Beli Sterilizer bekas (202)

Urutkan hasil

- Harga terendah Harga tertinggi

- Iklan terbaru Iklan tertua

- Jarak terpendek Jarak maksimum

- Tahun pembuatan terbaru Tahun pembuatan tertua

- Pembaruan terbaru Pembaruan tertua

- Produsen dari A sampai Z Produsen dari Z ke A

- Relevansi

- Harga terendah

- harga

- Harga tertinggi

- harga

- Iklan terbaru

- Tanggal pengaturan

- Iklan tertua

- Tanggal pengaturan

- Jarak terpendek

- jarak

- Jarak maksimum

- jarak

- Tahun pembuatan terbaru

- tahun pembuatan

- Tahun pembuatan tertua

- tahun pembuatan

- Pembaruan terbaru

- pembaruan

- Pembaruan tertua

- pembaruan

- Produsen dari A sampai Z

- pabrikan

- Produsen dari Z ke A

- pabrikan

- Penamaan dari A ke Z

- Penunjukan

- Penamaan dari Z ke A

- Penunjukan

- Model dari A hingga Z

- Model

- Model dari Z ke A

- Model

- Referensi terendah

- referensi

- Referensi tertinggi

- referensi

- Waktu operasional terpendek

- Waktu operasional

- Waktu operasional terpanjang

- Waktu operasional

- relevansi

- relevansi

Iklan kecil

Newton Aycliffe

Newton Aycliffe

11.700 km

24.000 unit/jam lini pengisian vial produksi Steriline dengan perlengkapan tambahan

STERILINEVFM400

Hubungi

Kondisi: bekas, Unused and never installed Steriline vial filling line, manufactured in 2021, with a capacity of up to 24,000 vials per hour.

Ffedpfxoyhc Sqs Abhju

The line is designed to operate within a closed oRABS (Open Restricted Access Barrier System) environment and is currently configured to fill 6R (5 ml) and 2R (2 ml) vials, sealed with lyophilization/injection stoppers or aluminum caps. (The manufacturer can supply format parts for different vial and stopper sizes upon request.)

The line comprises the following equipment:

Main equipment included in the line:

- RC-V8 rotary washing machine

- ST9-CCS depyrogenation tunnel

- Tray loader / TL2

- 4 LAF (laminar air flow) units

- VFM400 vial filling machine + oRABS

- SWB1 belt conveyor + oRABS

- PDS positive dividing system + oRABS

- VCM400 vial capping machine + oRABS

- SWB2 belt conveyor

- LBT belt conveyor

- SWB3 belt conveyor

- RT rotary table

Additional equipment included in the line:

- 2 Fedegari FOF4/9 autoclaves

- Veolia Waters Orion 6000 E WPU water purification system

- Steris Finn Aqua pure steam generator

- Steris Finn Aqua multi-effect water distiller

- Atlas Copco ZT37VSD WP air compressor

- 15,000-liter WFI (Water for Injection) storage tank

- 6,000-liter WPU (Water for Pharmaceutical Use) storage tank

- Main control cabinet

- 2 Certuss steam generators

- 2 Permak economizers and pumps

- WPU and WFI water distribution system (distribution system devices: pipes, valves, pumps, etc.)

- Cleanroom panels and ceilings

- Daikin chiller unit

Full project specifications available with installation.

Iklan kecil

Budapest

Budapest

10.450 km

Sterilisasi UV

P SelectaU.V. Esteril

Hubungi

Kondisi: baik (bekas), Guter Betriebszustand. Bitte sehen Sie sich auch unsere anderen Angebote an.

Fodjqmiwaopfx Abhefu

Iklan kecil

Duxford

Duxford

11.686 km

Oven Sterilisasi Ehret STE 1610/2/100

EhretSTE 1610/2/100

Hubungi

Tahun pembuatan: 2002, Kondisi: bekas, de

Ffjdpfx Aoxhflxebhju

Informasi sekarang

+44 20 806 810 84

+44 20 806 810 84

Pasang iklan sekarang

*per iklan/bulan

Iklan kecil

Lorquí

Lorquí

12.252 km

FMC-JBT Sterilmatic penanak kontinu

JBTSTERILMATIC

Hubungi

Kondisi: bekas, Fungsionalitas: berfungsi sepenuhnya, Los autoclaves se utilizan para la esterilización de productos envasados que requieren alcanzar altas temperaturas (+100ºC) para la eliminación o inactivación de microorganismos patógenos.

Autoclaves continuos: Se integran dentro de las líneas de producción. En ellas, los envases ingresan de manera automática y salen en el extremo opuesto ya esterilizados, lo que permite alcanzar volúmenes de producción mucho más altos.

Ffedpfswxwzpox Abhju

- Cocedor-enfriador rotativo FMC-JBT: Constan de dos o más cuerpos donde se lleva a cabo cada fase de la esterilización.

Dimensiones:

Módulo 1: 9 m x 2 m x 2,30 m.

Módulo 2: 9 m x 1,55 m x 2,30 m.

Módulo 3: 13 m x 2,10 m x 2,30 m.

Iklan kecil

Freising

Freising

10.981 km

Tanah diatom dan filter sterilisasi

Schenk Filterbau

Hubungi

Kondisi: bekas, Combination filter (diatomaceous earth and sterile filter) for beer filtration with hydraulic compression, equipped with 100 x 100 cm filter plates and external riser pipes.

Machine (type): Combination filter

Capacity: 120 hl/h

Plate size: 100 cm edge length

Length: 7000 mm

Width: 1500 mm

Height: 1500 mm

Orientation/Position: horizontal

Base construction: mounted on a steel frame, standing on feet

Equipment: 31 diatomaceous earth layers (32 frames), 50 sterile filtration layers, 4 pressure gauges (10 bar), 6 lanterns, riser pipes, diatomaceous earth discharge screw (Allweiler), original wort content measurement, flow measurement, 3 x turbidity measurement (inlet, KG filter outlet, EK filter outlet).

Fsdpfx Abevcqlwohofu

Spare parts: 295 gasket rings for filter plates, 3 support plates for diatomaceous earth filter.

Temukan lebih banyak mesin bekas

Iklan kecil

Lorquí

Lorquí

12.252 km

ROSSI&CATELLI MULTITUBULAR ASEP STERILIS

ROSSI & CATELLIOLIMPIC

Hubungi

Kondisi: sangat baik (bekas), Fungsionalitas: berfungsi sepenuhnya, La planta de esterilización Olimpic TC destaca por su alto rendimiento y máxima fiabilidad, diseñada específicamente para procesar productos de mayor consistencia y viscosidad.

Fedpfx Abewn Hbkohsfu

Productos: kétchup, salsas, mermeladas, tomate, etc.

Viscosidad: alta viscosidad.

El esterilizador aséptico multitubular Rossi & Catelli Olympic es un sistema de intercambio térmico continuo destinado a la esterilización de productos alimenticios líquidos y semilíquidos como zumos, concentrados, purés, salsas y productos con pequeñas partículas en suspensión. Utiliza un sistema de tubos concéntricos o paralelos para calentar rápidamente el producto a altas temperaturas (HTST/UHT), seguido de un enfriamiento controlado, garantizando la preservación de las propiedades organolépticas y nutricionales del producto.

INCLUYE:

* 13 tubos de mantenimiento de temperatura, total: 65 tubos.

* Sistema CIP de limpieza con 1 depósito de ácido cítrico y 1 depósito de ácido ascórbico con agitador: 1,15 m de diámetro x 1,90 m de alto

* Bomba dosificadora doble: 0,80 m x 0,50 m x 0,90 m

* Intercambiador de calor tubular SPIRAX ARC

* Bomba de recirculación de agua caliente

* Conjunto de válvulas: 1,90 m x 1 m x 1,90 m

* 2 caudalímetros con cuadro eléctrico: 1 m x 0,77 m x 2 m

La producción puede variar dependiendo del producto.

Iklan kecil

Ukraina

Ukraina

11.094 km

Lini aseptik bekas untuk Tetra Pak - 3600 botol/jam

SOCO System

Hubungi

Kondisi: bekas, Tahun pembuatan: 2006, jam operasional: 18.625 h, nomor mesin/kendaraan: LC598, Technical specifications & performance data

This complete Tetra Fino Aseptic line is an integrated aseptic packaging solution developed by Tetra Pak for liquid food applications. The core filling machine was manufactured in 2006 and is complemented by downstream packaging equipment. Designed for industrial packaging and beverage production, it offers reliable second-hand performance with hygienic processing and efficient material flow management.

Production speed: up to 3,600 packs/hour

Container type: carton-based aseptic packages (Tetra Fino Aseptic family)

Supported volumes: 0.2 L to 1.0 L (examples: 0.2 L, 1.0 L)

Currently processed main product: Milk

Main filler year of construction: 2006

Additional module: SOCO System unit, year of manufacture 2014

Accessories: Cart trolley with roll holder, ABC valve, 1 m chain conveyor

Advanced automation & control systems

The line includes an industrial control panel for centralized operation of filling and downstream handling. The aseptic filler integrates automated process sequences for sterilization, filling, and sealing under controlled conditions. Operator safety interlocks and machine guarding support safe operation, while standardized HMI navigation simplifies recipe selection and format changes. The architecture is designed for quick restarts and consistent availability in demanding environments.

Line integration capability

This used filling line is configured for in-line operation, connecting the aseptic filler with conveyors and a SOCO System packaging module. It supports the integration of typical auxiliary units such as product discharge systems, cap or straw applicators, and end-of-line packaging machines. Format changes allow for multiple carton volumes in the 0.2 L to 1.0 L range, providing multi-product flexibility for milk and juice production. The conveyor arrangement ensures gentle product transfer and balanced accumulation between stations.

Machine condition & maintenance history

The equipment is reported as currently in production and in overall good condition. Continuous operation with milk indicates stable performance and consistent hygienic compliance. The 2006 filler and 2014 downstream module are maintained to preserve aseptic integrity and packaging quality, making this used industrial line a strong candidate for quick recommissioning.

Operational performance & versatility

Optimized for liquid foods, the line supports aseptic packaging of products such as milk and juices in the Tetra Fino Aseptic pillow format. Key benefits include extended shelf life at ambient temperatures without preservatives, multi-layer high-barrier materials, and hermetic sealing. The layout provides reliable filling accuracy, gentle product handling, and consistent quality, suitable for beverage production requiring long shelf life and stable logistics.

Installation requirements & site preparation

The syst...

Ffsdpfx Asyh E Apjbhou

Iklan kecil

Misterton

Misterton

11.699 km

Autoklaf

MMM GroupVakulab HL

Hubungi

Kondisi: baik (bekas), de

Fedpfx Aboyifqvshjfu

Iklan kecil

Britania Raya

Britania Raya

11.700 km

Alfa Laval BTPX 205SGD-34CDP-50 klarifier sentrifugal baja tahan karat

ALFA LAVALBTPX 205SGD-34CDP-50

Hubungi

Kondisi: bekas, Klarifier sentrifugal bekas Alfa Laval model BTPX 205SGD-34CDP-50 berbahan stainless steel. Sistem skid mounted dengan fasilitas sterilisasi uap. Penggerak langsung menggunakan motor 6,5 kW 415V 3/50 2900 rpm. Kecepatan maksimal mangkuk 9650 rpm. Termasuk beberapa alat.

Ffedoyh I Uuepfx Abhou

Iklan kecil

Swiss

Swiss

11.094 km

Lini pengisian aseptik bekas SIPA GEA untuk susu dengan kapasitas hingga 48.000 botol...

AERZEN

Hubungi

Kondisi: bekas, Tahun pembuatan: 2018, jam operasional: 900 h, nomor mesin/kendaraan: LC524, Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph

Ffjdpfx Aeyhcivobheu

GEA ASEPTIC BLOW-FILL SYSTEM ABF 2.0

Fully aseptic blow molding, filling, and capping system with H2O2-based preform sterilization.

Introduction to the SIPA GEA Aseptic Filling Line for Milk up to 48,000 bph

The SIPA GEA aseptic filling line for milk, capable of handling up to 48,000 bottles per hour, provides a highly efficient and technologically advanced solution for the packaging industry. Specifically, this system utilizes machinery from 2018 to ensure high quality standards and food safety. It processes milk in 235 ml bottles with plastic screw caps and a 38 mm neck finish. The line has only 900 operating hours.

SIPA SFR 24 EVO Stretch Blow Molding Machine for the SIPA and GEA Aseptic Line

Manufactured by GEA in 2018, the SIPA SFR 24 EVO blow molding machine produces high-quality bottles from PET preforms. This enables a continuous, uninterrupted production and ensures efficiency. Additionally, the SFR 24 EVO model optimizes energy consumption and ensures precise container forming, making it ideal for high-performance lines such as this used SIPA GEA aseptic filling line for milk up to 48,000 bph.

GEA Filling Machine

The GEA filling machine, also from 2018, serves as the core of the line. Since milk is filled under aseptic conditions, the organoleptic and microbiological characteristics of the product are preserved. Furthermore, the SIPA and GEA aseptic line doses the product accurately and operates reliably, reducing waste and improving overall efficiency. As a result, it increases productivity while meeting stringent hygiene standards.

Arol Capping Machine for Secure Closure

The Arol capping machine, made in 2018, safely applies plastic screw caps to the bottles. It ensures a tight seal and is perfectly sized for the 38 mm neck. Integration into the filling line guarantees fast and consistent capping, prevents leaks, and maintains product integrity.

Aerzen GM25S Compressor

The 2018 Aerzen GM25S compressor powers the blow molding process. It specifically supplies high-quality compressed air required by the machine to shape PET bottles. Its efficiency and reliability significantly contribute to smooth production, playing a crucial role in maintaining high-speed output.

Operational Condition and Limited Use

This used SIPA GEA aseptic filling line for milk up to 48,000 bph has processed only around one hundred production cycles, keeping the machinery in excellent condition. Limited use ensures optimal performance and minimal wear, making this system virtually as good as new in terms of operation. Well-maintained components also extend machine lifetime and reduce the need for costly spare parts.

Line Efficiency and Performance

The used SIPA GEA aseptic filling line f...

Iklan kecil

Nikaragua

Nikaragua

11.094 km

Ruang persiapan susu UHT bekas Tetra Pak 4000 L/jam

Hubungi

Kondisi: bekas, Tahun pembuatan: 2006, nomor mesin/kendaraan: LC562, Used UHT Milk Preparation Room Tetra Pak 4000 L/h

Operating Capacity and Product Versatility

The used UHT milk preparation room Tetra Pak 4000 L/h provides optimized aseptic thermal processing for dairy and beverage applications. Specifically, the unit operates with variable flow rates from 2,000 to 4,000 liters per hour, making it suitable for regular milk, flavored milk, drinking yoghurt, and condensed milk. Additionally, with program adjustments, fruit juices, nectars, and soft drinks can also be processed. This flexibility makes it ideal for operations producing multiple products. The facility is currently still in storage and thus ready for relocation and installation in a new production site.

Fjdsyhbudjpfx Abhefu

Aseptic Inline Homogenization

The used UHT milk preparation room Tetra Pak 4000 L/h is equipped with an aseptic homogenizer from Tetra Pak, model Tetra Alex, year 2006. Notably, this unit, installed downstream of the pre-heating stage, operates under sterile conditions to ensure the breakdown of fat globules and uniform distribution of solid and liquid phases. Consequently, it helps maintain the emulsion stability of flavored milk and yoghurt beverages. Furthermore, the aseptic inline design reduces the risk of contamination after thermal processing. As a result, it preserves the physical and chemical consistency of the product across subsequent production stages. The robust construction also simplifies cleaning and routine maintenance.

Clean-in-Place (CIP) System

The line integrates a CIP system (Clean-in-Place), supplied by Gemak in 2009, which consists of four dedicated tanks: nitric acid, caustic soda, hot water, and rinse water. Specifically, the system automatically sanitizes all product-contact surfaces under controlled parameters. It ensures compliance with hygiene standards throughout multiple cleaning phases. Moreover, it manages solution recovery and optimizes water usage across all cleaning cycles. As such, the CIP system in the used milk preparation room Tetra Pak 4000 L/h minimizes downtime and supports continuous production. Most importantly, it safeguards product integrity between production cycles.

Thermal Treatment and Holding Time Regulation

The sterilization process is based on a holding tube supplied by Tetra Pak in 2006, designed to maintain the product at the target temperature for the required period. Combined with a tubular UHT heat exchanger, this coil ensures indirect and uniform thermal processing. The system thereby guarantees precise holding times and optimal microbial reduction. Likewise, the unit preserves its organoleptic properties through consistent heat transfer. Therefore, the used UHT milk preparation room Tetra Pak 4000 L/h offers reliable processing for both dairy and plant-based applications.

Deaeration and Sterile Storage

The system includes a Tetra Pak deaerator from 2006, which removes dissolved oxygen and unwanted gases before the UHT process. Accordingly, it improves product shelf life and minimizes oxidative degradation. Moreover, ...

Iklan kecil

Belanda

Belanda

11.094 km

Tangki aseptik bekas Tetra Pak 2010 - 13.000 liter

Tetra Pak®

Hubungi

Tahun pembuatan: 2010, Kondisi: bekas, nomor mesin/kendaraan: TNK7, en-01

Fjdpfxoyhbm Ts Abhofu

Iklan kecil

Georgia

Georgia

11.094 km

Pengisian lengkap bekas Krones CSD pabrik PET – 22.000 botol/jam

GEA

Hubungi

Kondisi: bekas, Tahun pembuatan: 2010, jam operasional: 47.000 h, nomor mesin/kendaraan: LC582, Used complete Krones CSD PET Bottling Line – 22,000 BPH – Overview

This used, ultra-clean Krones CSD PET bottling line is a highly efficient turnkey solution for beverage production and industrial packaging of carbonated soft drinks, cider, sparkling water, still water, and CO2-mixed juices. Built in 2010 by Krones and GEA and maintained in production with OEM service, the line delivers up to 22,000 bottles per hour (0.5 l) and 18,000 bph (1.5 l), with a Contiform S12M blow molder directly connected to an ultra-clean isobaric filler-capper block. This is a market-ready used filling line designed for reliability, hygiene, and quick changeovers in PET.

Technical Specifications & Performance Data

Manufacturer: Krones and GEA

Year: 2010

Operating Hours: approx. 47,000

Rated Capacity: 22,000 bph (0.5 l) | 18,000 bph (1.5 l)

Processed Products: carbonated soft drinks, cider, sparkling water, still water, CO2-mixed juices

Ffodpfoyhbmtox Abhou

Filling Technology: ultra-clean, isobaric, volumetric PET filling

Current Product: Apple juice with water and CO2

Neck Types: PCO 1810, PSO 28 mm, 1810/1881 short neck

Control: Siemens Simatic S7 PLC platform

Main Equipment Scope

CIP: Krones VarioClean F AUT fully automatic CIP system, 4 x 5000 L, 30 m³/h

Process: GEA TDS plant with flash pasteurizer, mixer, carbonator, deaerator, and process tanks

Preforms: Preform tipper and feed conveyors; Krones Contifeed RS preform feeder; Prejet linear preform cleaning system

Caps: Cassner cap feeder with cap rinsing and sterilization

Blow Molder: Krones Contiform S12M, directly connected to the ultra-clean block (no air conveyor)

Filler-Capper Block: Krones Volumetric VODM-PET 2.160-66-103 with integrated capper; Krones Vario Dos filler block CIP

Coding and Inspection: Domino DDC 3 laser coder; Krones Checkmat 731 FM-X+L fill level inspector; Krones Checkmat 731 EM label inspector

Conveying and Testing: SYNCO bottle conveyors; Krones Flowliner water leakage tester

Labeller: Krones Contiroll OPP 720-15, double-roll wrap-around hot-melt labeller

Secondary Packaging: Krones VarioPro FS shrink tray packer; Krones Multico S pack conveyor; Twin Pack applicator with carry handle

Pack Coding: Leisinger Jet 3 inkjet coder

Palletizing: Krones Robopox Modulpal (2016)

Advanced Automation and Control Systems

Line Control & PLC

Siemens Simatic S7 series PLC for coordinated line control, interlocks and diagnostics

Integrated filling block cleaning via Krones Vario Dos for validated ultra-clean cycles

Recipe and parameter management for fast changeovers between PET formats

Quality Assurance & Traceability

Laser date coding (Domino DDC 3) on primary packaging; inkjet coding (Leisinger Jet 3) on packs

Inline inspection with Krones Checkmat systems for fill level and label presence/position

Leak detection via Krones Flowliner for container integrity

Possibilities for Integrati...

Iklan kecil

Rumania

Rumania

10.001 km

Mesin produksi minuman

GAI3031 FE

Hubungi

Kondisi: hampir baru (bekas), Tahun pembuatan: 2017, jam operasional: 610 h, Fungsionalitas: berfungsi sepenuhnya, 12 - Mesin pembilas 2 fase (air + udara);

12 - Katup pengisian elektro-pneumatik tekanan tinggi;

Penutup mahkota monohead untuk tutup crown 26 dan 26 twist-off;

- Screw universal untuk berbagai diameter botol.

- Pemandu samping bermotor

- Botol tiruan dengan penempatan manual untuk sterilisasi melalui mesin pembilas

- Botol tiruan dengan penempatan manual untuk sterilisasi pengisi

- Panel kontrol PLC dan layar sentuh

- Penyesuaian ketinggian listrik untuk semua unit

- Deteksi keberadaan tutup

- Unit pembilas botol di bagian keluar mesin

- Meja pengemasan sudah termasuk dalam harga

Mesin dalam kondisi sangat baik, telah diservis penuh, siap kirim.

Ffjdpfx Aoyh Rhdjbhsu

Menara penutup dapat dilengkapi dengan tutup ulir atas permintaan dengan biaya tambahan.

Iklan kecil

Przemyśl

Przemyśl

10.168 km

Mesin produksi minuman

COMPLETE PET BOTTLES ASEPTIC STILL/GASFILLING LINE KRONES

Hubungi

Kondisi: siap digunakan (bekas), VOLLSTÄNDIGE KRONES PET-FLASCHEN-ASEPTIK-ABFÜLLLINIE FÜR FRUCHTSÄFTE/GETRÄNKE UND SPRITZER.

GEEIGNET FÜR STILLE UND KOHLENSÄUREHALTIGE PRODUKTE.

BAUJAHR 2002–2007

LEISTUNG:

0,5 l x 36.000 Flaschen/Stunde

1,0 l x 30.240 Flaschen/Stunde

1,5 l x 25.200 Flaschen/Stunde

Flaschenverschlüsse: 28 mm

DIE LINIE UMFASST FLASCHENHERSTELLUNG, ABFÜLLUNG, ETIKETTIERUNG, VERPACKUNG UND PALETTIERUNG:

1. Steuereinheit: Ruland 2002, Touchscreen, Flash-Erhitzung & CIP/SIP

2. Pasteur: Ruland 2002, Rohrbündelwärmetauscher, 1.315 l Vorlagebehälter, max. 21.800 l/h

3. Steriltank: Roth 2002, 11.000 l

4. Karbonisator: Roth/Ruland 2002, 2.575 l, außer Betrieb

5. Stickstoffsystem: Terboven/ISTE 2002

6. Hygienic Center: Ecolab/Lang 2002, CAF, keine SPS

7. Sterilwassersystem: Roth/Ruland 2002, 9.000 l/h, Puffer 2.575 l

8. Sterilwassersystem: Roth/Ruland 2002, 9.000 l/h, Puffer 2.575 l

9. CIP/SIP: Ruland 2002, 20.000 l/h, 1.315 l Vorlagebehälter

10. Reinraum: Weiss 2002, Belüftung/Überdruck

11. Preform-Bunker: Dieterle 2002, MD3

12. Preform-Zuführung: Tanner 2002, HFT 4730 / RGT 1624

13. Streckblasmaschine: Krones Contiform S16 2002, 16 Stationen, 1,0–20.000 Fl./h

Fodpjxm Rwqsfx Abhsfu

14. Luftförderer: Krones 2002, automatische Schienenverstellung

15. Verschlussförderer: Gassner 2002, 2 Behälterstellen, Verschluss-Elevator

16–18. Füller: Krones CAF VODM 100 2002, Injektor (60), Ausspüleinrichtung (80), Füller (100), Verschließer (20), 1,0–20.000 Fl./h, 28 mm Verschlüsse, still/kohlensäurehaltig

19. Etikettenkontrolle: Krones 2002, integriert im Prontomodul

20. Flaschenkontrolle: Krones 2002

21. Transportband: Krones 2002, Gebläse vor Etikettiermaschine

22. Etikettiermaschine: Krones Prontomodul 2007, max. 35.600 Fl./h

23. Canmatic-Modul: Krones 2007, Papieretiketten

24. Contriroll-Modul: Krones 2007, Folienetiketten

25. MHD-Kodierung: Videojet Excel/170i

26. Schrumpfpacker: Krones Variopak 2002, 0,5–36.000 Fl./h, Kartonzuführung & Folientransport

27. Verpackungsförderer: Krones 2002

28. Tragegriffapplikator: Twinpack MHTE 2002

29. Leerpalettenmagazin: Krones LPM 2002

30. Palettierer: Krones Roboter 3A Loader 2002, 4.000 Gebinde/h

31. Palettenfördertechnik: Krones 2002, Übergabewagen & Dreheinheit

32. Leerpalettenmagazin: Krones LPM 2002

33/34. Palettenwickler: Franpak 2002, Obenblattaufleger

35. Umreifungsmaschine: Bornbinder HB 2002

36. Palettenkodierung: Logopak EAN 128 2003

DIE ANLAGE IST NOCH NICHT DEMONTIERT, SEHR GUTER ZUSTAND. STANDORT: DEUTSCHLAND.

Iklan kecil

Łask

Łask

10.424 km

Kompleks Pembersih Mobil Ozon Bergerak

CeletteTrioxyclean

Hubungi

Tahun pembuatan: 2023, Kondisi: baru, Kompleks mobile untuk pembersihan mobil dengan ozon model Celette Trioxyclean, Prancis. Tersedia 6 unit. Secara cepat dan menyeluruh menguraikan senyawa organik volatil berbahaya di dalam mobil seperti formaldehida, amonia, benzena, TVOC (Total Volatile Organic Compounds), dll., menghilangkan bau tidak sedap dari asap rokok, alkohol, dan makanan, secara efektif membunuh bakteri dan virus yang melayang di udara, serta melindungi penumpang dari infeksi silang. Output ozon (O3): 5000mg/Jam Ion negatif: 8 – 10 Juta Konsentrasi ozon: 15-25mg/L Tingkat sterilisasi: 99,99% Tipe pendinginan: pendingin udara Suplai daya: 220/110 Volt | 50Hz/60Hz Berat: 37 KG Dimensi (P x L x T) cm: 55 x 40 x 126

Ffjdpfxou Dpygs Abhju

Iklan kecil

Jerman

Jerman

11.023 km

Autoklaf

Stock dftDAX 1400-2 BV-VA-WT

Hubungi

Tahun pembuatan: 2020, Kondisi: siap digunakan (bekas), 1

Fjdpfx Ajyh Nvgebhsfu

Iklan kecil

Jerman

Jerman

11.023 km

Generator uap murni

Finn Aqua500 H1

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 1986, Performance at 45 PSIG: 440 kg/h, max. pressure: 8 bar, max. temperature: 121°C, material: stainless steel, steam: sterile, machine dimensions (L/W/H): approx. 1200mm/800mm/2850mm. An on-site inspection is possible.

Ffodpfxjugmwfo Abhju

Iklan kecil

Jerman

Jerman

11.023 km

Wasserdestillationsanlage

Concept GMPAquaInject MD 300 C4 N

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 2018, de-eingangsmedium-ap-wasser-destillationsanlage

Ffedpfx Aboygmcdshou

Iklan kecil

Jerman

Jerman

11.023 km

Sistem pengisian, pelabelan dan pengemasan

Stork/Silmo/Robino & Galandrino/AdelskiVV-24/ST XII/Monoblocco Fenix 3/P2004 Longcap

Hubungi

Tahun pembuatan: 2007, Kondisi: siap digunakan (bekas), A complete bottling, sterilization, capping, labeling, cartoning, and palletizing line for the wine industry is available. Bottle filling capacity: 4,000 bottles/h, bottle format sets: 1L and 0.75L Schlegel/Bordeaux/Burgundy/0.5L/0.25L, sterilizer capacity: 4,000 bottles/h, capsule applicator capacity: 8,000 bottles/h, labeling capacity: 10,000 bottles/h, capping capacity: 10,000 bottles/h, carton formats: 12-bottle and 6-bottle case/carton, palletizer capacity: 1,000 cartons/h.

Ffsdpfx Ajvur Htobhsu

Line components:

1) Carton folding machine Normpack Compact Form CF 670/980, year: 2000, capacity: approx. 650 cartons/h

2) Bottle filling machine Stork VV-24 L.W., year: 1977

3) Immersion sterilizer Silmo ST XII/110 with ozone, year: 1983, bottle formats: all standard wine bottles

4) Caustic solution testing device Miho LC 2000, year: 2003

5) Capsule applicator Robino & Galandrino Monoblocco Fenix 3, year: 2002

6) Closure inspection system Syscona Unicount with counter for cork and metal closures

7) Labeling machine Garnep Lebetta 4/3/18 1320, year: 2017, including 2x wet glue units, 3x self-adhesive label units, camera system for coarse bottle alignment and Domino laser for imprinting

8) Automatic capping machine Adelski PP2004 Longcap, year: 2007

9) Automatic capping machine Adelski MCA PV 6541/1/210 AVM2104, year: 1999

10) Corker Bertolaso Delta, year: 1977

11) Carton sealing machine Normpack NCF-047, year: 2001, including hot melt applicator

12) Packaging machine Kettner Robot Junior Packer BE 2-T, year: 1992

13) Palletizer Kettner Pressant Universal 1200, year: 1992

14) Case labeling machine Weber Legi-Air 40XX, year: 2004

15) Dryer Okema T3, year: 1999

16) Carton printing machine Blum CompactLine 3.0, heads: 8, printing options: double-sided

17) Ozone generator Silmo 40g, year: 1983

18) Glass handling machine Schaberger, year: 1977, including new glass head, 12-case head, and bottle table.

Documentation available. On-site inspection possible.

Iklan kecil

Jerman

Jerman

11.023 km

Bierkeg-Wasch- und Füllsystem

Leifeld und Lemke20l/30l/50l

Hubungi

Kondisi: siap digunakan (bekas), Tahun pembuatan: 1988, A complete keg cleaning and filling line by Leifeld + Lemke, now IW-Anlagentechnik, is available. Throughput: approx. 120 kegs/h; keg/barrel formats: 20L/30L/50L; control system: Siemens S7; control system retrofit: 2008. 1) Keg/barrel external cleaning machine Schöttiger + Schäfer KHAH 240, max. cleaning output: 240 kegs/h, operating cleaning output: 140 kegs/h, drive rollers: 2, transfer rollers infeed/outfeed: 1/1. 2) Keg/barrel pre-cleaning machine Leifeld + Lemke KVR 300, year of construction: 1988, max. washing output: 180 kegs/h, operating washing output: 120 kegs/h, design: stainless steel, process: centering, residual draining with air purge, mixed water pre-cleaning, waiting and soaking station, caustic cleaning and pre-filling. 3) Keg/barrel main cleaning and filling machine Leifeld + Lemke KFR 401, year of construction: 1988, filling line output: 60 kegs/h, design: stainless steel, process: centering, internal cleaning station, 2 sterilisation points, pre-fill preparation, filling station, waiting station. 4) CIP cleaning station for barrels, max. cleaning output: 180 kegs/h, cleaning agent tanks: 5, tank volume: 650L, tank contents: caustic 1/caustic 2/acid/hot water/mixed water. The system also includes the complete pallet conveyor, keg transport, and a KUKA robot for automated palletising and depalletising of the kegs. Documentation available. Inspection on site is possible.

Fedpfx Aeycigkobhefu

Segel kepercayaan

Dealer resmi yang disertifikasi oleh Machineseeker

Iklan kecil

Wald

Wald

11.178 km

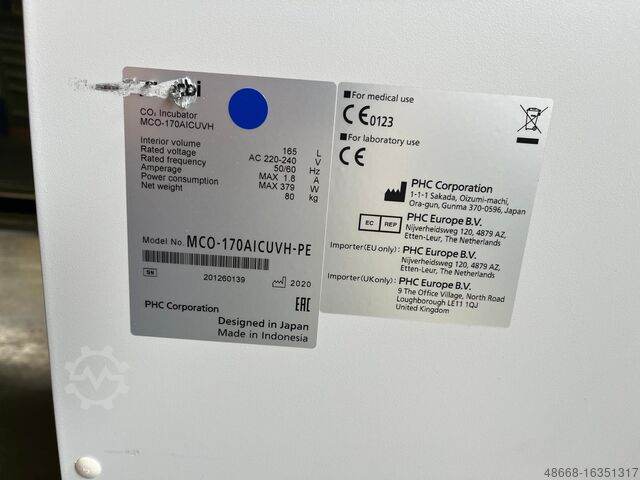

Kabinet inkubator CO2 H2O2

PHCbiMCO-170AICUVH-PE

Hubungi

Tahun pembuatan: 2021, Kondisi: bekas, en-PHCbi MCO-170AICUVH-PE CO2 Incubator Cabinet H2O2 Decontamination

Temperature range: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of manufacture: 2021

Dimensions: 650 mm x 620 mm x 1000 mm (external)

480 mm x 500 mm x 650 mm (internal)

Weight: approx. 80 kg

PHCbi

Successful cell culture requires an incubator that offers a high level of precision and safety while being easy to operate. IncuSafe offers a range of cell culture incubators featuring advanced technologies for unprecedented temperature and CO2 (and, in some models, O2) control during the processing of various cell cultures. These units deliver long-term performance and are extremely reliable and efficient.

- inCu-saFe® Chamber (proactive contamination control, copper-enriched stainless steel alloy): Combines the germicidal properties of copper with the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: The UV lamp, isolated from the cell cultures, decontaminates the circulating air and the water in the humidification tray without damaging the cell cultures.

- H2O2 Decontamination Technology: The unique high-speed decontamination system from PHCbi uses gaseous H2O2, enabling time-saving and documented chamber decontamination with a high degree of safety. Electronic door lock automatically secures the chamber during the decontamination phase.

- Dual hot-air sterilization (+180 °C). No interruptions or impairment of operational performance in stacked incubators during the sterilization cycle (Model: MCO-170AICUVD-PE).

- Long-lasting performance, optimal cell viability, and successful experiments. Additionally, precise control of CO2 concentration and temperature is ensured with straightforward operation and maintenance.

- Patented DHA direct heating and air-jacket system*: High-precision temperature control for enhanced temperature uniformity and rapid temperature recovery after door openings.

Ffedpfx Aetxakxjbheu

- Rapid CO2 recovery: Ultra-fast CO2 recovery without overheating, thanks to the PID controller and dual infrared sensor—even after multiple door openings.

- The unique solid-state zirconia O2 sensor in the multigas incubators enables precise regulation of physiological oxygen concentrations to simulate in vivo conditions.

Description as provided.

You are welcome to arrange a viewing.

We can organize cost-effective shipping for you!

You will receive a proper invoice.

For international customers, a net invoice (excluding VAT) can be issued—provided you supply a valid VAT ID number.

Subject to prior sale.

Visit our shop to view more of our offers.

All company names and trademarks are property of their respective owners and are used for identification and description purposes only.

Deviations from technical data and errors in the item description may occur and are reserved.

Iklan kecil

Wald

Wald

11.178 km

Kabinet inkubator CO2 H2O2

PHCbiMCO-170AICUVH-PE

Hubungi

Tahun pembuatan: 2020, Kondisi: bekas, en001

Ffodjtxaczepfx Abhju

Iklan kecil

Wald

Wald

11.178 km

Kabinet inkubator CO2 H2O2

PHCbiMCO-170AICUVH-PE

Hubungi

Tahun pembuatan: 2020, Kondisi: bekas, en-UK

Ffjdpfxetxarco Abhsu

Iklan kecil

Fumane (Verona)

Fumane (Verona)

11.094 km

Lini pengisian lengkap bekas untuk botol kaca farmasi - 3500 botol per jam

SIDE SBM

Hubungi

Kondisi: bekas, Tahun pembuatan: 2000, nomor mesin/kendaraan: LC593, Technical Specifications & Performance Data

This used filling line is a complete, pre-owned pharmaceutical packaging solution designed for filling and packaging glass bottles for infusion applications. The line is currently in operation and supports multiple dosing formats with integrated washing, filling, capping, crimping, sterilization, inspection, labeling, cartoning, and palletizing. For sterile handling, purified water (PW), water for injection (WFI), and sterile compressed air are used in critical sections.

Production speed: 3,500 bottles per hour

Supported bottle volumes: 0.2L, 0.25L, 0.4L, 0.5L

Container type: Glass bottles (infusion/IV style)

Line configuration: Depalletizer, bottle washer (PW/WFI + sterile air drying), filler, vacuum stage, bottle capper, aluminum crimping machine, tray loader, autoclave, tray unloader, 2 x manual inspection stations, labeling machine, cartoning machine, case sealer, palletizer

Sterilization: Autoclave from SBM

Operational status: In production

Advanced Automation & Control Systems

The line is equipped with integrated handling and synchronized conveyors to ensure continuous flow through washing, filling, closing, and final packaging. Manual visual inspection stations are positioned downstream of sterilization to ensure product quality. Format changeover is designed for multiple bottle sizes from 0.2L to 0.5L, enabling efficient batch changes. Standard pharmaceutical best practices such as sterile air drying and separation of clean utility media support controlled operations. Electrical parameters and PLC/HMI specifications are line-dependent and can be adapted to local plant infrastructure.

Production Line Integration Features

As a complete packaging line, this system operates in sequence from depalletizing to palletizing. Upstream sections prepare and clean glass containers, intermediate modules handle precise filling and secure capping with crimping, and the downstream area undertakes sterilization, inspection, labeling, cartoning, sealing, and palletizing. The line offers multi-format flexibility for glass bottles (0.2L, 0.25L, 0.4L, and 0.5L) and can be integrated into site-specific quality management and traceability systems. Conveyors and accumulation zones are configured to balance the process step cycle times.

Machine Condition & Maintenance History

The line is currently in operation, indicating ongoing functionality and a well-maintained condition. Cleaning with PW/WFI and sterile air drying highlights disciplined hygienic routines aligned with pharmaceutical processes. The regular operation of all stations—from depalletizer to palletizer—demonstrates a cohesive, production-ready asset that can be immediately deployed following site-specific adaptation.

Fsdpsydpa Tefx Abhjfu

Operational Performance & Versatility

Designed for glass bottles and sterile liquid products, the line combines high throughput, process reliability, and multi-format flexibility, making it suitable for pharmaceutical production environments requiring both adaptability and compliance with strict regulatory standards.

Kami memudahkan pencarian untuk Anda: "sterilizer"

Anda akan menerima penawaran baru melalui email secara langsung dan gratis.

Anda dapat mengakhiri tugas pencarian kapan saja.

Bekas Sterilizer (202)

Sekarang telusuri seluruh Machineseeker dengan lebih dari 200.000 mesin bekas.Jelajahi nama mesin paling populer:

Informasi sekarang

+44 20 806 810 84

+44 20 806 810 84

Pasang iklan sekarang

*per iklan/bulan