Beli Rinser bekas (130)

Urutkan hasil

- Harga terendah Harga tertinggi

- Iklan terbaru Iklan tertua

- Jarak terpendek Jarak maksimum

- Tahun pembuatan terbaru Tahun pembuatan tertua

- Pembaruan terbaru Pembaruan tertua

- Produsen dari A sampai Z Produsen dari Z ke A

- Relevansi

- Harga terendah

- harga

- Harga tertinggi

- harga

- Iklan terbaru

- Tanggal pengaturan

- Iklan tertua

- Tanggal pengaturan

- Jarak terpendek

- jarak

- Jarak maksimum

- jarak

- Tahun pembuatan terbaru

- tahun pembuatan

- Tahun pembuatan tertua

- tahun pembuatan

- Pembaruan terbaru

- pembaruan

- Pembaruan tertua

- pembaruan

- Produsen dari A sampai Z

- pabrikan

- Produsen dari Z ke A

- pabrikan

- Penamaan dari A ke Z

- Penunjukan

- Penamaan dari Z ke A

- Penunjukan

- Model dari A hingga Z

- Model

- Model dari Z ke A

- Model

- Referensi terendah

- referensi

- Referensi tertinggi

- referensi

- Waktu operasional terpendek

- Waktu operasional

- Waktu operasional terpanjang

- Waktu operasional

- relevansi

- relevansi

Iklan kecil

Menslage

Menslage

11.162 km

Jalur pengisian EUROSTAR SKILLFILL DPS 24-24-6C untuk botol kaca (sekali pakai) (2014)

EUROSTARAbfülllinie für Glasflaschen (Einweg)

Hubungi

Kondisi: bekas, Tahun pembuatan: 2014, Overview This complete isobaric bottling line was manufactured in 2014 by Italian producer Eurostar and is located in Mexico. The line consists of a triblock unit (rinser, filler, and capper), a self-adhesive labeller, and conveyor belts. It is being sold due to the acquisition of a new, higher-capacity system. The line has already been dismantled. Technical details Output: Max. 6,000 bph Formats: 0.210L, 0.355L, 0.500L glass bottles 26mm metal crown caps Dimensions: Width: 5,300 mm Depth: 2,630 mm Height: 2,860 mm Weight: 8,000 kg POWER SUPPLY: Main power: 460V - 60Hz - 3Ph+N+PE Auxiliary voltage: 24V DC Main motor power: 4 kW Installed power: 9 kW Scope of delivery Triblock (rinser, filler, and capper) Self-adhesive labelling machine with 2 stations Conveyor belts

Nwjdpfx Aovm U Dlebueb

Iklan kecil

Menslage

Menslage

11.162 km

KHS Innofill Abfülllinie für Dosen (2017)

KHSAbfülllinie für Dosen

Hubungi

Kondisi: bekas, Tahun pembuatan: 2017, Overview

This complete can beverage filling line was manufactured in 2017 by the German company KHS. The system is designed for beverage production with a capacity of up to 25,000 cans/hour and is in good condition.

Technical Specifications

Nsdpfxsyb R Sro Abuowb

- Capacity: 25,000 bottles/hour (at 0.5L)

- Products: Carbonated soft drinks and beer

- Can formats: 500ml 211/202

- Closure formats: 211/202

- Packaging formats: Tray with film

- Application: KEG + beer

- Condition: Good technical condition, disassembled

Scope of Supply

- Can depalletizer | LINKER | DPG-500 | 2012

- Can inspection | TransTech | Hysek CanCheck | 2012

- Can conveyor | LINKER / KHS | Conveyor RC | 2012

- Rinser | LINKER / KHS | Triplex Rinser TR | 2012

- Flash pasteurizer | KHS | Innopro 140/14/85 | 2012

- Filler | KHS | Innofill Can DVD | 2017

- Seamer | Ferrum | F08 | 2012

- Lid feeder | NSM | Lidserver A30 | 2017

- Conveyor | KHS | Innoline BTR | 2012

- Fill level inspection | KHS | Innocheck CUB | 2012

- Blow-off unit | Europool | -

- Packaging machine | KHS Kisters | SP0502 | 2012

- Pack conveyor | KHS | Innoline GTR | 2012

- Handle applicator | KHS | CSM 050-2 | 2012

- Packaging machine | KHS | Innopack 035 B2 + FS A-L | 2012 / 2017

- Palletizer | KHS | Innopal PBL1N1 | 2012

- Stretch wrapper | SIAT | MFP | 2017

- Pallet conveyor | KHS | Innoline PTR

Iklan kecil

Menslage

Menslage

11.162 km

SIDEL Sidel, Krones, SIG Simonazzi filling line for glass bottles (non-returnable) (2003)

SIDELAbfülllinie für Glasflaschen (Einweg)

Hubungi

Kondisi: bekas, Tahun pembuatan: 2003, en-001

Nwedpfx Aboyb Tucouob

Informasi sekarang

+44 20 806 810 84

+44 20 806 810 84

Pasang iklan sekarang

*per iklan/bulan

Iklan kecil

Menslage

Menslage

11.162 km

Nissei ASB Moretto - SMI (2003)

Nissei ASBKosme - GyM- SMI

Hubungi

Kondisi: bekas, Tahun pembuatan: 2003, en-001

Nwedpfxotuyq As Abusb

Iklan kecil

Menslage

Menslage

11.162 km

Lini pengisian botol kaca Shandong Yuesheng 14-12-6 (dapat digunakan ulang) (2019)

Shandong YueshengAbfülllinie für Glasflaschen (Mehrweg)

Hubungi

Kondisi: bekas, Tahun pembuatan: 2019, Summary

This returnable glass bottle filling line was installed in 2019 and essentially consists of a bottle washer, rinser/filler/capper block, and a labelling system with a laser printer. The line is available because the previous owner is closing the brewery due to retirement. The filling line was operating flawlessly until the end. The equipment remains installed and connected, and can be inspected in person at any time.

Nodexgfr Nopfx Abuewb

Technical Details

Capacity: max. 1,500 bottles/h (operated at 1,000 bottles/h)

Filled product: Beer

Included formats: 0.33l Longneck, 0.5l NRW

Closure type: Crown cap

Scope of Delivery

- Bottle washer | SEN | 1989 (refurbished and installed in 2020)

- Isobaric filler block | Shandong Yuesheng | 2019

- Rinsing stations: 14

- Filling stations: 12

- Capping stations: 5

- With pre-evacuation

- Counter-pressure filler incl. 2 formats: 0.33l Longneck, 0.5l NRW

- Drying tunnel | Shandong Yuesheng | 2019

- Labeller incl. laser printer

- Collection table

Temukan lebih banyak mesin bekas

Iklan kecil

Menslage

Menslage

11.162 km

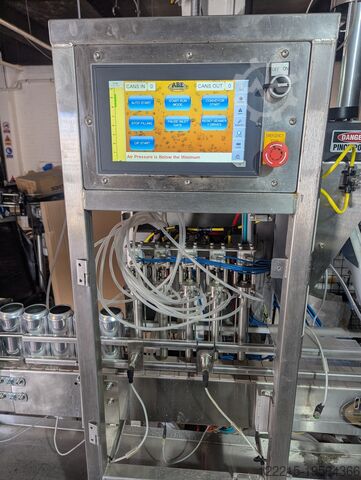

Brewiks, Quantor Mercabrewers,WildGoose, etc. Sudhaus (2018)

Brewiks, QuantorSudhaus

Hubungi

Kondisi: bekas, Tahun pembuatan: 2018, Overview

This complete brewery and cellar plant was manufactured between 2018 and 2021 by several European makers, including Brewiks, Milan Svoboda, Mercabrewers, Wild Goose, Quantor, and others. The system comprises a 5 hL brewhouse from Brewiks, a 12 hL fermentation cellar (6 CCTs), CIP stations, a canning line, labeling and coding equipment, water treatment, air treatment, a glycol chiller, and full malt handling systems – making it a turnkey solution for beer production.

Technical Specifications

Brewhouse (Brewiks 500, 2018)

- Wort output: 5 hL

- Heating: electric, 36 kW

Fermentation Cellar (Svoboda + Mercabrewers, 2018–2021)

- 6 CCTs × 12 hL net capacity

- Design pressure: 3 bar

Nwodpeyb R Iaofx Abueb

CIP Stations (Svoboda CIP 100)

- 2 mobile CIP units

- Tank capacity: 100 L (alkaline + acid)

Filling Line (Wild Goose GOSLING, 2021)

- Semi-automatic

- Formats: 0.33 l / 0.44 l / 0.50 l

Chilling (Quantor Chilly MAX 50L)

- Glycol chiller for CCTs

General Important Information

- Power supply (various units): 230–400 V, 50 Hz

- Applications: brewing, fermentation, can filling

Scope of Supply

- Brewiks Brewhouse (5 hL) | Brewiks | Brewiks 500 | 2018 | Electric heated (36 kW)

- Isobaric CCT | Milan Svoboda | — | 2018 | 12 hL, 3 bar (1/3)

- Isobaric CCT | Milan Svoboda | — | 2018 | 12 hL, 3 bar (2/3)

- Isobaric CCT | Milan Svoboda | — | 2018 | 12 hL, 3 bar (3/3)

- Isobaric CCT | Mercabrewers | — | 2021 | 12 hL, 3 bar (1/3)

- Isobaric CCT | Mercabrewers | — | 2021 | 12 hL, 3 bar (2/3)

- Isobaric CCT | Mercabrewers | — | 2021 | 12 hL, 3 bar (3/3)

- CIP Station | Milan Svoboda | CIP 100 | — | Mobile; 100 L alkaline + 100 L acid (1/2)

- CIP Station | Milan Svoboda | CIP 100 | — | Mobile; 100 L alkaline + 100 L acid (2/2)

- Hop Cannon + Bag Filter | 3M | Series ME 01MET2 | — | 30 L capacity

- Glycol Chiller | Quantor | Chilly MAX 50L | — | Functional, heavily used

- Canning Line | Wild Goose | Quick Change GOSLING | 2021 | Semi-automatic; incl. formats 0.33 / 0.44 / 0.50 L

- Can Rinser + Gravity Feeder | Zomerdijk Engineering | TWIST Rinser | — | For 0.33 / 0.44 / 0.50 L

- Labeller + Printer | EME (Crafted Goose) | Jem-110-S2 | — | Automatic; integrated printer

- Thermal Inkjet Printer | Rynan | R20 (CM220) | — | Batch and date printing

- Air Compressor | ABAC | 50 Hp2 | 2020 | 10 bar; 50 L tank

- Air Dryer | ABAC | COOL21 (CO) | — | 16 bar; 350 L/min

- Reverse Osmosis Unit | AquaControlada | — | — | 2 units (potable & process water)

- Water Tank | ROTH | — | — | 2× 750 L

- Malt Mill | Sommer | Maltman 220 | — | Precision mill

- Sieve Shaker + Sieves | RETSCH | AS200 Basic | — | Complete sieve set for malt analysis

Iklan kecil

Menslage

Menslage

11.162 km

Cimec Monobloc 16-16-1 Abfülllinie für Glasflaschen (Einweg) (2014)

CimecAbfülllinie für Glasflaschen (Einweg)

Hubungi

Kondisi: bekas, Tahun pembuatan: 2014, Overview This complete glass bottling line was manufactured between 2010 and 2014 by several renowned European manufacturers, including CIMEC (Italy). The main unit – a CIMEC 16-16-1 rinsing, filling, and capping monobloc – was built in 2014 and operated in a natural mineral water plant until July 2025. The line also includes additional equipment such as self-adhesive and wrap-around labelers, a DE filter, and a heat shrink tunnel for capsules, making it a fully functional and compact bottling line for glass bottles with crown caps. All equipment remains installed, is in good condition, and can be inspected on site.

Nodjyb Tkdspfx Abuowb

Technical Data Years of manufacture: 2010-2014 Application: water and other beverages Output: approx. 2,000 bottles per hour (330 ml) approx. 1,670 bottles per hour (500 ml) Bottle formats: 250 ml – 1,000 ml (including: 330 ml & 500 ml) Closure type: 26 mm crown cap Configuration (monobloc): 16 rinsing heads 16 filling heads 1 capping head Scope of delivery Rinser / filler / crown capper monobloc | CIMEC | Monobloc 16-16-1 | 2014 | 16/16/1 configuration, 26 mm crown cap, 2,000 bph Self-adhesive labeler | Canellitech | V500 | 2012 | Linear, up to 3,500 bph Wrap-around labeler | Identapply | Servo 125 RH | 2010 | with conveyor belts DE filter | Spadoni | – | 2011 | 80 hl/h Shrink tunnel for capsules | TOSA | TN1 | 2011 | for PVC capsules

Iklan kecil

Menslage

Menslage

11.162 km

Pengisi tekanan KOSME Cosmoblock C (2003)

KOSMEDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2003, Overview

This rinser-filler-capper block was manufactured by Kosme in 2003. The block is designed for filling carbonated and non-carbonated beverages into PET bottles. It comprises a rinser with 2 channels, a pressure filler, and a capper for plastic screw caps. The machine is currently available for immediate delivery.

Technical Data

Output: 10,000 bottles per hour

Formats: 1.0 L PET bottles, 0.5 L PET bottles, 0.33 L PET bottles

Direction of travel: Clockwise

Rinser Specifications:

- 36 rinsing stations

- 2-channel rinser

- Rinsing pipes made of stainless steel

Filling System:

- Isobaric system

Nodpfx Abewiy Tvoujwb

- 36 filling valves

Capping System:

- Manufacturer: Arol

- 9 capping heads

- With 2 cap chutes, 1 for 28 mm plastic caps, 1 for sports caps

Dimensions: approx. 4,100 x 3,000 x 4,000 mm

Scope of Delivery

Rinser, filler, capper in triblock design

Vacuum barrier system

CIP sleeves made of stainless steel

Cap feeding system

Iklan kecil

Menslage

Menslage

11.162 km

KOSME KSB 4RG (2016)

KOSMEKosme - GyM- SMI

Hubungi

Kondisi: bekas, Tahun pembuatan: 2016, Overview: The complete bottling line for large PET bottles is located in a mineral water plant and was used for filling water. The line has been regularly maintained and is in excellent condition. Capacity: 3,000 bottles/h

List of Machines

- Blow Molding Machine | Kosme | KSB4RG 2016 | 3,600 bottles/h

- Air Conveyor | NTS | 2016

- Rinser - Filler - Capper Monoblock | GyM | MONOBLOC 12/3 PVG | 1995 | 3,000 bph

- Cap Feeding Hopper | GyM | 1995

Nwsdjtuyq Rspfx Abuob

- Handle Applicator | TAS | VA-1150/75C | 2009 | 3,000 bph

- Handle Applicator | And&OR | 50SIA5000R8P2-TL | 2009 | 3,000 bph

- Labelling Machine | Auxiemba | Gacela R-16/8-HM-12 | 2010 | 4,100 bph

- Batch Coder | MACSA | K-1030PLUS | 2008

- Bottle Inverter / Rotator | GyM | 2001

- Divider | SMI | DIVIPACK 2000 | 2002

- Shrink Packer | SMI | LSK 30F | 2002 | 7,200 bph (30 packs per minute, 2*2 on 2.5L / 2 on 5L)

Iklan kecil

Menslage

Menslage

11.162 km

Alfatek TBC 24.8.28.4 ISO E.P. H.P mesin pengisi tekanan (2023)

AlfatekDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2023, Overview

This isobaric filling block was manufactured in 2023 by the Italian company Alfatek BP Srl. The machine is a Beer Plus version, featuring an additional 8-head degassing turret before the filler that enables triple pre-evacuation for enhanced bottling performance. After purchase, the machine will be completely overhauled, delivered in as-new condition, and provided with a 12-month warranty. The unit is immediately available.

Technical Data

- Capacity: 6,000 bottles per hour (with 33 cl containers)

- Formats: 33 cl, 50 cl, 75 cl (26 mm and 29 mm crown caps)

- Configuration:

- 24-head rinser

Njdew U Si Sjpfx Abuewb

- 8-head deoxygenation turret

- 28-valve isobaric filler

- 4-head crown capper (Arol)

- Application: Beer and carbonated beverages (e.g. lemonade, soda)

- Mouth finish: 26 mm crown cap, 29 mm crown cap

- Condition: Excellent condition, fully refurbished and delivered with warranty

Scope of Supply

- Complete monoblock including rinser, degassing turret, isobaric filler, and crown capper

- Documentation included

- 12 months warranty post-refurbishment

Iklan kecil

Menslage

Menslage

11.162 km

GAI MLE 661 BIER 003 Druckfüller (2017)

GAIDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2017, Overview This monoblock filling line was manufactured in 2017 by the Italian company GAI. The MLE 661 BIER 003 combines rinsing, isobaric filling, capping, and labeling in a single compact and fully automatic unit. The system also includes an ENOS Compatta labeling machine from the same year. The line is in good condition and immediately available.

Technical Data

Capacity Still Beer: ~750 l/h ≈ 1,000 bottles/h (0.5-l format)

Carbonated Beer: ~525 l/h ≈ 1,200 bph (0.33-l format)

Application: Still and carbonated beer

Bottle sizes: 0.25 l – 1.0 l glass bottles

Closure types: 26-mm and 29-mm crown corks

Rinser heads: 6

Filler heads: 6 (isobaric system)

Capper heads: 1

Construction: Stainless steel frame and sanitary components

Operation: Fully automatic with synchronized control

Njdpeyb S R Nofx Abuewb

Scope of supply

Monoblock (rinser-filler-capper) | GAI | MLE 661 BIER 003 | 2017 | Isobaric filling system, 6-6-1 configuration, glass bottles 0.25–1.0 l, 26-mm and 29-mm crown corks

Labeling machine | ENOS | Compatta | 2017 | Self-adhesive labeling machine, compatible with beer bottles

Iklan kecil

Menslage

Menslage

11.162 km

DUETTI, GAI, ROBINO & GALANDRINO WIN&TECH Einweg-Glasflaschen (2022)

DUETTI, GAI,Einweg-Glasflaschen

Hubungi

Kondisi: bekas, Tahun pembuatan: 2022, Overview This complete isobaric filling line for sparkling wine (Sekt) was manufactured in 2022 by leading Italian producers DUETTI, GAI, ROBINO & GALANDRINO, WIN&TECH, and MAKRO. It is designed for premium sparkling wine in glass bottles and includes depalletizing, rinsing, isobaric filling, capping, wire hooding, capsule application, labeling, CIP, and filtration. The line is still in operation, with approximately 2,100 operating hours, and can be inspected upon request. It will be available at the end of March 2026. Technical Data Application: Sparkling wine (glass bottles) Output: Up to 4,500 bottles/hour Formats and Speeds: 0.187 l: 4,500 bottles/hour (4 °C and 15 °C) 0.375 l: 4,500 bottles/hour (4 °C and 15 °C) 0.750 l: 4,000 bottles/hour (4 °C) / 2,900 bottles/hour (15 °C) 1.500 l: 2,000 bottles/hour (4 °C) / 1,500 bottles/hour (15 °C) Operating Hours: 2,100 Scope of Delivery Depalletizer | DUETTI | M Automatic | 2022 | — Rinser-Filler-Capper Monoblock | GAI | 4033 (16 rinser valves / 24 filling valves / 3×3 capping heads) | 2022 | Isobaric Automatic CIP System | WIN&TECH | — | 2022 | — Microfiltration Units (2 pieces) | WIN&TECH | — | 2022 | — Wire Hooder | ROBINO & GALANDRINO | REKORD 6 | 2022 | — Fill Level and Closure Inspector | CMP | — | 2022 | — Capsule Applicator & Monoblock | ROBINO & GALANDRINO | ZENITH F 3/18 | 2022 | — Self-adhesive Labeler | MAKRO | 4 stations | 2022 | — Bottle Conveyor | — | — | 2022 | Included

Nwsdpfxsyb Tf Is Abusb

Iklan kecil

Menslage

Menslage

11.162 km

SIDEL SBO 18, pengisi tekanan Monoblok KHS (1999)

SIDELDruckfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 1999, Overview

This SIDEL blow molding machine and the KHS filling monoblock were both manufactured in 1999. They will remain in production until the end of October and are available for personal inspection. A special feature of the filler is its micro-dosing unit, which allows it to process carbonated or still mineral water with natural flavors. The filler (KHS Innofill monobloc) and the accumulation table (Sidel AQ) are also available separately, without the blow molder (Sidel SBO 18 Series 2); pricing available upon request.

Technical Specifications

Stretch Blow Molding Machine | SIDEL | SBO 18 Series 2 | 1999

- Current capacity: 23,400 bph in 1.25L

- Operating hours: 40,000

- Number of molds: 18

- Mold type: Shell-type quick-change

- Formats produced: 1.25L bottles, cylindrical petaloid base

- Oven type: Sidel

- Neck finish customization: PCO 1881

- Preform type: with recycled PET resin

- The machine has been regularly maintained

- Machine equipped with:

- Sidel preform tipper

- Sidel hopper with cover and feed

- Sidel preform destacker

- Feed rail for Sidel preforms

- Blow-off station for 18 molds

- Sidel control cabinet with Siemens Sidel PCC drive & control

- Lanfranchi bottle buffer silo

- Agitation and air conveyor system with drive to infeed

KHS Monoblock

- Supplied with all available format and spare parts

- Rinsing unit, isobarometric filler, capper

- Monobloc | KHS, Zalkin | VK-E 40/50/10/S PET | 1999 (low operating hours)

- Filling of carbonated mineral water and also carbonated mineral water with natural flavors

Nodpfx Aborqar Ssuowb

- Processing: PET bottles 1.25L & 0.50L cylindrical petaloid base

- Bottle neck: PCO28 1881

- Current capacity: 23,400 bph

- Number of rinsing nozzles (KHS Innoclean): 40

- Number of filling valves (KHS Innofill): 50

- Number of capping stations (Zalkin): 16

- Including micro-dosing system Perrier for natural flavors

- With cap magazine & elevator

Accumulation Table

- Gebo Sidel Type AQ file

- Dynamic accumulation and buffering between filler discharge and labeler infeed, prevents unexpected stops in front of the machine (filler, blow molder) caused by the labeler

Iklan kecil

Menslage

Menslage

11.162 km

ABE / Vigo UK CraftCan35 Mesin Pengisi Atmosferik (2017)

ABE / Vigo UKAtmosphärischer Füller

Hubungi

Kondisi: bekas, Tahun pembuatan: 2017, Overview This can filling line, model CraftCan35, was manufactured in 2017 by the British company Vigo UK (ABE). The machine has been overhauled, is currently cleaned, disassembled, and securely stored, and is available immediately. It is especially suitable for small to medium-sized breweries looking to process 330 ml and 440 ml standard cans (202 ends). An inspection can be arranged by appointment.

Technical Details

Capacity: up to approx. 35 cans per minute (depending on product)

Formats: 330 ml & 440 ml standard cans (202)

Filling system: 6-head filler

Seaming: Double seam seamer for 202 ends

Voltage / power supply: not specified

Special features: Retrofitted rinser and dryer (Vigo UK)

Pneumatics converted to metric fittings

Njdowzb Iropfx Abujwb

Original operating manual included

Scope of Supply

1 × Can filling line | ABE | CraftCan35 | 2017

Including retrofitted rinser and dryer

Optional: Stainless steel pack-out table and 3 m single-lane conveyor

Some acrylic safety guards (partial replacement required)

Iklan kecil

Menslage

Menslage

11.162 km

KHS Blomax 16C, Innofill, dll. Lini pengisian PET aseptik (2005)

KHSAseptische PET-Abfülllinie

Hubungi

Kondisi: bekas, Tahun pembuatan: 2005, Overview This aseptic PET bottling line for fruit juices, juice-based drinks, and spritzers was manufactured between 2005 and 2006 by the German company KHS. It is suitable for still and carbonated products (up to 5 g/l CO₂) – with or without fruit pulp. The line covers all process steps from blow molding, filling, labeling, and packaging to palletizing and is designed for bottle sizes ranging from 0.5 l to 1.5 l with various closure types. The nominal capacity is approx. 27,000 bottles per hour for 1.0 l still product. The plant will remain in operation until around February/March 2026 and can be inspected upon arrangement. Technical Specifications Capacity: Up to 27,000 bph at 1.0 l still Bottle sizes: 0.5 l – 1.5 l PET Products: Still drinks, carbonated up to 5 g/l, with or without fruit pulp Closures / Neck finish: 26/22, 38 mm flat cap, sports cap possible Year of construction of main machines: 2005–2006, some components newer (e.g. servo capper 2023, labeller 2013, wrapper 2017) Scope of supply Stretch blow moulder KHS Blomax 16C (2005–2006), incl. chilling unit from Riedel Rinser KHS bottle rinser FR-DR (ACF) 140 28/38 Filler KHS Innofill DNVF-PET ACF 100/15 SV, 100 filling valves, 15 capping stations, servo capper (2023) Nitrogen dropper by VBS, sterile tank, filler management KHS Metec Closure feeding system Eckel & Sohn, closure disinfection KHS Innoclean KR9 (flat cap) and SC4 Twin 28 S 04 (sports cap) Cleanroom Cleanroom incl. ventilation system by M&W, Zander/Smardt OPK Conveying technology Bottle and air conveyors KHS, Lanfranchi Inspection Full bottle inspection Heuft Squeezer Labeling Krones Starmodul (year 2013) with Contiroll + 2x AutoCol units + Krones Linadry dryer Label inspection system Heuft FinalView Packaging Tray/shrink packer KHS Kisters Innopack TSP 050 V TPFO Wrap around packer KHS Kisters Innopack 320/70 (year 1999) Carry handle applicator KHS Carry Strip Master CSM 050-2 Palletizing & Wrapping Palletizer KHS Innopal Markant 1BSH2-PL + Innopal Markant 1BSH2/1-PL (both year 1999) Wrapper Haloila Octopus 1845S (year 2017, currently at another location)

Nwjdpfxewzlb Ne Abusb

Iklan kecil

Menslage

Menslage

11.162 km

Lini pengisian PET (sekali pakai) Krones Contiform, Mecafill, Variojet (2002)

KronesAbfülllinie für PET (Einweg)

Hubungi

Kondisi: bekas, Tahun pembuatan: 2002, Overview This PET bottling line was manufactured in 2002 by Krones (Germany). The system is designed for carbonated beverages such as beer or soft drinks and is also suitable for water with or without CO₂. With an output of up to 12,000 bph (0.5 L), it offers a complete solution from bottle blowing to palletizing. The line is being sold due to the modernization of the PET department and its replacement by a higher capacity system. The equipment is in good condition and remains fully functional.

Technical Data

Line capacity:

- 12,000 bph (0.5 L)

- 9,000 bph (1.0 L)

- 8,000 bph (1.5 L)

- 6,000 bph (2.0 L)

Formats: 0.5 L, 1.0 L, 1.5 L, 2.0 L

Neck finish: PCO 1810

Max. bottle diameter: 106 mm

Products: Beer (+4°C), kvass and soft drinks (+10°C), still and carbonated water

Labelling: Wrap-around labels, pre-cut paper labels, hotmelt

Secondary packaging: Film only (4×3 and 3×2)

Pallet type: EURO 1200×800 mm

Control system: Siemens S7-300

Power supply: 400 V, 3PH, 50 Hz, TN-S

Scope of supply

- Blow Moulder | Krones | Contiform S8 | 2002 | incl. preform feed, cooler, crate tipper

- Rinser | Krones | Variojet | 2002 | Rotary machine

- Filler | Krones | Mecafill | 2002 | Rotary, isobaric filler for CSD and beer

- Labeller | Krones | SV 360-10-113 | 2002 | Rotary labeller

- Labeller | Krones | Canmatic 600-10 | 2002 | Rotary labeller, hotmelt

- Packaging Machine | Krones | Variopac FS-45 | 2002 | Shrink wrapping machine, formats 4×3/3×2

- Palletizer | Krones | Pressant Compact 1N | 2002

- Stretch Wrapper | Robopac | Rotoplat | 2002

- Air Conveyor | Krones | Airco S | 2002 | For blown PET bottles

- Bottle Conveyor | Krones | Synco S | 2002 | For filled and labelled bottles

- Packaging Conveyor | Krones | Multico S | 2002 | For product packages

Nsdpfxjxhf Hij Abuowb

- Pallet Conveyor | Krones | — | 2002 | For pallet transport

- Peripheral equipment | Krones | — | 2002 | Cap feeder system, hopper, valve distributor

Iklan kecil

Menslage

Menslage

11.162 km

GAI 5003 Pengisi vakum (1998)

GAIVakuumfüller

Hubungi

Kondisi: bekas, Tahun pembuatan: 1998, Overview

This vacuum filler was manufactured in 1998 by the Italian company GAI. In 2024, the machine underwent a complete overhaul and is now immediately available.

Technical Details

Nodsuch Tmspfx Abuowb

- Effective output: approx. 4,500-5,000 bottles/hour

- The machine is equipped for the following bottle formats: Bordeaux 75cl (diameter 78mm), Burgundy 75cl, 37.5cl, and Magnums

- Rinser with 20 positions, inspected

- Filler with 20 valves and vacuum system (new turbine) – valves inspected, new seals. New disc springs.

- AROL Saturno capper with 4 heads and vacuum – nearly new jaws in perfect condition – new vacuum pump and circuit

- New wine inlet solenoid valve

- Connector for feed pump

- Machine newly overhauled (solenoid valve, jaws, vacuum turbine, seals, vacuum pump)

- Electrical connection: 400 Volt / 50 Hz, 3-phase

- Dimensions: Length 380cm x Width 140cm x Height 250cm

- Weight: 3,500 kg

Iklan kecil

Italia

Italia

11.016 km

Mesin Lini Pengisian Botol Bekas

Sidel Bottling LineBottling Glass Line 46.000 bph

Hubungi

Kondisi: bekas, Tahun pembuatan: 2006, Fungsionalitas: berfungsi sepenuhnya, NP 690 – LINEA COMPLETA DI IMBOTTIGLIAMENTO VETRO SIDEL 46.000 bph

Prodotto: Acqua Minerale

Velocità: 46.000 bph

Depallettizzatore Simonazzi

Modello: SWEEP-OFF-B

Anno: 2005

Tipo: con strato

Sistema di rimozione interfalde

Magazzino pallet

Saturatore Simonazzi

Modello: CARBOGEA

Anno: 2005

Velocità: 9.800 lph

Monoblocco di Riempimento Simonazzi

Modello: EUROSTAR 2000

Anno: 2005

Risciacquatrice 84 pinze

Ugello fisso

Tipo di trattamento: Acqua

Riempitrice 84 valvole

Tipo di riempimento: Isobarico

Tipo valvola: Meccanica

2 Tappatori:

- 24 teste tappi corona Ø 26

- 24 teste per tappo a vite in alluminio

Ispezionatrice bottiglie Heuft

Modello: HBBVXTXXX

Anno: 2011

Verifica livello e tappo

Etichettatrice SIMONAZZI

Modello: ALFA TOP BRAIN

Anno: 2005

32 teste

3 stazioni colla a freddo

Tipologia etichette applicabili:

• Fronte

• Retro

• Collarino

Ispezionatrice etichette ABULL

Modello: STRATEC - F300

Nwodpfoyc Rw Djx Abuob

Anno: 2005

Fardellatrice SMI

Modello: SK800F

Anno: 2005

Versione: Lancio film

Tipologia: Solo film

Doppia corsia per fardelli 3x2

Fardellatrice SMI

Modello: SK600P

Anno: 2005

Versione: Lancio film

Tipologia: film e vassoio

20/24 pz (4x6)

Pallettizzatore SIMONAZZI

Modello: KOMBİ

Anno: 2005

Tipo: sistema a spinta

Sistema interfalde

Magazzino pallet

Fasciapallet ROBOPAC

Modello: ROTARY

Anno: 2005

Tipo di fasciatura: braccio rotante

Nastri trasportatori bottiglie

Nastri trasportatori fardelli

Iklan kecil

Freising

Freising

10.981 km

Rins-, Füll- und Verschließmaschine

KHS

Hubungi

Tahun pembuatan: 2001, Kondisi: bekas, Combined rinser and filler for 0.5 l, 1.0 l, and 1.5 l PET bottles. Capacity: 24,000 bottles/h. The rinser is equipped with a chlorine dioxide dosing unit and a sterile water supply. The filler comes with a screw cap applicator. Fill quantity control is achieved via flow measurement. Liquid nitrogen dosing is possible via a mobile unit.

Machine (additional info): PET bottle disinfection and filling system

Capacity: 24,000 bph

Formats: 0.5 l, 1.0 l, and 1.5 l PET bottles

Operating direction: left -> right

Operation / Control: Touch panel / Simatic S7

Material: predominantly stainless steel

Installation / Position: free-standing

Equipment: stainless steel enclosure, upward-opening Plexiglas safety guard; 70 rinse valves on the rinser; 80 filling valves; fill quantity detection via IDM; Alcoa 28 mm Bericap capper; Prominent chlorine dioxide dosing system; sterile water filtration unit; mobile liquid nitrogen dosing; pneumatic screw cap feed (approx. 25 m); 2 basements for a total of 3 mesh box pallets.

Nedpox T Andofx Abuowb

Iklan kecil

London

London

11.722 km

Mesin produksi minuman

KHSINNOFILL DVD 40

Hubungi

Kondisi: sangat baik (bekas), Tahun pembuatan: 2015, de

Nodstraaaspfx Abuowb

Iklan kecil

Milano

Milano

11.226 km

Lini pengisian kaleng KHS untuk minuman berkarbonasi dan bir

KHSCAN FILLING LINE FOR CSD AND BEER

Hubungi

Kondisi: hampir baru (bekas), Tahun pembuatan: 2012, Fungsionalitas: berfungsi sepenuhnya, LINEA DI RIEMPIMENTO LATTINE KHS PER CSD E BIRRA

Dati Tecnici

Capacità: 25.000 lattine/ora (su 0,5L)

Nsdpox U Snpofx Abuewb

Prodotti riempiti: bevande analcoliche gassate e birra

Formati lattina: 500ml 211/202

Formati tappo: 211/202

Formati di confezionamento: vassoio con film termoretraibile

Applicazione: CSD + birra

Condizione: buone condizioni tecniche, smontata

Fornitura compresa

Depallettizzatore lattine sfuse | LINKER | DPG-500 | 2012

Ispezione lattine | TransTech | Hysek CanCheck | 2012

Trasportatore lattine | LINKER / KHS | Conveyor RC | 2012

Risciacquatrice | LINKER / KHS | Triplex Rinser TR | 2012

Pastorizzatore flash | KHS | Innopro 140/14/85 | 2012

Riempitrice | KHS | Innofill Can DVD | 2017

Aggraffatrice | Ferrum | F08 | 2012

Alimentatore coperchi | NSM | Lidserver A30 | 2017

Nastri trasportatori | KHS | Innoline BTR | 2012

Controllo livello riempimento | KHS | Innocheck CUB | 2012

Soffiaggio | Europool | –

Imballatrice | KHS Kisters | SP0502 | 2012

Trasportatore confezioni | KHS | Innoline GTR | 2012

Applicazione maniglie | KHS | CSM 050-2 | 2012

Imballatrice | KHS | Innopack 035 B2 + FS A-L | 2012 / 2017

Pallettizzatore | KHS | Innopal PBL1N1 | 2012

Fasciapallet | SIAT | MFP | 2017

Trasportatore pallet | KHS | Innoline PTR

Segel kepercayaan

Dealer resmi yang disertifikasi oleh Machineseeker

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Mengisi Monoblok

CimecLD 16-16-3E/PK-1RF-1V

Hubungi

Kondisi: bekas, Tahun pembuatan: 2010, Technische Daten & Leistungsmerkmale

Dieser Pentablock-Füller-Monoblock vereint Spülstation, Füller, Verkorker und Agraffen-Verschließer in einem kompakten, rotierenden Rahmengestell zur Glasflaschenverarbeitung. Gefertigt von Mondial, bietet die Ausführung LD 16-16-3E/PK-1RF-1V eine robuste mechanische Bauweise mit präziser Flaschenführung in allen Turmstationen (Spülung, Füllung, Verschluss, Agraffieren). Das Modell eignet sich für den Second-Hand-Bereich und den Einbau in gebrauchte Abfüllanlagen für Getränkeproduktion und industrielle Verpackung.

Modell: LD 16-16-3E/PK-1RF-1V

Verarbeitbare Flaschen: Glas

Formatgrößen: Kompatibel mit 0,33L und 0,75L Flaschen

Spülerturm: 16 Greifer (rotierend)

Füllerturm: 16 Ventile, Gravitation/leichte Vakuumtechnik

Nsdpjx Ivq Iofx Abuewb

Mögliche Verschlüsse: Kronkorken, Sektkorken (Pilzkorken)

Agraffieren: Integrierter Drahtkorbaufsetzer für Sektverschlüsse

Bedienoberfläche: Siemens OP73 Micro

Typische Anwendungen: Wein, Schaumwein, Spezialgetränke in Glasflaschen

Fortschrittliche Automatisierung & Steuerung

Der Monoblock ist mit einer integrierten Automatisierungslösung und einer bedienerfreundlichen HMI zur Rezepturverwaltung, Formatwahl und Fehlerdiagnose ausgestattet. Das Bedienpersonal profitiert von einer klaren Alarmstruktur und geführten Prozessen, die Stillstandzeiten minimieren und den Format- sowie Verschlusstypwechsel vereinfachen. Die Steuerung garantiert synchrone Bewegungsabläufe der Turmstationen für schonende Produktbehandlung und konstant präzisen Füllstand.

Siemens OP73 Micro Touchpanel zur Überwachung und Steuerung

Programmierbare Formatparameter für verschiedene Flaschengrößen

Verriegelte Schutzabdeckungen und Sicherheitssteuerung zum Bedienerschutz

Schnelle Formatanpassung für Flaschenhöhe und Wechselstern

Produktionslinien-Integration

Die Maschine kann als Einzelmaschine oder eingebunden in komplette gebrauchte Abfülllinien betrieben werden. Sie ist vorbereitet für Anbindung an Zu- und Abtransportbänder und ermöglicht so eine nahtlose Kopplung mit vorgelagerten und nachgelagerten Maschinen wie Etikettierer, Inspektionssystemen oder Packern. Durch die rotary Bauweise können verschiedene Glasflaschenformate und Verschlussarten wirtschaftlich verarbeitet werden – bei dauerhaft schonender Behandlung und gleichbleibendem Durchsatz.

In-line-Integration mit Standardbandanlagen

Mehrformatfähigkeit: 0,33L und 0,75L Glasflaschen

Flexible Verschlussauswahl: Kronkorken und Pilzkorken mit Drahtagraf.

Geeignet für Betriebsumgebungen von refermentiertem Bier und klassisch hergestelltem Sekt

Maschinenzustand & Wartungshistorie

Die Maschine wird als sofort betriebsbereit angeboten und adressiert Kunden, die zuverlässige gebrauchte Abfülltechnik suchen. Alle relevanten Wartungspunkte sind frei zugänglich, mit klar definierten Vorgehen für planmäßige Inspektionen und Reinigung, um kontinuierlich hohe Produktqualität zu sichern.

Betriebsstatus: sofort einsetzbar

Einfache Zugänglichkeit für Inspektion und Reinigung

Unterstützt Reinigung/Sterilisation aller produktberührenden Teile

Leistung & Vielseitigkeit

Dieser Monoblock ist speziell für Glasgetränke-Abfüllungen mit höchsten Anforderungen an Spülung, exakte Gravitäts-/Vakuumabfüllung, sicheren Verschlussauftrag und stabile Drahtagrafierung für Sekt- und Schaumweinabschlüsse konzipiert.

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Garis pembotolan lengkap

Hubungi

Kondisi: bekas, jam operasional: 30.000 h, de

Nwsdpfex H Tilsx Abueb

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Mesin Cetak Tiup

KronesS8

Hubungi

Kondisi: bekas, Tahun pembuatan: 2004, de

Nodpfx Aox H Tf Tebuowb

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Mengisi Monoblok

BertolasoSyncronia 16-16-1-840

Hubungi

Kondisi: bekas, Tahun pembuatan: 2000, Technische Daten & Leistungsmerkmale

Der Bertolaso Füllmonoblock Syncronia 16-16-1-840 ist eine gebrauchte Abfüllanlage für hochwertige Getränkeabfüllung in Glasflaschen. Diese gebrauchte Komponente der Abfülllinie integriert Rinser, Füller und Verschließer in einem kompakten Rotationssystem, das für zuverlässige, industrielle Verpackungsprozesse konzipiert wurde. Hergestellt von Bertolaso, verfügt die Maschine über ein Inertgas-Managementsystem für die Flaschenkonditionierung sowie den Verschluss und eignet sich ideal für Premiumprodukte mit hohem Anspruch an Sauerstoffreduktion.

Hersteller: Bertolaso

Modell: Syncronia 16-16-1-840

Baujahr: 2000

Gebindeart: Glasflaschen

Rinser: 16 Greifer mit Eindringdüse und doppelter Inertgasbehandlung

Füller: Gravitation/leichter Unterdruck mit Stickstoffunterstützung

Verschließer: Einkopf-Korkverschließer mit Inertgas- und Vakuumverkorkung

Formate: Kompatibel mit 0,375 l und 0,75 l Flaschenformaten

Elektrik: 400 V, 50 Hz

CIP-Bereitschaft: Integriertes CIP-System mit Edelstahl-Blendflaschen

Modellcode & Konfiguration: Syncronia 16-16-1-840

Fortschrittliche Automations- & Steuerungssysteme

Nwsdpfsx E Snkjx Abujb

Der Monoblock bietet prozessoptimierende Features zur Sicherstellung konstanter Qualität und minimierter Sauerstoffaufnahme. Der Rinser arbeitet mit doppelter Inertgasbehandlung zur Vorkonditionierung der Flaschen. Der Füller arbeitet im leichten Vakuum-/Gravitationsbetrieb mit Stickstoff, ergänzt durch Füllstandskontrolle an der Füllventilebene. Ein Sensor am Auslauf erkennt hängende Flaschen und schützt so den Produktfluss, wodurch Stillstandszeiten minimiert werden. Integriertes CIP und Edelstahl-Blendflaschen ermöglichen effiziente Reinigung-in-Place-Prozesse sowohl am Rinser als auch am Füller und unterstützen einen hygienischen Produktionsbetrieb.

Integration in Abfülllinien

Für industrielle Verpackungsanwendungen entwickelt, kann dieser Monoblock als Einzelaggregat oder eingebunden in eine komplette gebrauchte Abfülllinie betrieben werden. Die Maschine ist für Glasflaschen optimiert und kann mit Fördertechnik upstream sowie Inspektions- oder Etikettiersystemen downstream verbunden werden. Die Formatflexibilität umfasst 0,375-l- und 0,75-l-Flaschen, und ein schneller Formatwechsel wird durch das Turret-Design und entsprechende Formatteile unterstützt.

Maschinenzustand & Wartungshistorie

Die Maschine befindet sich in ausgezeichnetem Allgemeinzustand und hat im Laufe ihres Betriebs etwa 1.000.000 Flaschen verarbeitet. Der Zustand und das integrierte CIP-System sprechen für eine sorgfältige Nutzung und Wartung, daher eignet sie sich ideal für Betriebe, die abfüllbereite Anlagen mit nachgewiesener Zuverlässigkeit suchen.

Leistung & vielseitiger Einsatz

Diese Monoblock-Anlage eignet sich besonders für sauerstoffempfindliche Produkte in Glasflaschen. Die doppelte Inertgas-Ausspülung, stickstoffgestützte Füllung im leichten Unterdruck sowie Vakuumverkorkung mit Inertgaseinblasung sichern perfektes Sauerstoffmanagement. Die von Bertolaso entwickelte Technik steht für präzise Abfüllung, produktschonende Handhabung und zuverlässigen Verschluss mit geraden Korken.

Kami memudahkan pencarian untuk Anda: "rinser"

Anda akan menerima penawaran baru melalui email secara langsung dan gratis.

Anda dapat mengakhiri tugas pencarian kapan saja.

Bekas Rinser (130)

Sekarang telusuri seluruh Machineseeker dengan lebih dari 200.000 mesin bekas.Jelajahi nama mesin paling populer:

Informasi sekarang

+44 20 806 810 84

+44 20 806 810 84

Pasang iklan sekarang

*per iklan/bulan