- Rinser with 20 positions, inspected

- Filler with 20 valves and vacuum system (new turbine) – valves inspected, new seals. New disc springs.

- AROL Saturno capper with 4 heads and vacuum – nearly new jaws in perfect condition – new vacuum pump and circuit

- New wine inlet solenoid valve

- Connector for feed pump

- Machine newly overhauled (solenoid valve, jaws, vacuum turbine, seals, vacuum pump)

- Electrical connection: 400 Volt / 50 Hz, 3-phase

- Dimensions: Length 380cm x Width 140cm x Height 250cm

- Weight: 3,500 kg

Iklan kecil

Menslage

Menslage

11.162 km

KHS Blomax 16C, Innofill, dll. Lini pengisian PET aseptik (2005)

KHSAseptische PET-Abfülllinie

Hubungi

Kondisi: bekas, Tahun pembuatan: 2005, Overview This aseptic PET bottling line for fruit juices, juice-based drinks, and spritzers was manufactured between 2005 and 2006 by the German company KHS. It is suitable for still and carbonated products (up to 5 g/l CO₂) – with or without fruit pulp. The line covers all process steps from blow molding, filling, labeling, and packaging to palletizing and is designed for bottle sizes ranging from 0.5 l to 1.5 l with various closure types. The nominal capacity is approx. 27,000 bottles per hour for 1.0 l still product. The plant will remain in operation until around February/March 2026 and can be inspected upon arrangement. Technical Specifications Capacity: Up to 27,000 bph at 1.0 l still Bottle sizes: 0.5 l – 1.5 l PET Products: Still drinks, carbonated up to 5 g/l, with or without fruit pulp Closures / Neck finish: 26/22, 38 mm flat cap, sports cap possible Year of construction of main machines: 2005–2006, some components newer (e.g. servo capper 2023, labeller 2013, wrapper 2017) Scope of supply Stretch blow moulder KHS Blomax 16C (2005–2006), incl. chilling unit from Riedel Rinser KHS bottle rinser FR-DR (ACF) 140 28/38 Filler KHS Innofill DNVF-PET ACF 100/15 SV, 100 filling valves, 15 capping stations, servo capper (2023) Nitrogen dropper by VBS, sterile tank, filler management KHS Metec Closure feeding system Eckel & Sohn, closure disinfection KHS Innoclean KR9 (flat cap) and SC4 Twin 28 S 04 (sports cap) Cleanroom Cleanroom incl. ventilation system by M&W, Zander/Smardt OPK Conveying technology Bottle and air conveyors KHS, Lanfranchi Inspection Full bottle inspection Heuft Squeezer Labeling Krones Starmodul (year 2013) with Contiroll + 2x AutoCol units + Krones Linadry dryer Label inspection system Heuft FinalView Packaging Tray/shrink packer KHS Kisters Innopack TSP 050 V TPFO Wrap around packer KHS Kisters Innopack 320/70 (year 1999) Carry handle applicator KHS Carry Strip Master CSM 050-2 Palletizing & Wrapping Palletizer KHS Innopal Markant 1BSH2-PL + Innopal Markant 1BSH2/1-PL (both year 1999) Wrapper Haloila Octopus 1845S (year 2017, currently at another location)

Lhedewzlb Nepfx Aglob

Iklan kecil

Radom

Radom

10.280 km

Lini pengisian anggur lengkap

Hubungi

Kondisi: sangat baik (bekas), Fungsionalitas: berfungsi sepenuhnya, Halo,\nSaya menawarkan untuk dijual satu lini lengkap pengisian anggur. Paket lini ini terdiri dari elemen-elemen berikut:\n· Pengisi dengan mesin pelabel PALLADINI, mesin pengisian dilengkapi sistem nitrogenisasi setelah pengisian\n· Mesin pita cukai ENOLMAC S70/3\n· Kompresor Kaeser\n· Filter lilin BILEK\n· Flowmeter dengan pompa\n· Pembilas botol\n· Pompa dengan filter ROVER\n· Dua tangki stainless steel 1100L dan 400L\n· Meja penampung dari baja tahan karat\nHarga: 36.000 EUR (netto) + faktur PPN.\nPenawaran mencakup pemasangan dan commissioning di wilayah nasional.\nDi luar negeri, akomodasi teknisi menjadi tanggungan pembeli.

Lhjdpow Rccbsfx Aglob

Iklan kecil

Czerwionka-Leszczyny

Czerwionka-Leszczyny

10.463 km

Mesin pengolah minuman

Canning line for beer 10000 cph

Hubungi

Kondisi: sangat baik (bekas), Tahun pembuatan: 2021, Fungsionalitas: berfungsi sepenuhnya, Komplette Dosenabfülllinie für Bier (Standarddosen 330 und 500 ml): 10.000 Dosen pro Stunde (500 ml), vollständig optimiert und kalibriert. Nur 4 Bediener/Mitarbeiter im Abfüllprozess erforderlich. Das Angebot umfasst: Depalettierer, Ausspülmaschine, Füller, Verschließmaschine (Seamer), RTG-Füllstandskontrolle, Trockner, Kartoniermaschine, Palettierer, CIP-Anlage, Kurzzeiterhitzung (Flash-Pasteurisierung) Padovan, HGB, Kältemaschine (Chiller), Kompressor usw.

Ljdjuq Sb Sspfx Aglohb

Iklan kecil

Berlin

Berlin

10.804 km

Garis pembotolan

Kettner / Krones / Schneider

Hubungi

Tahun pembuatan: 1991, Kondisi: siap digunakan (bekas), The bottling line includes the following components: (1) Empty bottle unloader Kettner Presant Super, year of manufacture: 1990; (2) Rinser Krones Gripstar, year of manufacture: 1991; (3) Filler Krones FKVCF 110, year of manufacture: 1991; (4) Natural corker Bertolaso Delta 416S, year of manufacture: 1991; (5) Cork conveyor; (6) Wire-hooder Kematec Dratomat 20, year of manufacture: 1991; (7) Depalletizer Schneider EPA 211, year of manufacture: 1991; (8) Depalletizer Schneider EPA 505, year of manufacture: 1991; (9) Capsule applicator Robino Zenith 2-32 Otticoo, year of manufacture: 1991; (10) Labelling machine Krones Solomatik 20-8-4, year of manufacture: 1982; (11) Packer Kettner Robot BE3/CT, year of manufacture: 1990; (12) Paternoster for carton transport; (13) 2x Carton erector Kettner KAF 2400 F, year of manufacture: 1996; (14) Capper Kettner HD 2500, year of manufacture: 1990; (15) Palletizer Kettner Pressant Universal, year of manufacture: 1990; (16) Strapping machine Born HB R 240/430, year of manufacture: 1990; (17) Pallet roller conveyor; (18) Conveyor line, output capacity: 18,000 bottles/hour, with documentation, suitable for sparkling wine bottles. The line has been out of operation for ten years.

Lhodpfek Nm Nrox Agljb

Segel kepercayaan

Dealer resmi yang disertifikasi oleh Machineseeker

Iklan kecil

Hamburg

Hamburg

11.005 km

Pabrik pembotolan air

AMTECWF 1800 RFC

Hubungi

Kondisi: baru, Tahun pembuatan: 2025, Automatic water filling system for up to 300 cycles per minute. Includes a feeding system for empty bottles into the 40-head rotary rinsing unit. Rotary filling station (40 heads) with gravity filling system. The capping unit is equipped with 12 capping heads and is suitable for 28mm and 30mm standard PE caps. All parts in contact with the product are made of SS304 or food-grade plastic. The frame is made of high-quality Q235 hardened steel (optionally SS304). MITSUBISHI PLC, WEINVIEW touchscreen.

Specifications: Maximum machine output (idle): 300 cycles/minute; Number of rinsing heads: 40; Number of filling heads: 40; Number of capping heads: 12; Bottle volume: 350-2000 ml; Bottle diameter: 50-90mm; Bottle height: 150-310mm; Filling tolerance: +/- 2%; Compressed air: 0.5m³/6 bar; Filling water: 9m³/h; Rinse water: 3m³/h; Power: 380V, 7.5kW; Machine dimensions: L4300 x W3400 x H3050mm; Weight: 12,000kg.

Ljdpfov Nlaiox Aglehb

Please note that our new equipment prices are often below typical used machine prices. Simply contact us and let us know your packaging requirements. – Normally, 30 to 50 different new machines are available ex stock at any time. For custom-built machines, we offer very short delivery times from around three weeks. – All machines are supplied with a full warranty.

Iklan kecil

Hamburg

Hamburg

11.005 km

Sistem pengisian cairan

AMTECSAMPLE-SYS LOWVISC

Hubungi

Kondisi: baru, Tahun pembuatan: 2025, Sample filling system for products with low viscosity (ketchup, jam, sauces, etc.) suitable for bottles, jars, and cans. – Includes container orientation system, bottle/container rinsing unit, viscosity filler (hot filling), and vacuum sealing function. – Specifications: Filling volume 20–1000 ml; bottle sizes: diameter 20–150 mm; cap diameter: 20–70 mm; number of filling heads: 4–12; output: up to 6,000 bottles/containers per hour; filling volume tolerance: +/- 1%; capping rate: >99%; power supply: 380 V, 3.5 kW; compressed air: 0.6 m³, 6 bar. – Please note: these specifications refer to the sample system. Final specifications may vary. Kindly provide your packaging details (container size and shape, filling product, required output, etc.) so we can prepare a complete quotation for you.

Please note that our new machine prices are often below typical used machine prices. Feel free to contact us and share your packaging requirements. – We typically have 30–50 different new machines in stock for immediate delivery. In addition, for custom-made machines, we offer very short delivery times starting from approx. 3 weeks. – All machines are supplied with full warranty.

Lodpfx Agov Nlbmslohb

Iklan kecil

Hamburg

Hamburg

11.005 km

Pabrik pembotolan air

AMTECWF 4000 RFC

Hubungi

Kondisi: baru, Tahun pembuatan: 2025, Automatic water filling system for up to 66 cycles/minute. Includes a feed system for empty bottles into the 18-head rotary rinsing apparatus. Rotary filling station (12 heads) with gravity filling system. The capping unit features 6 capping heads and is suitable for 28 and 30mm PE standard caps. All parts in contact with the product are made of SS304 or food-grade plastic. The frame is constructed from high-quality Q235 carbon steel (optionally SS304). MITSUBISHI PLC, WEINVIEW touchscreen. – Specifications: max. idle machine cycle rate: 66 cycles/minute; number of rinsing heads: 18; number of filling heads: 12; 6 capping heads; bottle volume: 350-2000ml; bottle diameter: 50-90mm; bottle height: 150-310mm; filling tolerance: +/- 2%; compressed air: 0.5m³/6bar; filling water: 1.5m³/h; rinsing water: 0.5m³/h; power: 380V, 3.5kW; machine dimensions: L2700xW1600xH2800mm; weight: 2,500kg.

Ledpfxsv Nlacj Aglohb

Please note that our new equipment prices are often below the typical prices for used machines. Feel free to contact us and let us know your packaging requirements. – We generally have 30-50 different new machines available from stock for immediate delivery. For custom-built machines, we offer very short lead times, starting from approximately 3 weeks. – All machines come with a full warranty.

Iklan kecil

Freinsheim

Freinsheim

11.214 km

Mesin minuman

BertolasoType 63/40/6/6

Hubungi

Kondisi: sangat baik (bekas), Tahun pembuatan: 2006, Fungsionalitas: berfungsi sepenuhnya, es_001

Lhodpou A Imvofx Aglsb

Kami memudahkan pencarian untuk Anda: "rinser"

Anda akan menerima penawaran baru melalui email secara langsung dan gratis.

Anda dapat mengakhiri tugas pencarian kapan saja.

Bekas Rinser (127)

Sekarang telusuri seluruh Machineseeker dengan lebih dari 200.000 mesin bekas.Jelajahi nama mesin paling populer:

Informasi sekarang

+44 20 806 810 84

+44 20 806 810 84

Pasang iklan sekarang

*per iklan/bulan